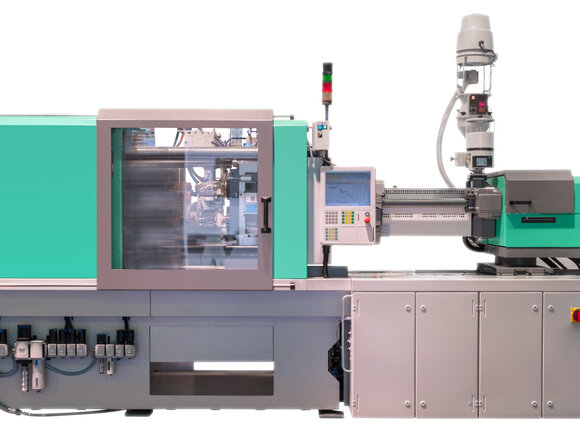

Along the value chain

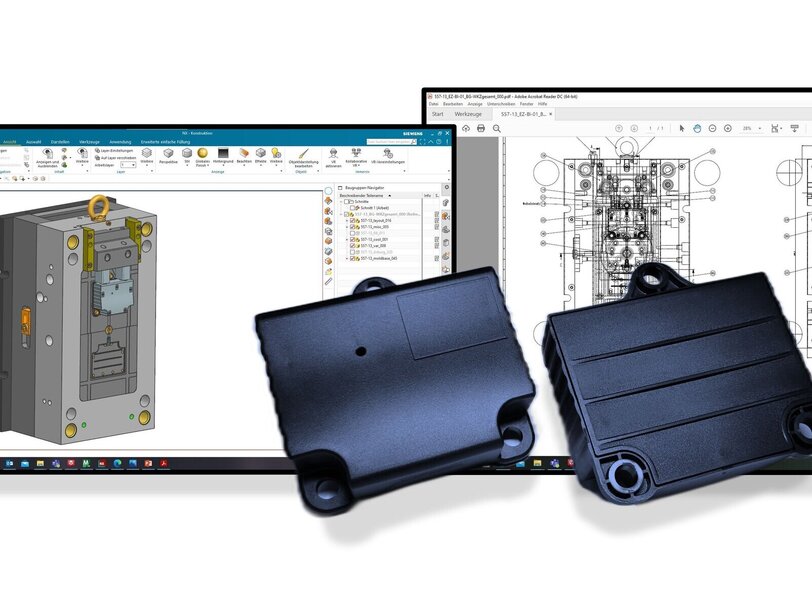

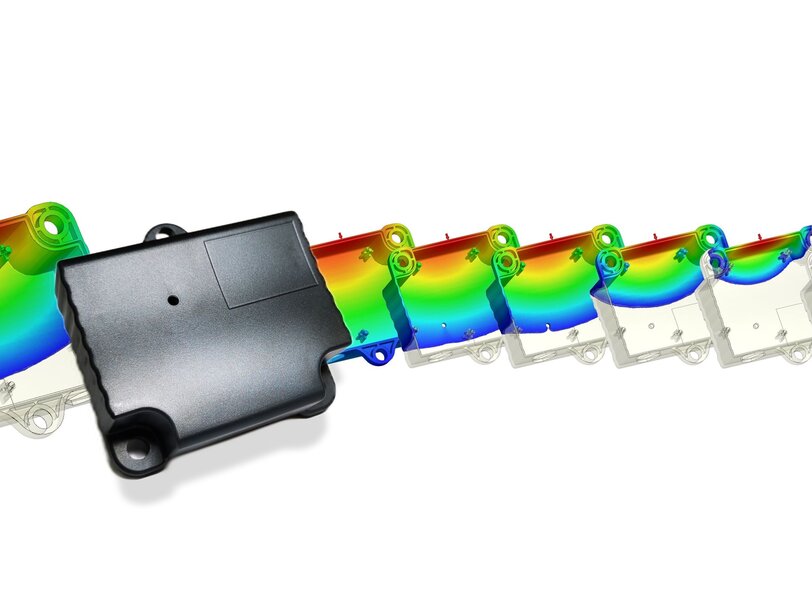

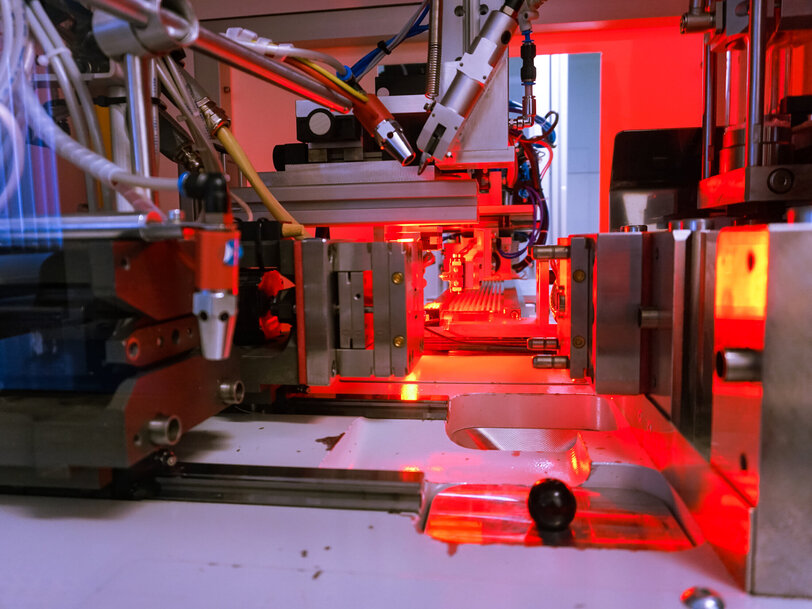

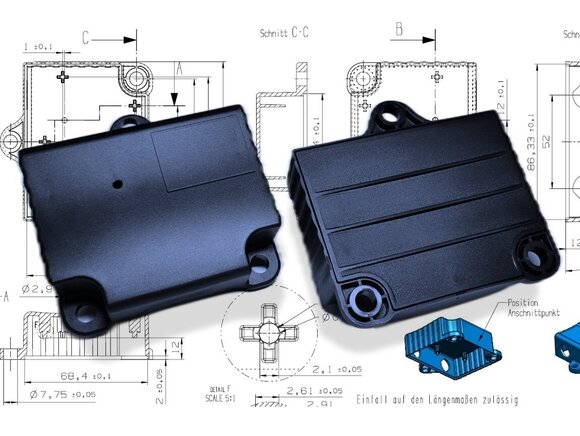

Engineering

Accelerate your product development and manufacturing processes. We accompany you through all development phases, starting with the idea generation up to the finished serial product and the corresponding manufacturing technology. We attach great importance to an uncomplicated and goal-oriented approach. With our available CAE services, your development process will be streamlined in terms of time, as well as efficient and sustainable.