Characteristics for processability and flow behavior

Rheological tests

Plastics exhibit viscoelastic behavior. This means that they exhibit neither properties of an ideal-elastic solid nor of an ideal-viscous liquid. The KUZ test laboratory has available various rheological testing and investigation methods. They are applied to characterize the flow behavior in the shear rate range relevant to processing and also to investigate the quiescent structure of the polymer at very small deformations or deformation rates.

Our services for rheological testing in detail

Our equipment at a glance

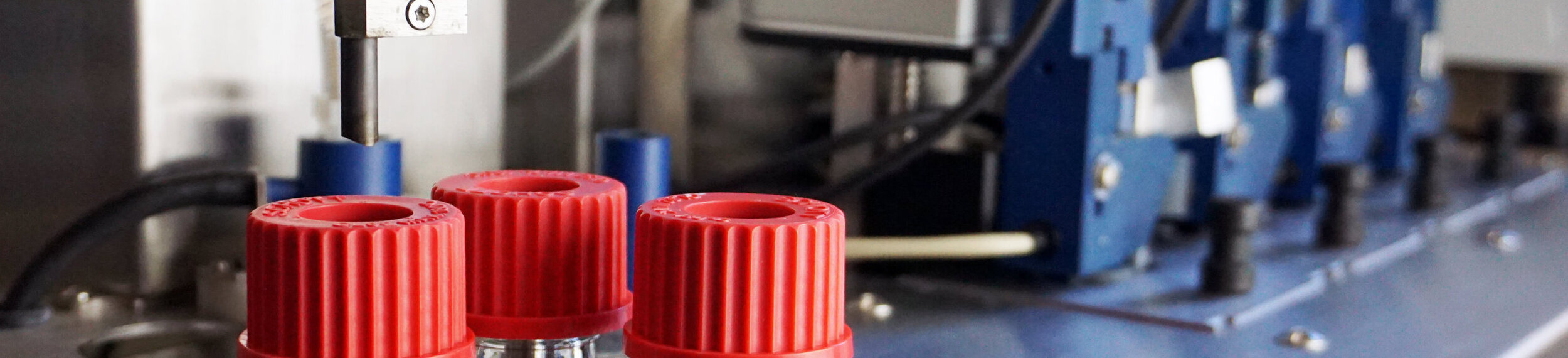

Melt flow rate tester

MI-3

Göttfert

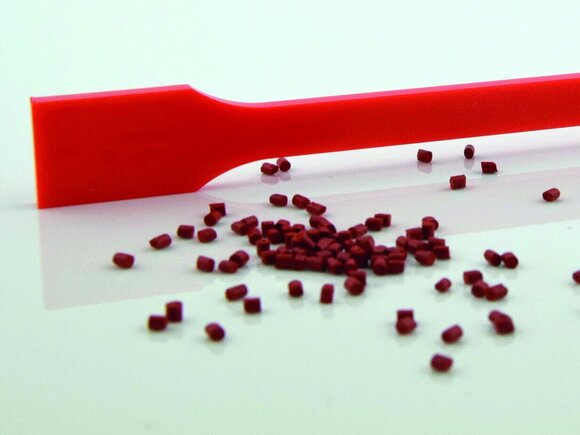

Solution viscosity

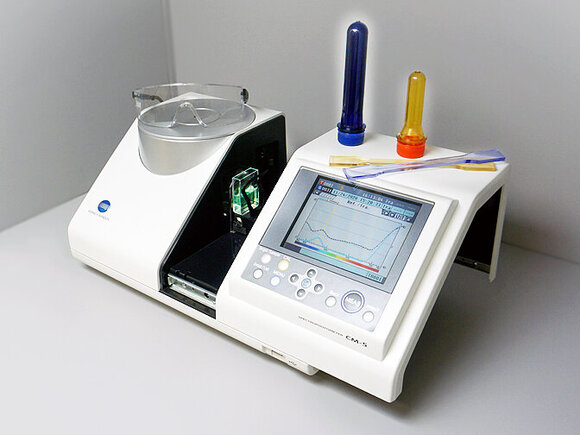

Viscosity measuring system PVS 1

Lauda

Melt, rotation, oscillation rheometer

MCR 502

Anton Paar

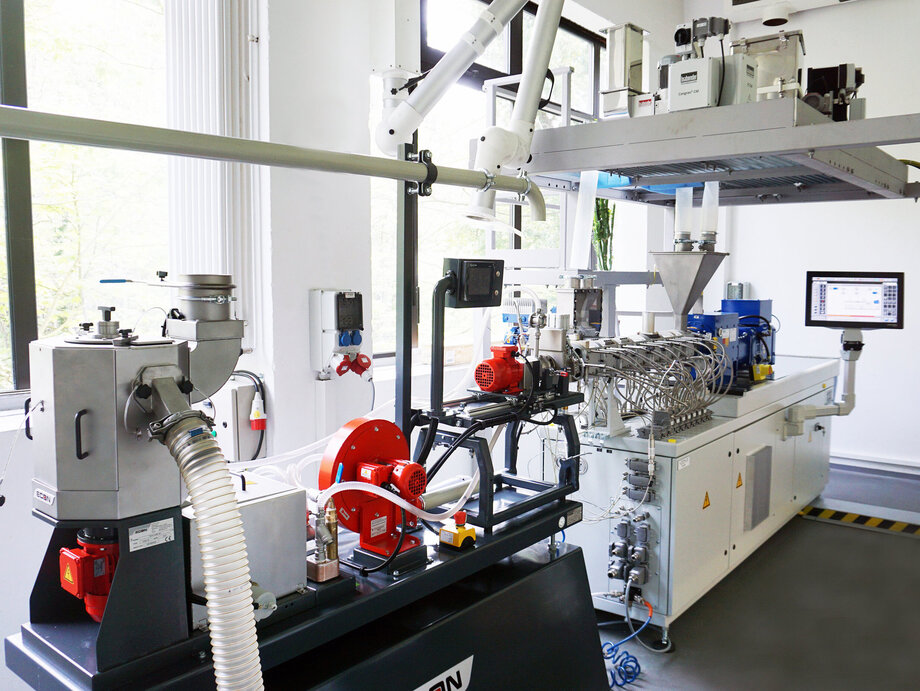

Melt online rheometer

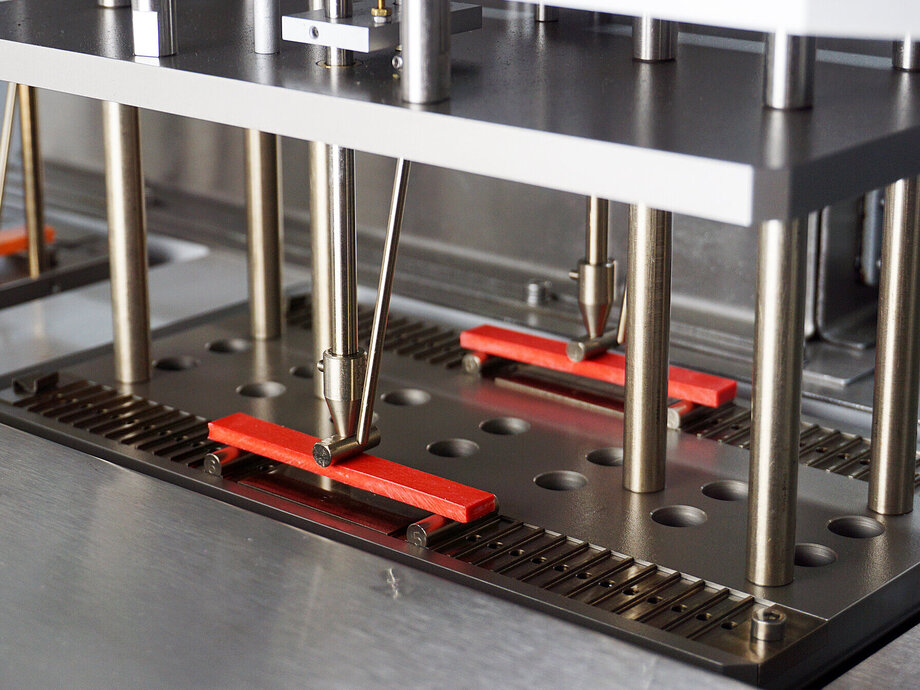

Injection molding rheometer

KUZ

"/>

"/>