Solution-oriented assistance

Consulting

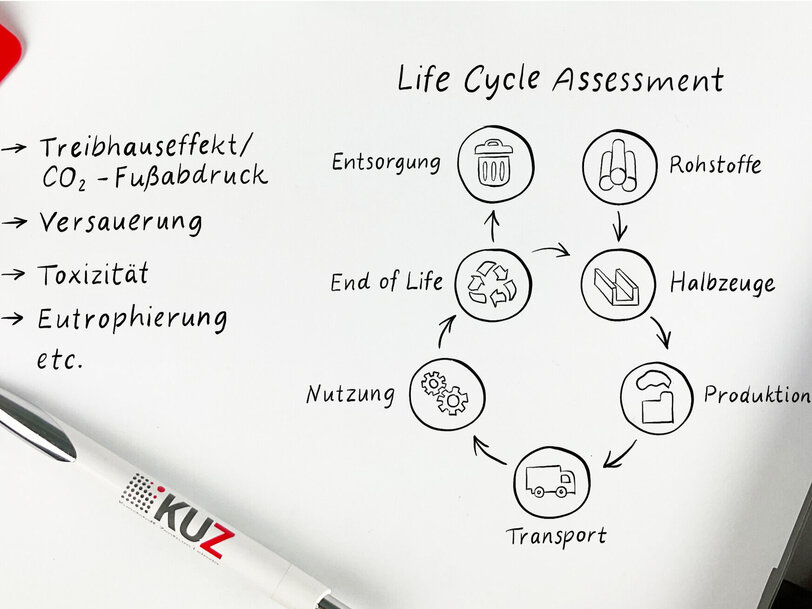

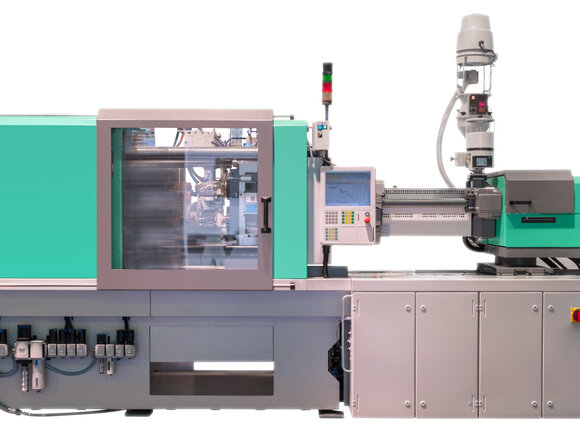

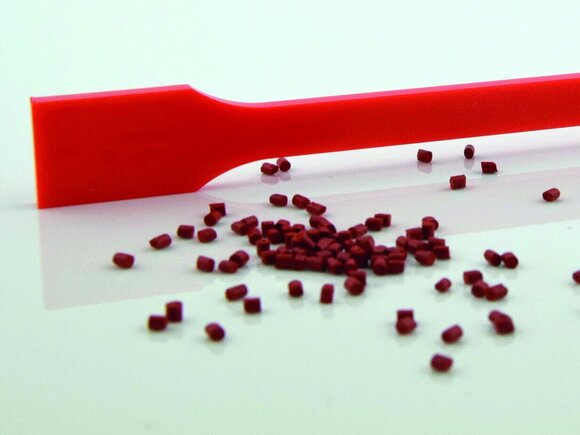

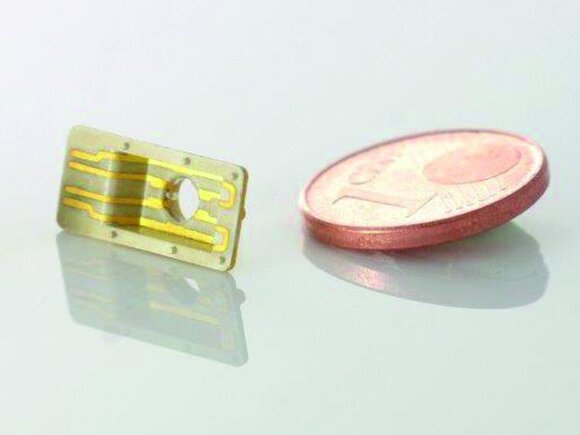

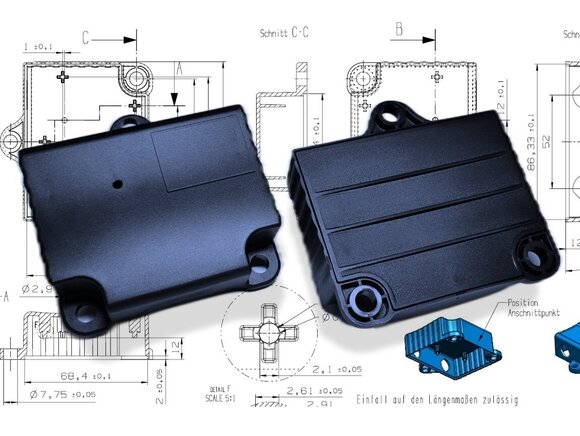

In close cooperation with our specialist engineers, you can discuss your problems relating to plastics / plastics technology and jointly develop solution concepts. We support you on-site and also online to analyze your processes and derive target-oriented action plans. Our core competencies include topics such as material research, new material development, molded part & tool development as well as suitable manufacturing processes or concrete optimization approaches for existing processes (cycle time, quality, energy, sustainability optimization).

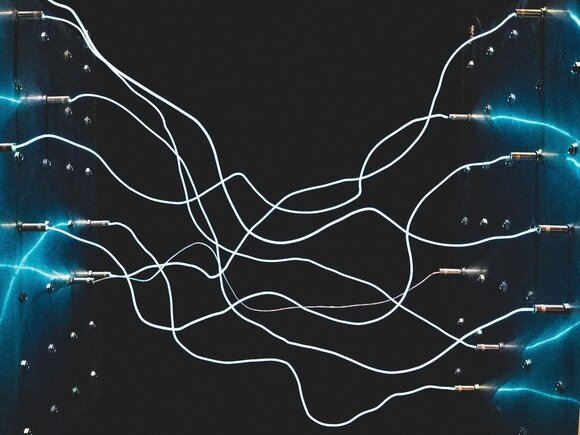

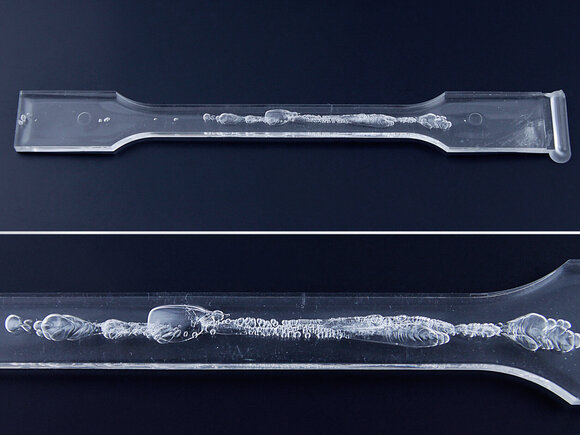

Our tips and advice on troubleshooting are particularly in demand. Due to the increasing complexity of plastic molded parts and processing, error patterns and damage analyses are also becoming more demanding and require our combined knowledge and experience in the areas of processing, mold design and plastic testing. Further questions about suitable joining and bonding methods for your plastic molded parts will also not go unanswered. You can rely on the independent advice of our welding and joining specialists.

Our teams can also advise you on applying for and carrying out subsidized projects. Do not hesitate to contact us if technical and technological issues also involve the implementation of new trend topics in your company. Through our market-oriented research in topics such as recycling, lightweight construction or digitization, we have access to the right partners, know-how and great ambition to transfer these trends into practical application with you.

"/>

"/>