Customizing plastics

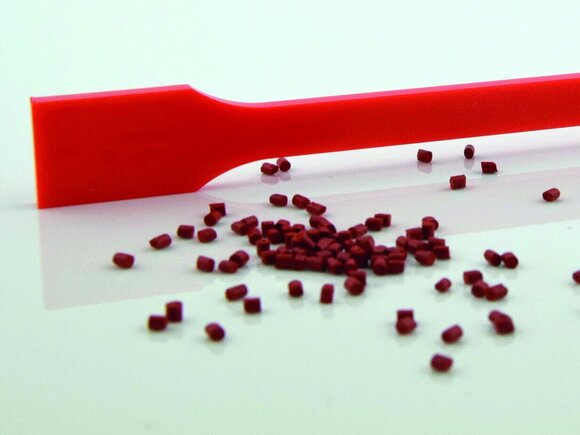

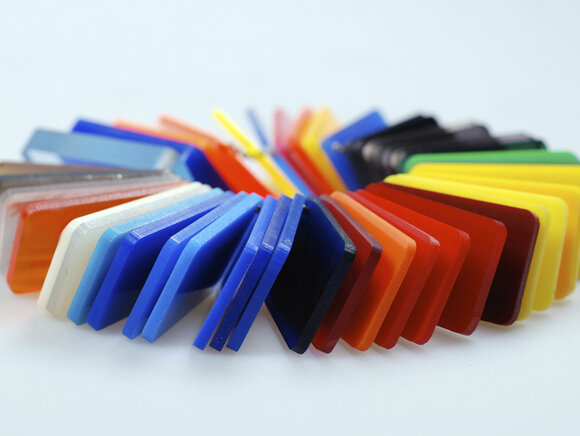

Compounding

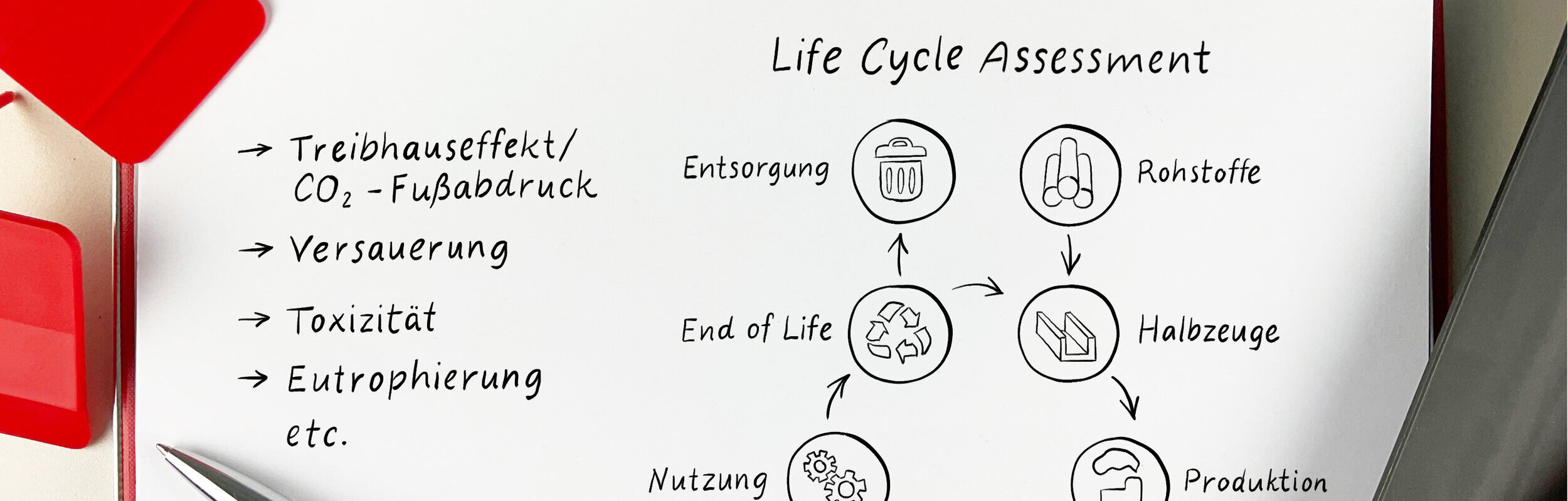

The speed at which new trends lead to changing customer requirements and new products and innovations is constantly increasing. New developments of corresponding materials are expensive and not always necessary. In order to remain flexible and to be able to react actively to changing requirements, the modification of existing plastics with appropriate additives is an option.

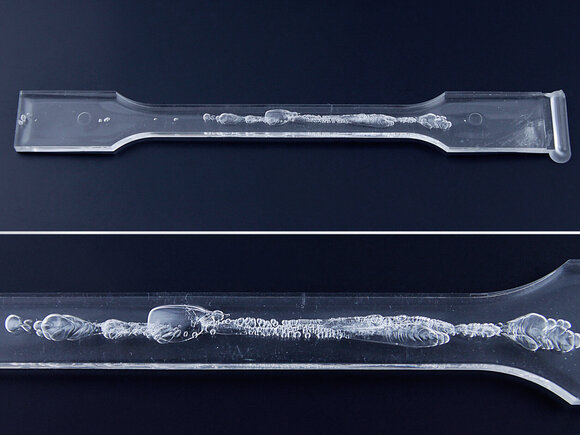

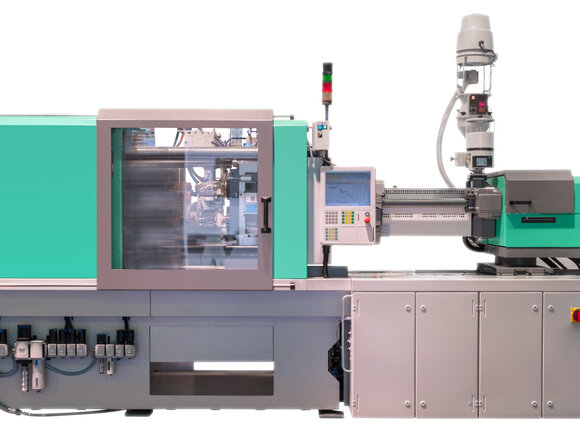

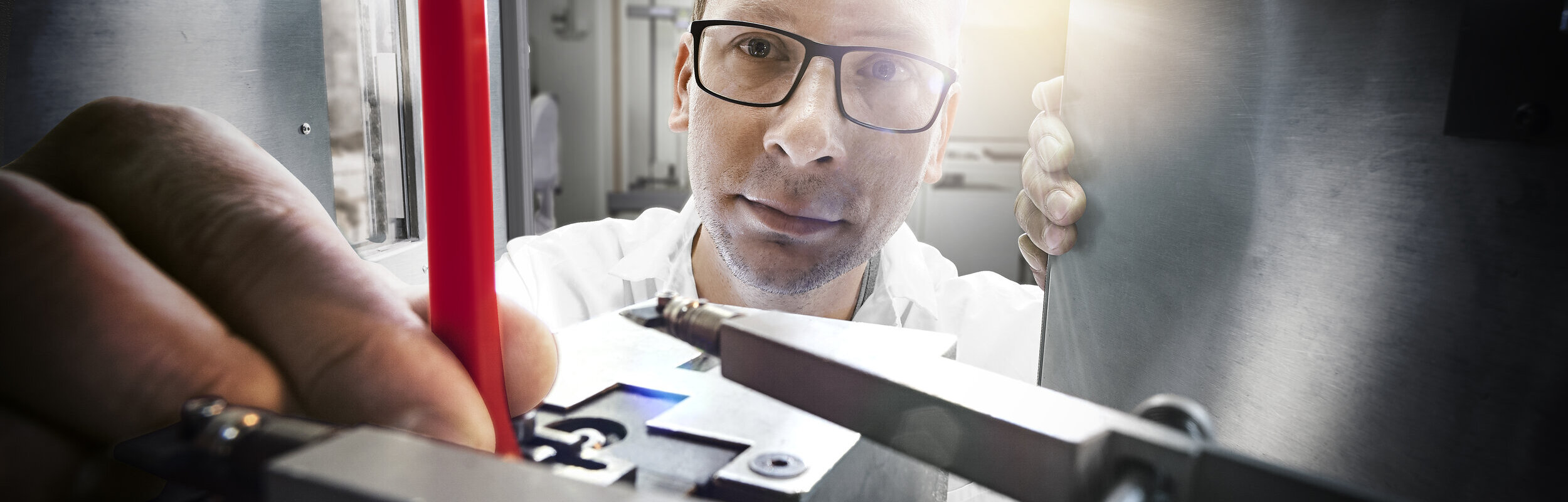

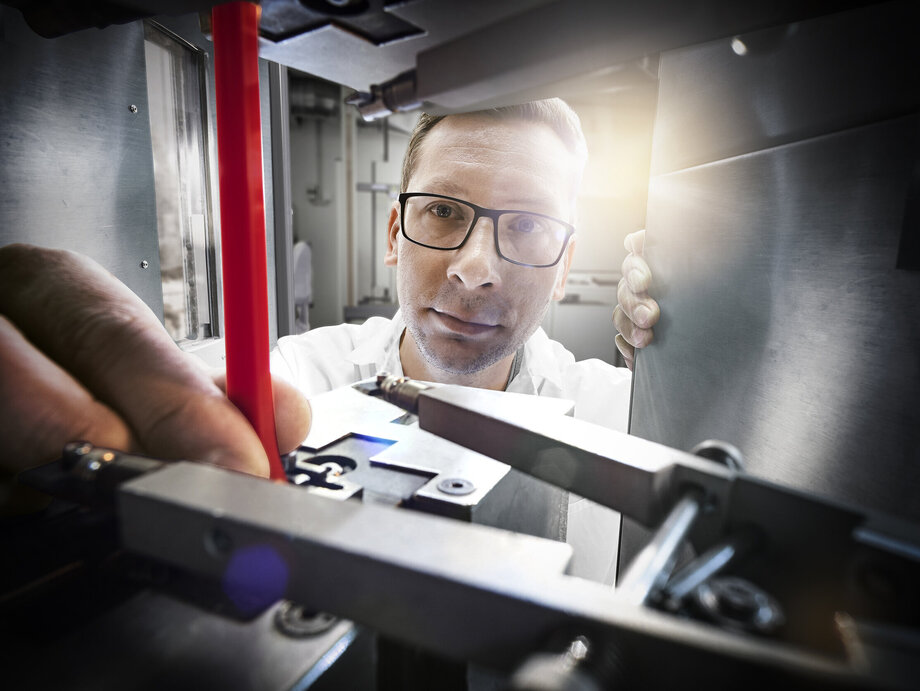

The customized compounds produced by twin-screw extrusion are evaluated and optimized with regard to rheological, mechanical and processing changes until the plastic fits. In addition to plastic modification, we are also intensively pursuing the development of novel, sustainable materials. The focus here is on the generation of bio-based plastics and the processing and property optimization of recycled materials. The interaction with the process design of subsequent manufacturing processes is important here. With its wide range of expertise and equipment, the KUZ can cover all eventualities in practice and thus tailor the material to the optimum in the process and in the product.

Our compounding services in detail

Our machine equipment at a glance

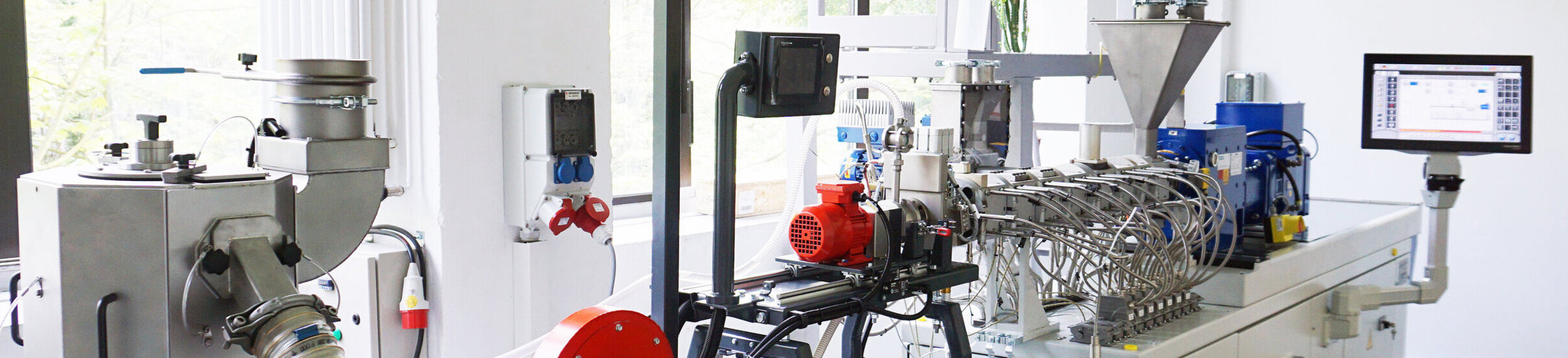

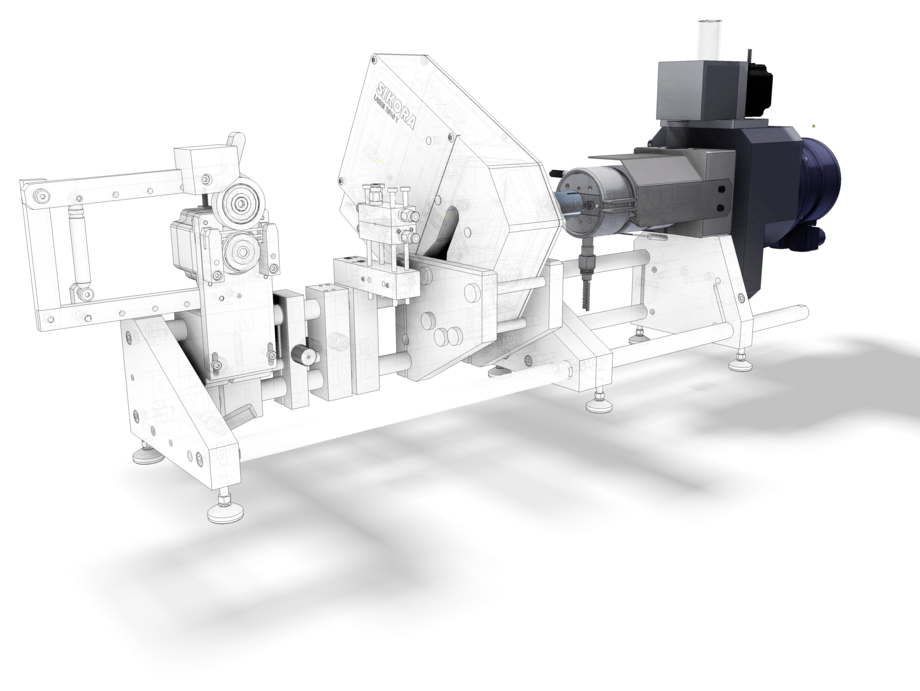

Twin-screw extruder

ZE25A-UTXi with 47D

KraussMaffei Berstorff

2 x gravimetric feeders for polymer components

DDW-M-F40

Brabender

Gravimetric feeder for fillers, reinforcing materials

DDW-M-DDSR20

Brabender

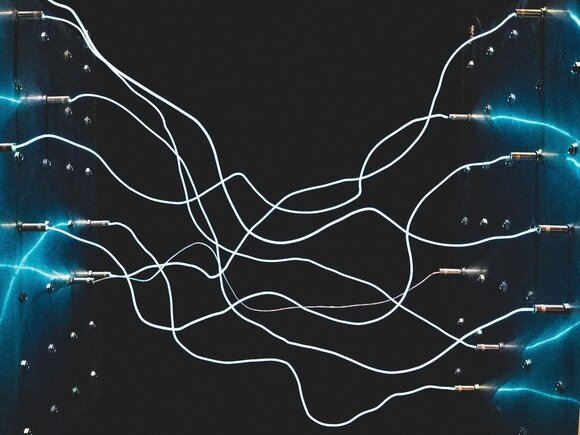

Liquid dosing including preheating station for higher viscosity fluids

P80

Knauer

Hot die face pelletizer / underwater, air pelletizer

EWA10

Econ

Cold cut granulator / strand granulator, cold granulator / water bath

Primo 60E

Rieter

Extrusion Rheometer

Rheomex 19/10 OS

ThermoFisher Scientific

Torque rheometer

Rheomix OS

ThermoFisher Scientific

"/>

"/>