Plastics - Insulator or conductor, as required

Electrical tests

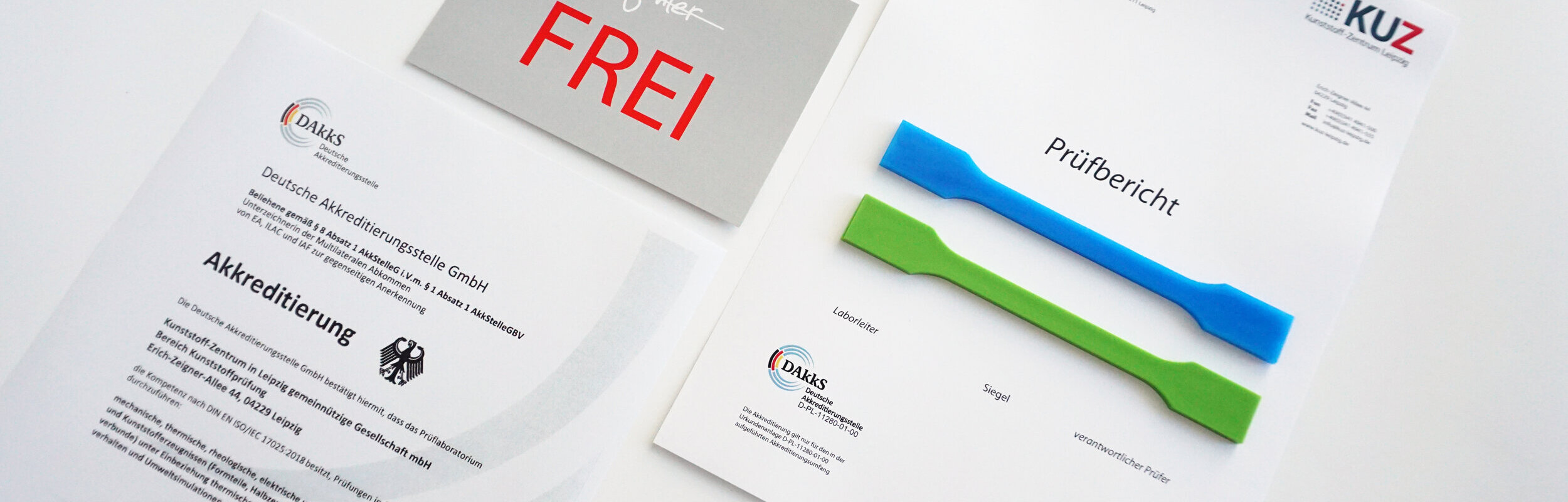

Plastic components combine an increasing number of functions in electrotechnical applications. Functionalized plastic components include insulators, heat conducting elements and user interfaces. To ensure the intended function and safety of the application, various electrical tests are required prior to use. The KUZ addresses oneself to the testing of functionalized plastic components and to the further development of various electrical testing methods in application-oriented research projects as well.

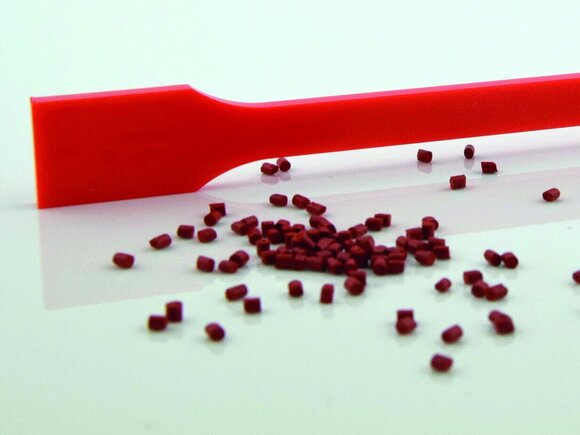

- Dielectric strength (high voltage tests)

The application of plastics as insulators requires the determination of their dielectric strength. The dielectric strength of materials is already measured in the accredited test laboratory up to 70 kV DC and up to 50 kV AC in accordance with DIN EN 60243, however, these values are far from being at the end of our research. Our focus is on the suitability of modern highly filled plastics as thermal conductors and electrical insulators. Furthermore, the dielectric strength of entire components and assemblies can be investigated.

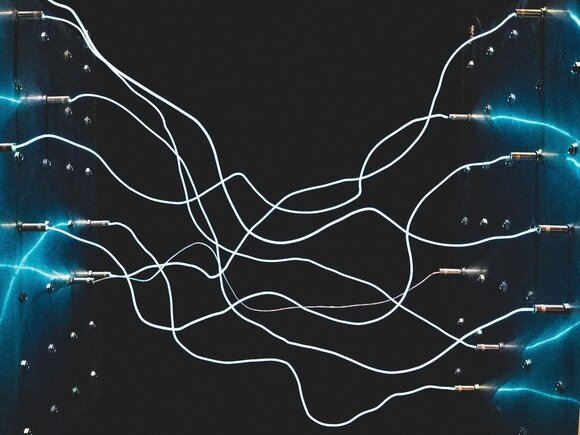

- Volume and surface resistance

Conductive or non-conductive? Different functions require different material properties. The current seeks its shotest path through the component and along its surface resistance, respectively. The KUZ offers testing of these properties according to DIN EN 62631-3-1. Conductive materials can also be investigated with our equipment. Here the standard DIN EN ISO 3915 is applied.

Our research focuses on the behavior of highly functionalized sandwich components with migrating antistatic agents.

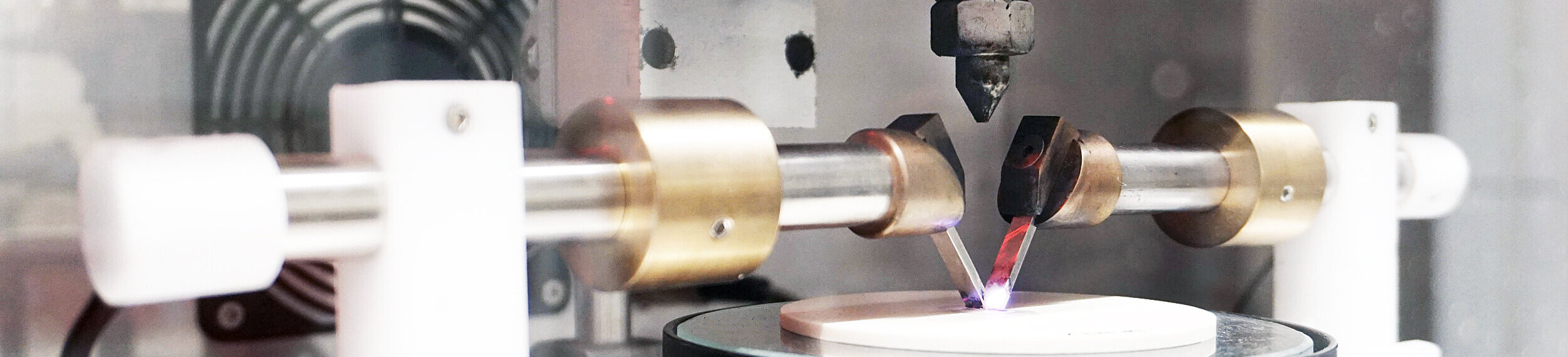

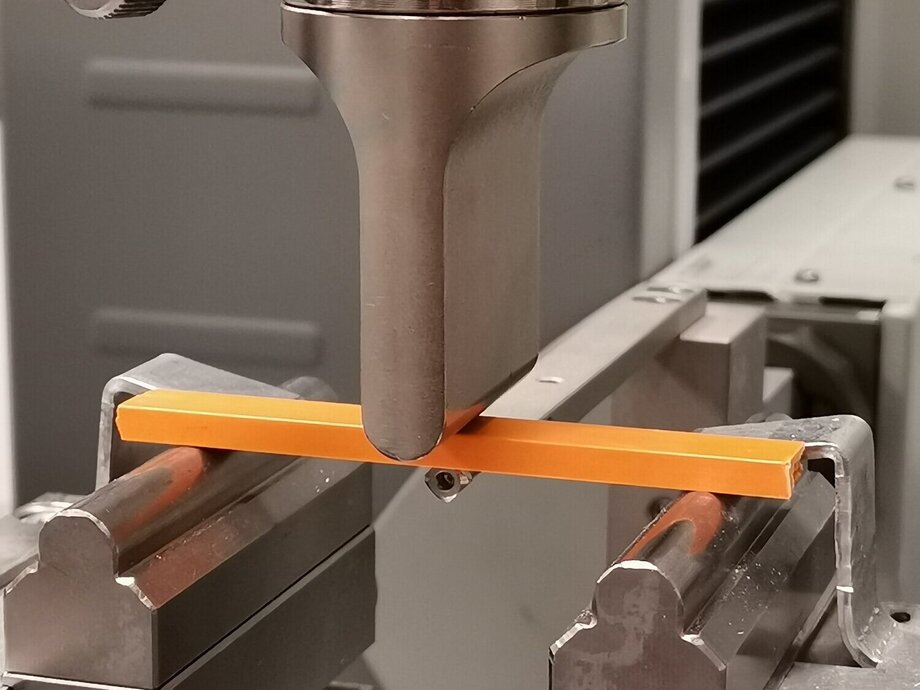

- Tracking resistance

The creepage resistance is the CTI value (comparative number of creepage) or the PTI value (test number of creepage). This can be tested up to 600 V according to DIN EN 60112. In thigh-voltage applications such as electromobility or in the field of regenerative energies, the use pf plastics as insulators requires to overcome this limitation. Therefore, we are working on the development and qualification of a tracking resistance test device up to 950 V within our research. Furthermore, the effects of the high voltages are being investigated as well. As a result, charging infrastructures made of high-tech plastics, for example, can be tested in a more application-oriented manner.

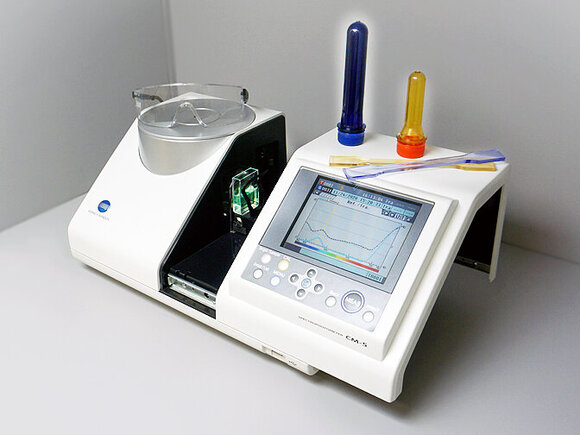

- Dielectric properties

In order to assess the suitability of plastics in the field of cable sheathing, housings or in capacitors, the dielectric constant or dielectric loss factor of the material is often used. These values describe the permeability of electromagnetic fields through the plastic. In the KUZ, the dielectric values of plate-shaped sample material can be determined in a frequency range from 20 Hz to 15 MHz at room temperature according to DIN EN IEC 62631-2-1.

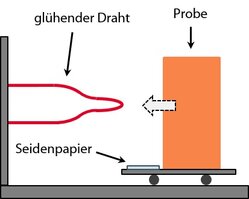

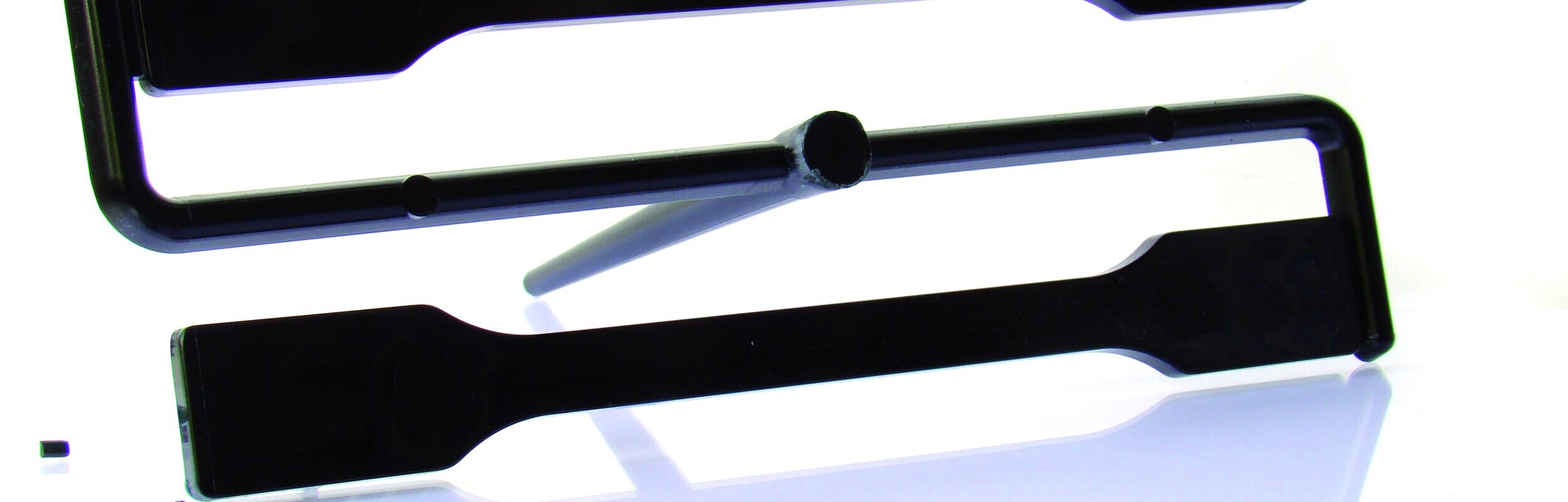

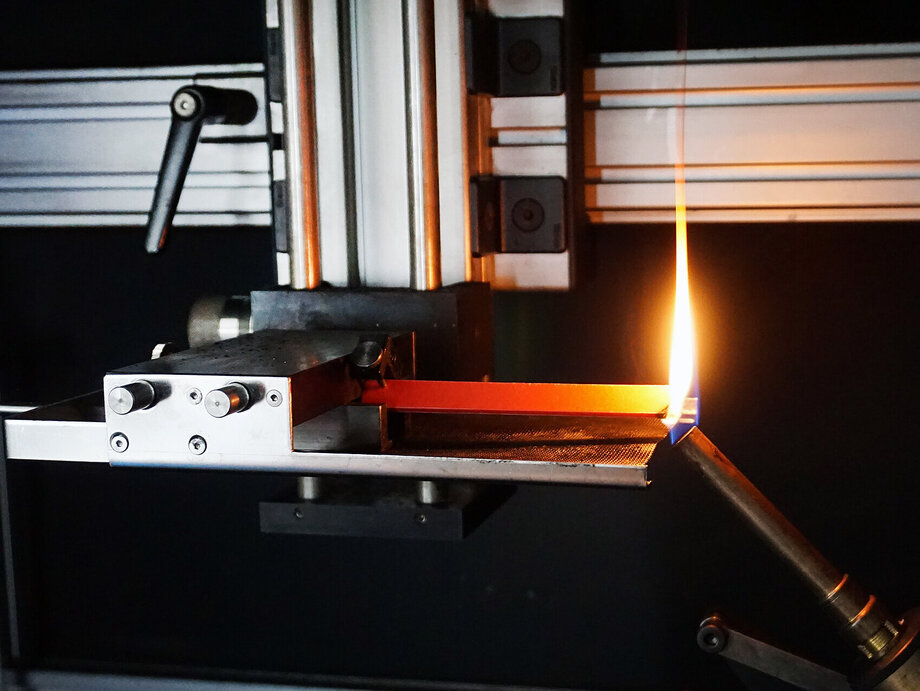

- Flammability tests of plastic housings

In addition to the task of insulating electrical equipment, plastics also protect against flames caused by electrical malfunctions or short circuits. Flames may break though outside the housing in the event of fires. For this purpose, the KUZ test laboratory offers fire tests according to UL94 (or DIN EN 60695-11-10) for applications in the E&E sector, as well as glow wire tests according to DIN EN 60695-2-11/12/13, among others.

Our equipment at a glance

High voltage tester DT2-50-20-SR-Pi-C-Sg

Dielectric strength tester

Sefelec

2101 Conversion FE

Leakage current tester

Lindenblatt

Milli-and TeraOhmmeter TO3

Resistance measurement

Fischer Elektronik

GPG 3

Glow wire tester

Fischer Elektronik

"/>

"/>