small steps - BIG impact

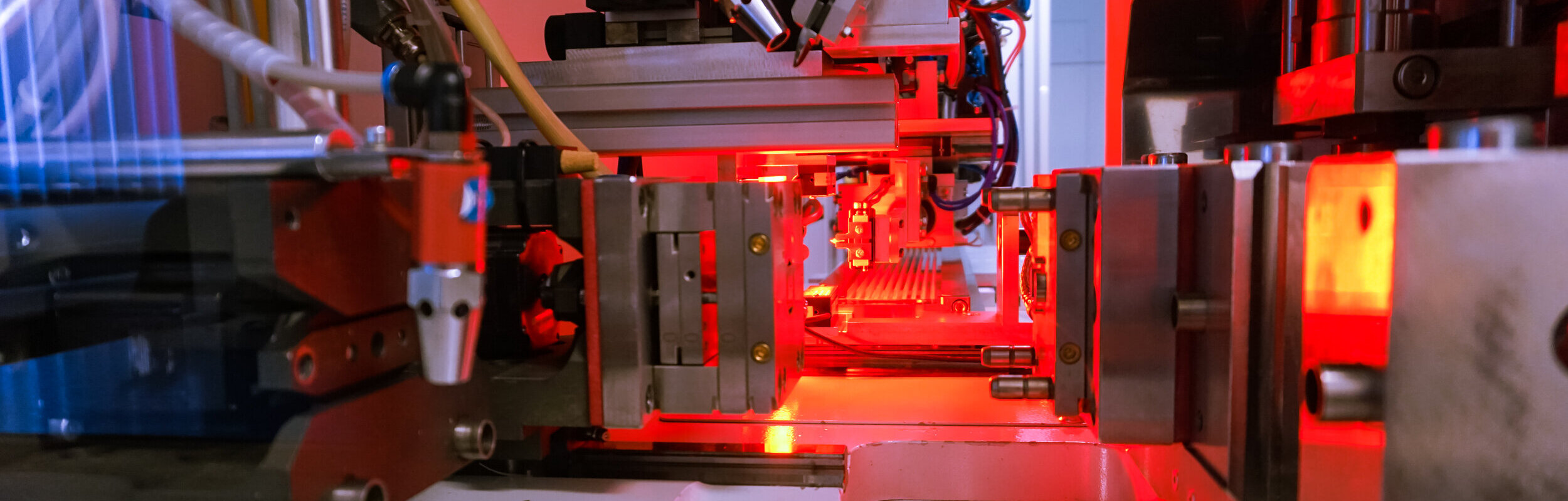

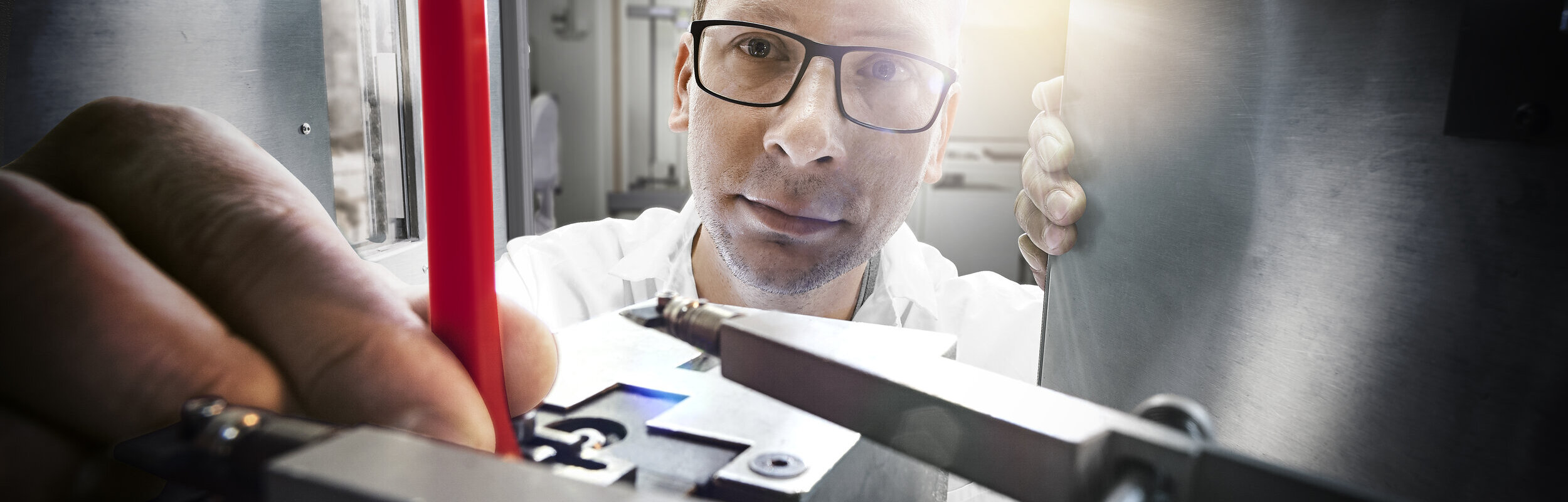

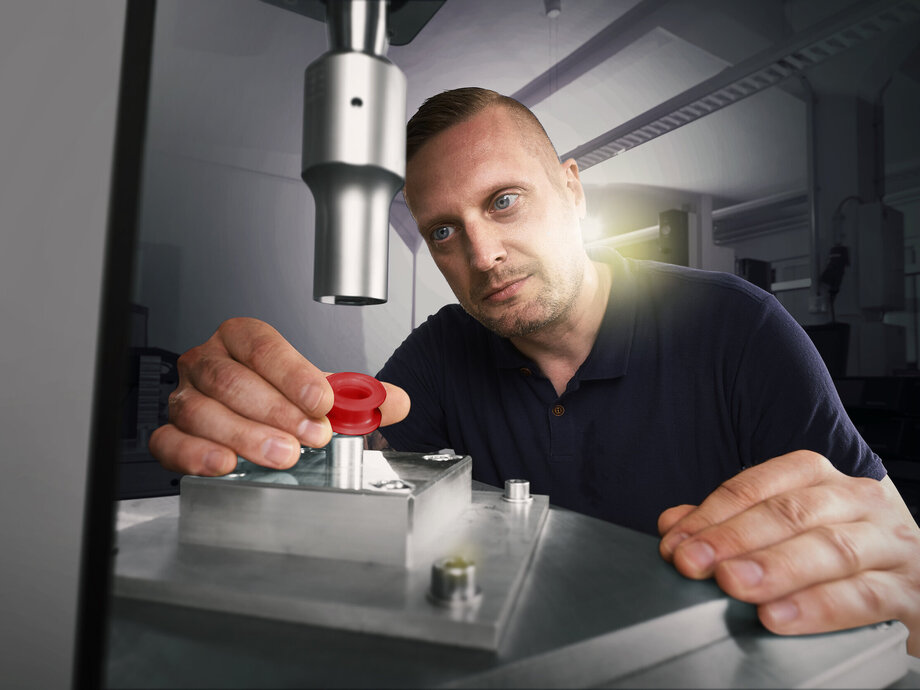

Process optimization

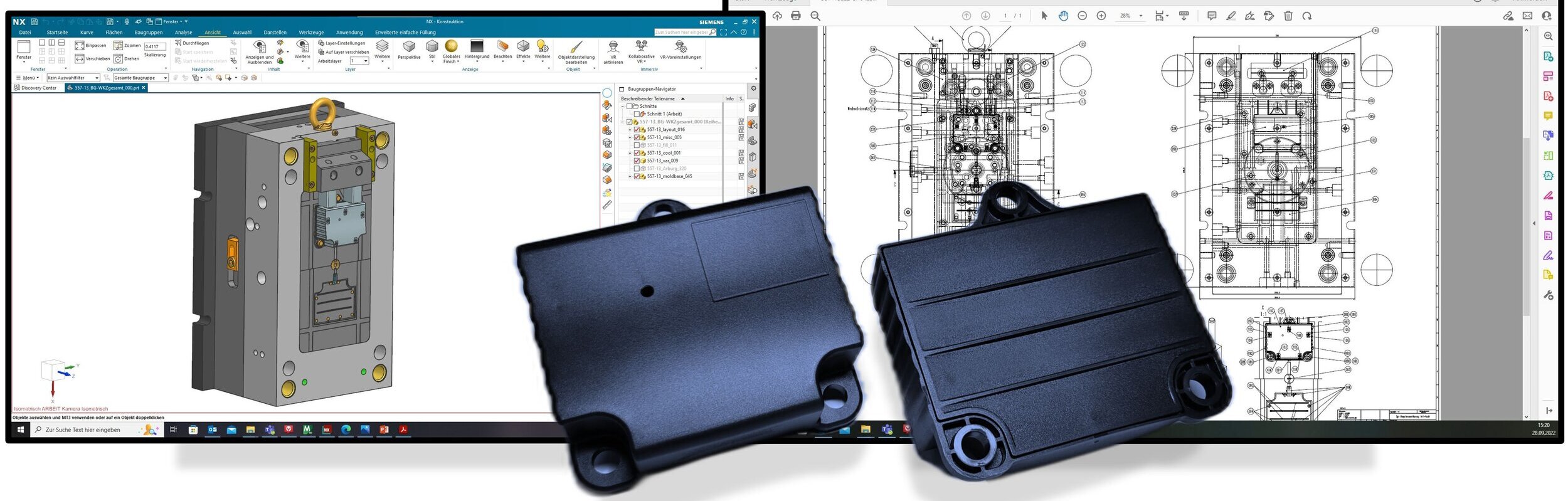

In the jungle of interactions between a wide variety of technical conditions and physical laws, it is not easy to maintain an overview.

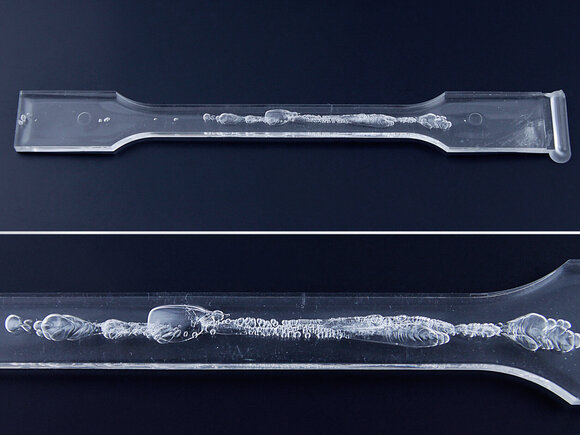

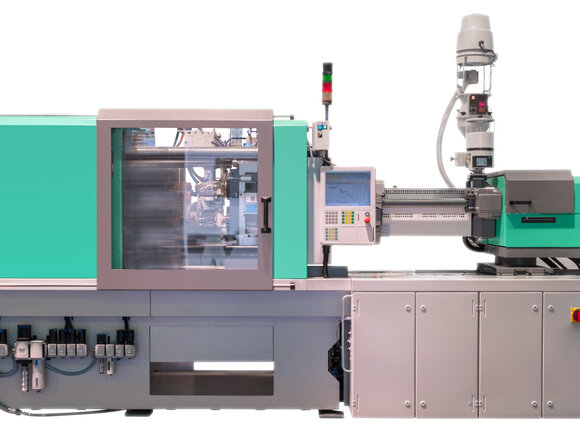

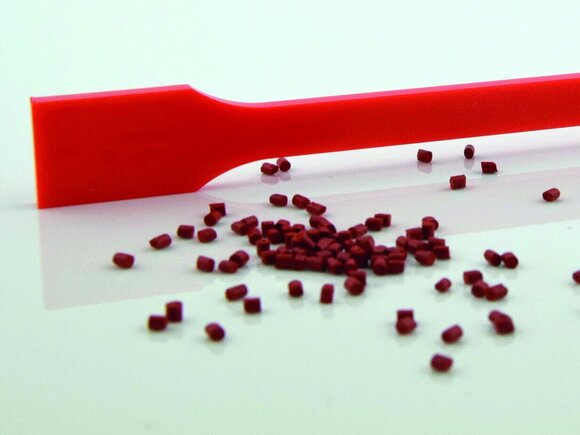

With a trained eye and appropriate measurement technology, we can examine your processes in injection molding and polyurethane processing as well as for plastic welding processes step by step, uncover potential for optimization in terms of quality, cost-effectiveness and sustainability, and avoid wasted costs. Don't be satisfied with your processes running stably! Save your resources and create scope for necessary new acquisitions or the further training of your employees.

"/>

"/>