Lot-size-flexible manufacturing technologies and assurance of the manufacturing quality of polymer implants

In recent years, medical innovations have been developed by a large number of industrial companies and research institutes as part of various RESPONSE research projects. In this way, the project lays the scientific and technological foundations for the societal value creation that RESPONSE aims to achieve on the path from research result to medical product.

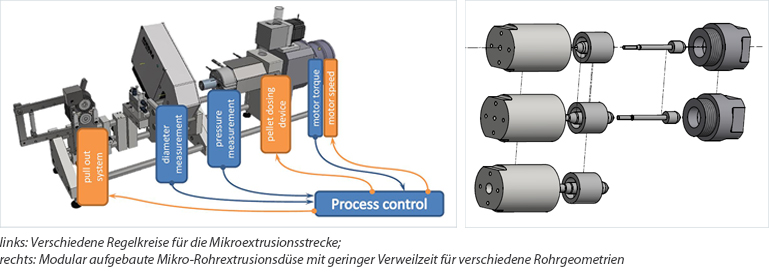

In the project supervised by the Kunststoff-Zentrum (KUZ), methods of material-flexible small-volume production are being developed in the field of microextrusion. The project includes the design and testing of a modular micro pipe extrusion die with low dwell time for different pipe geometries. This die can be adapted to various micro and small-volume extruders and will be tested within the scope of the project both on the compact extruder of the KUZ and on a microcompounder of the IBMT Rostock. For further testing for batch size and geometry flexibility, individualized filaments are produced for the application field 3D printing using the FDM process, which is being tested by a project partner from the RESPONSE network. Furthermore, process data acquisition and various control loops for the extrusion line are being set up and tested.

In addition, in the field of micro injection molding, exemplary process chains for injection molded micro parts are being designed, following impulses from the RESPONSE working group. In addition to the criteria for production-oriented design, the thermal and mechanical stresses on the melt are also being investigated.

Contact

Dr. Gábor Jüttner

0341 4941 762 | juettnernoSpam@kuz-leipzig.de

Funded by the German Federal Ministry of Education and Research

FKZ: 03ZZ0933E