Plastic innovatively shaped

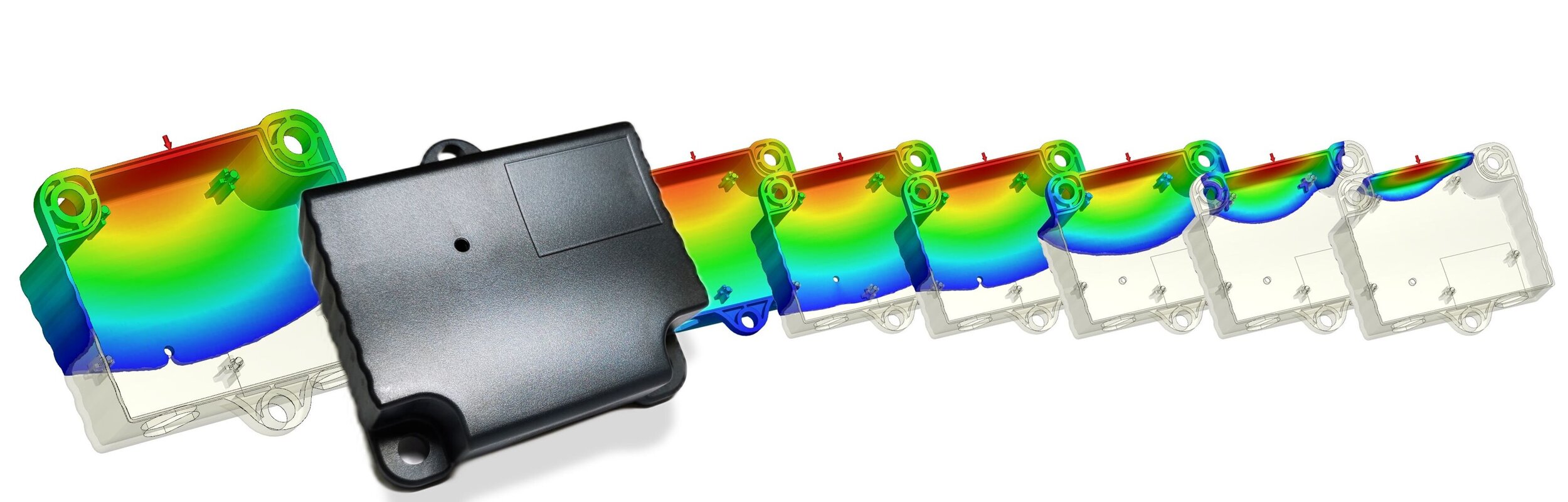

Injection molding

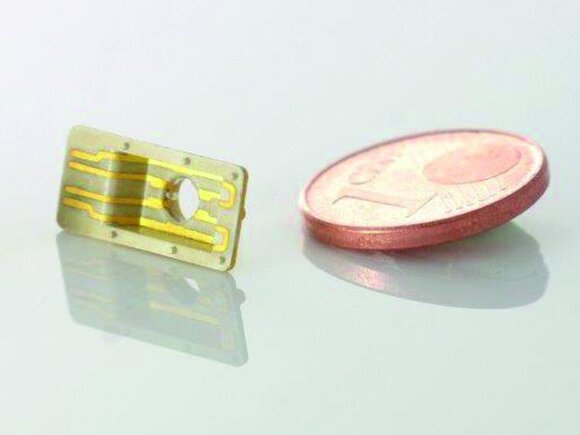

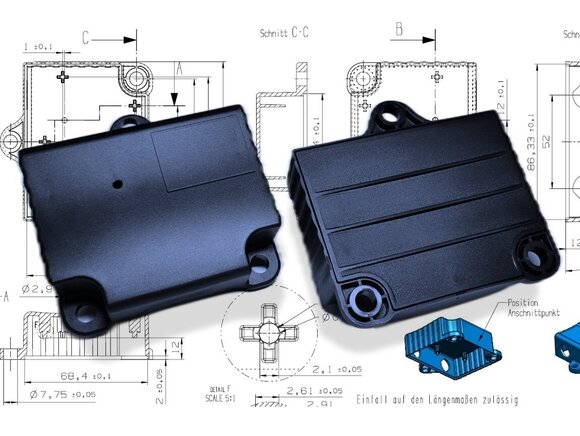

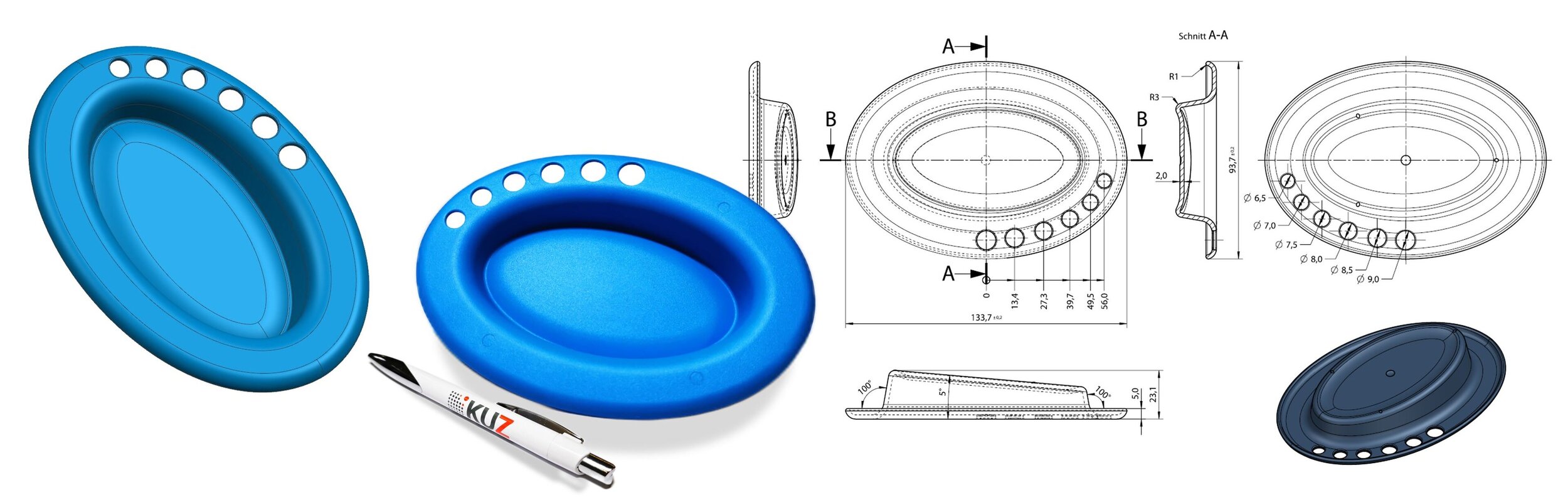

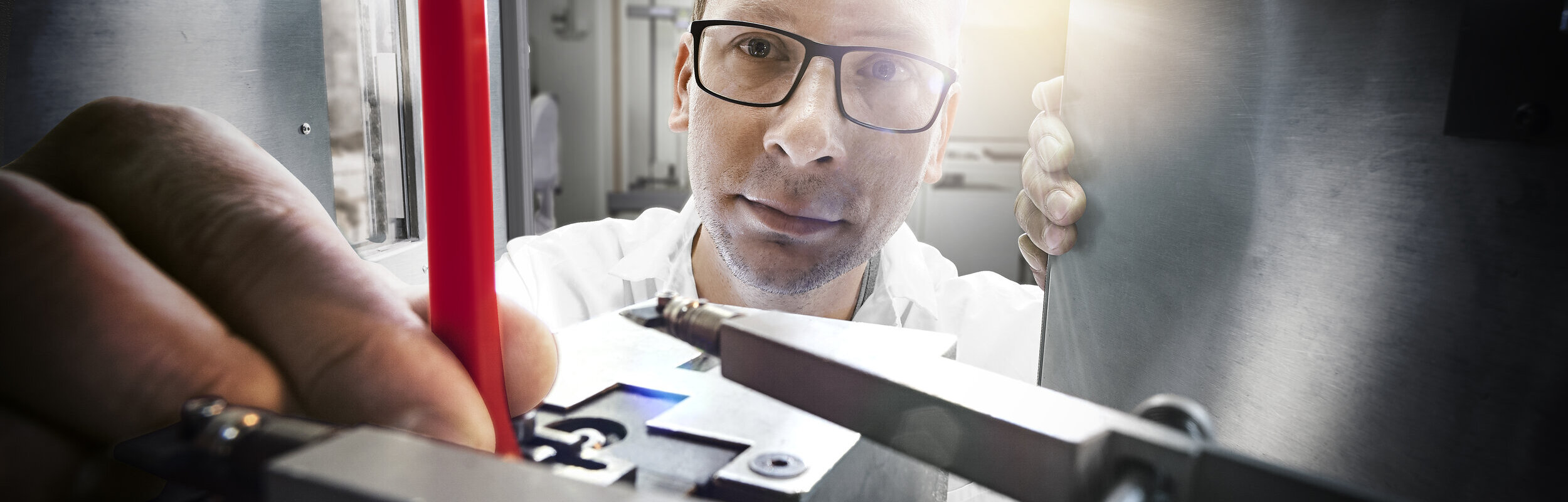

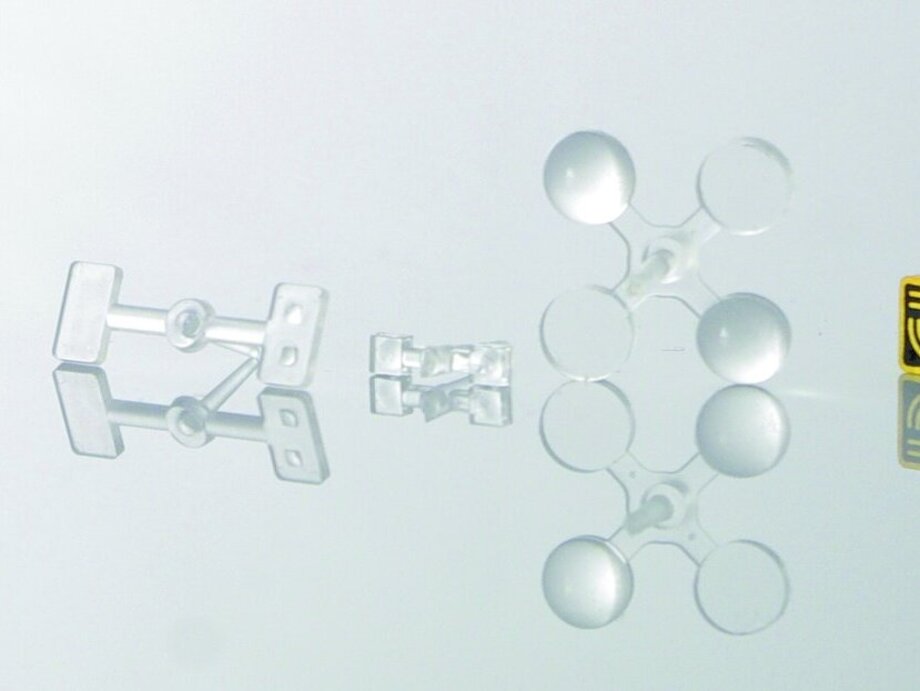

In addition to other major plastics processing methods, injection molding is one of the most frequently used primary molding processes. The range of molded parts that are produced fully automatically and cost-effectively by injection molding extends from simple mass products to complex, technical components and assemblies. Within this spectrum, we can also support you with targeted preliminary tests based on a wide variety of test and specimen samples.

Our injection molding services in detail

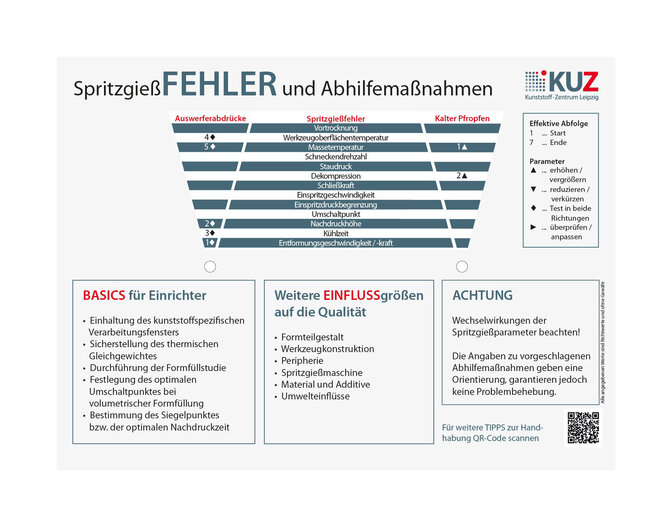

Online defect catalog

Spritzgiessfehler.de - is the online defect catalog of the Kunststoff-Zentrum in Leipzig (KUZ). This tool gives you quick access to clearly structured information on the subject of injection molding defects. Defects can be displayed directly, but can also be sorted from different perspectives, such as that of the molding developer, the material manufacturer or the mold designer. With free access, you benefit from our experience and knowledge of defect prevention and scrap minimization. You can look forward to the extension of the defect images at regular intervals.

To the Online Defect catalog (for now only in german)

Already listed are for example:

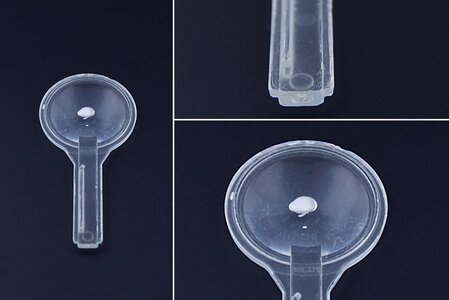

- Blowhole

What to do if the molded part weight fluctuates?

Possible cause: e.g. shrinkage cavities due to insufficient shrinkage compensation.

Elimination measures:

- Increase of holding pressure

- Extending the holding pressure time

- Avoidance of large wall thickness jumps as well as mass accumulation

- Checking and, if necessary, enlarging the nozzle bore, the gate and gate cross-section

- Checking and, if necessary, changing the gating position

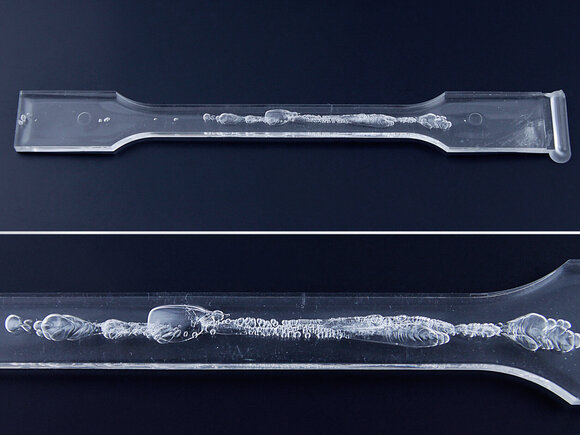

- Barrette

What to do if weld lines appear on injection molded parts?

Possible cause: e.g. melt temperature too low.

Remedial measures:

- Increase the melt temperature

- Increase of mold temperature

- Adjustment of injection speed, etc.

- Delay

What to do if warpage occurs on the molded part?

Possible cause: e .g. holding pressure effectiveness too low.

Remedial measures:

- Improvement of the holding pressure phase

- Adaptation of the cooling phase

- Optimization of the injection speed, etc.

Injection Molding Guide

The Injection Molding Guide is a handy, compact tool for processors in A5 format with two rotating selection wheels, similar to a parking meter. Easy to use, the tool can be used to determine material-specific processing parameters or provide assistance for injection molding troubleshooting. On the front side, 24 different material data of common as well as special plastics such as COC or PEEK are listed and on the back side, 24 injection molding errors are additionally listed, which offer the processor assistance for the injection molding error correction.

Learn more (for now only in german)

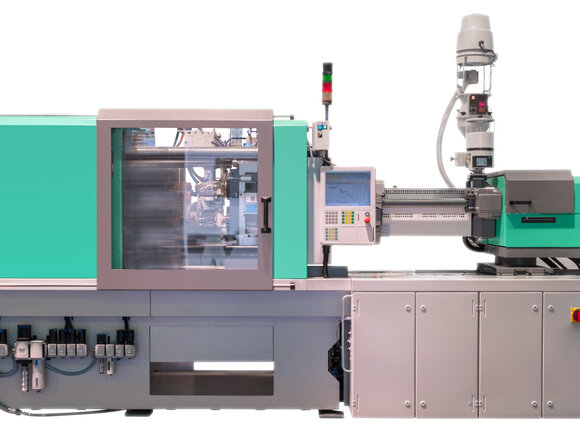

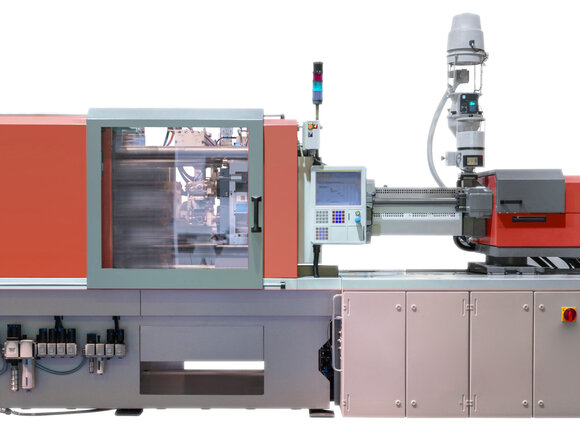

Our machine equipment at a glance

Injection molding machine

Allrounder 370 E 600-170

Arburg

2K Injection molding machine

Victory 330H 80V / 80

ENGEL

Injection molding machine

ergotech 100/420-310s

Sumitomo (SHI) Demag

Injection molding machine

IntElect 100/470-180 smart

Sumitomo (SHI) Demag

2K Injection molding machine

HM-MK 180/750H/350V

Wittmann-Battenfeld

Injection Molding Machine - AI Test Bench

IntElect2 50 370-110

Sumitomo (SHI) Demag

"/>

"/>