Does your component actually hold on?

Mechanical tests

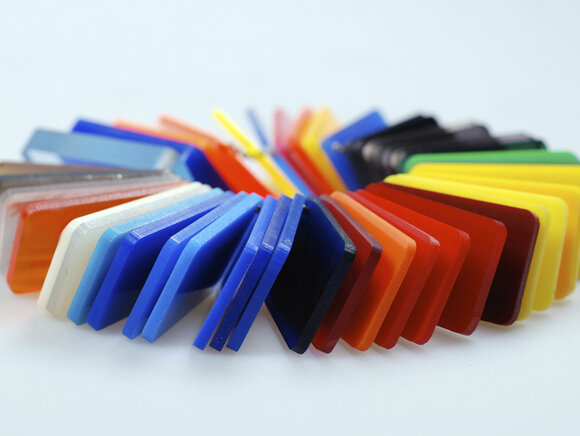

In component design, one starts with the stiffness and strength of the product. Therefore, mechanical properties are also an important part of plastics testing. Whether for the standard-compliant determination of characteristic values for component design, for the control of specifications and standards from automotive standards or for the comparative evaluation of different material batches, the full range of mechanical tests is often used here.

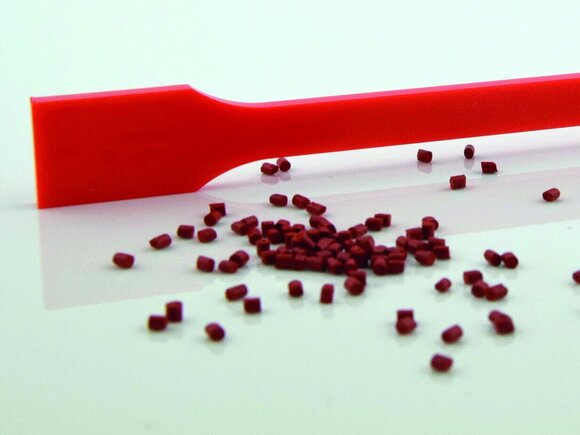

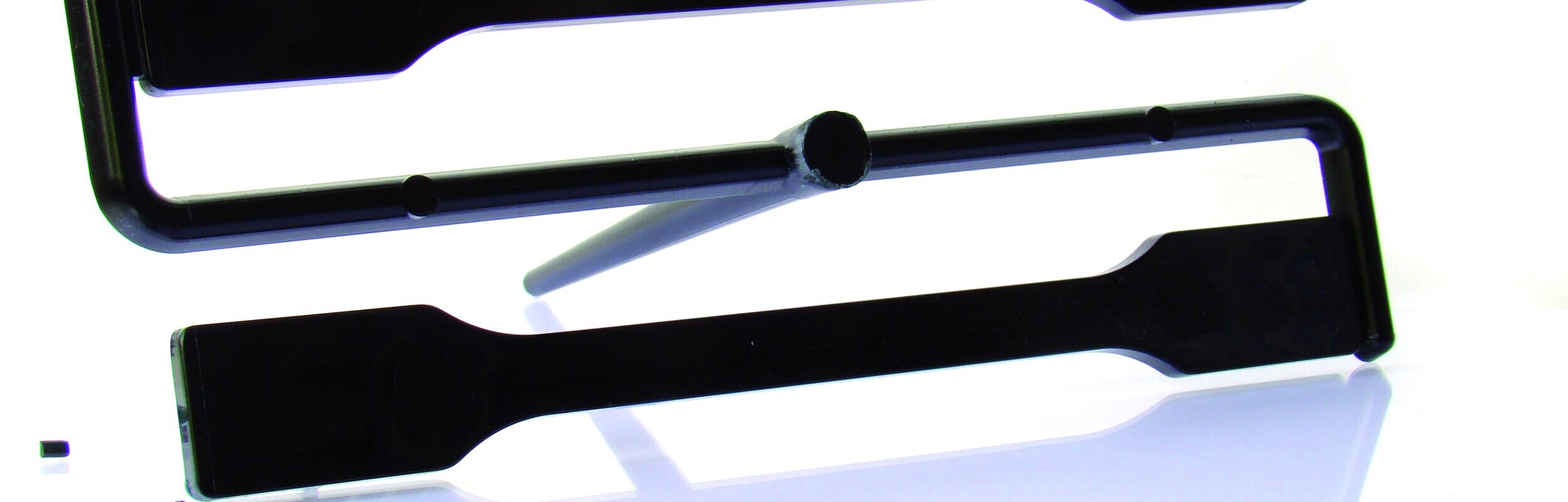

- Tensile test

Tensile testing is used when the tensile deformation behavior of specimens is to be investigated. Under defined conditions, the tensile strength, tensile modulus and other characteristic values can be determined in the tensile test to assess the stress-strain behavior of materials.

We offer the following possibilities of tensile testing:

- Tensile test on thermoplastics and elastomers

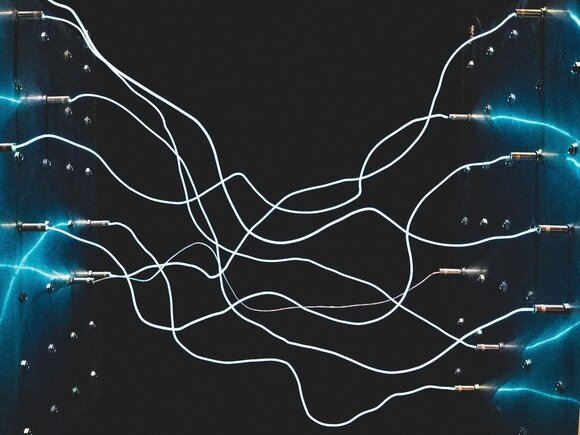

- Tensile shear tests

- Determination of maximum force/tear force

- Peel resistance on bonded joints

- Tear test on foils

- Bending test

The three-point bending test is the most widely used in the field of plastics testing. In this test, a test bar is placed on two supports under defined conditions and afterwards, a compressive load is applied to the center of the sample. This method is used to determine the flexural strength, the flexural modulus and other characteristic values for evaluating the behavior of a specimen under flexural load.

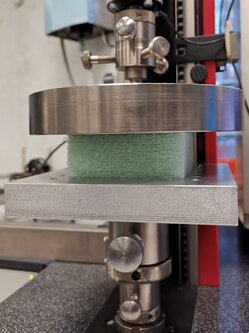

- Pressure test

The method is used for the evaluation of materials under compressive load to obtain information on the compressive stress-compression properties of a specimen under defined conditions.

We are offering you the following capabilities of compression testing in our accredited testing laboratory:

- Compression test on plastics (compact, foams)

- Determination of the maximum force

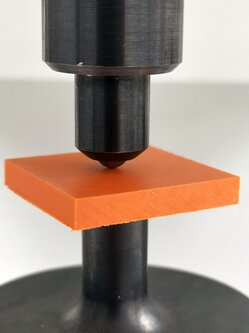

- Push-through tests

- Indentation hardness

- Compression hardness

- Impact testing

Impact and notched impact tests are used to evaluate the toughness behavior of plastics under impact loading. Notched or unnotched test specimens are used.

At the KUZ, impact and notched impact tests according to

- Charpy,

- Izod,

- Dynstat and

- in the impact tensile test

can be carried out.Pendulum hammers with working contents from 0.5 J to 50 J are available for the tests. This allows the characterization of both, brittle amorphous thermoplastics and tough materials such as UHMW-PE and composites. With the help of the integrated cryochamber, the experiments can also be performed at temperatures between room temperature and -70 °C.

- Hardness test

The hardness of a material is defined as its resistance to penetration by a body. In the field of hardness testing, there are different procedures depending on the material and application objective of a sample.

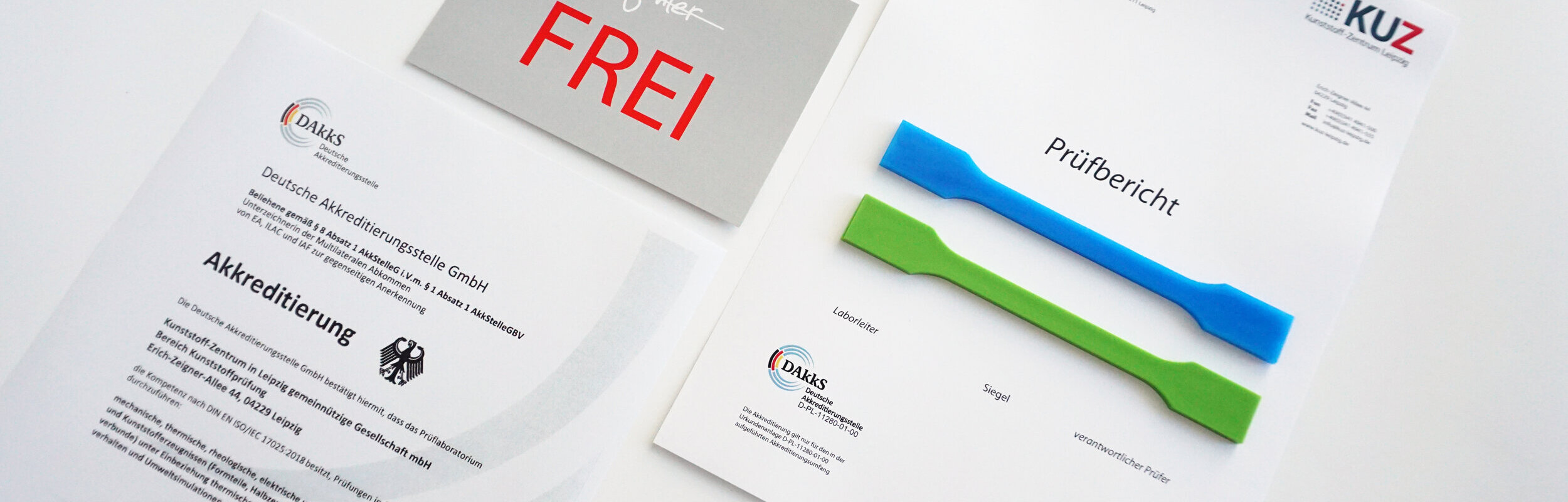

We offer the following hardness tests in our accredited testing laboratory:

- IRHD (micro hardness testing)

- Hardness testing according to Shore A

- Hardness test according to Shore D

- Ball indentation hardness

Our services for mechanical testing in detail

Our equipment at a glance

Type Z020 with temperature chamber

Universal testing machine

Zwick GmbH & Co. KG

Type 2.5 kN with optical strain gauge

Universal testing machine zwicki

Zwick GmbH & Co. KG

CEAST 9050

CEAST 9050 pendulum impact tester

Instron GmbH

Ball indentation, Shore A/D

Hardness testers

Bareiss, Kögel

"/>

"/>