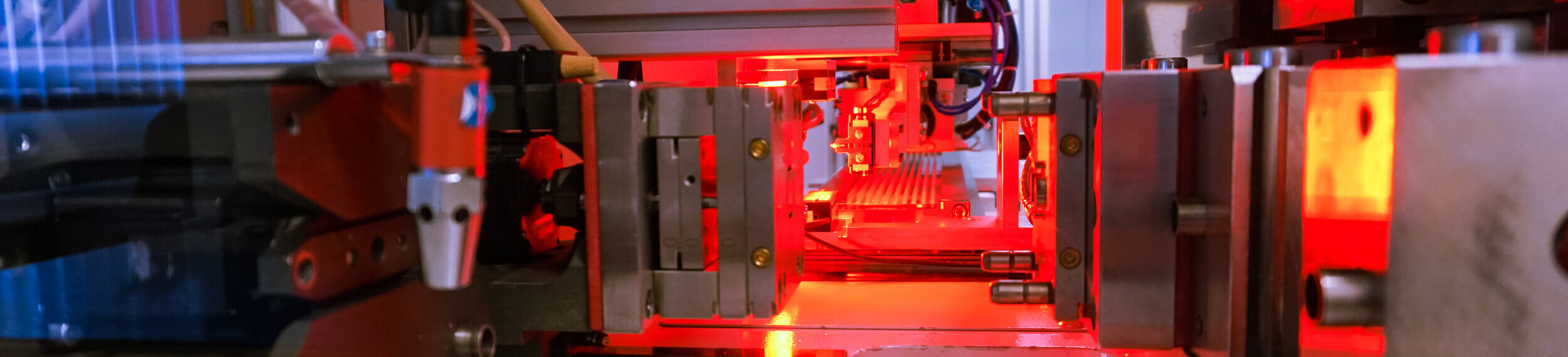

Plastic efficiently molded into the product

Process development

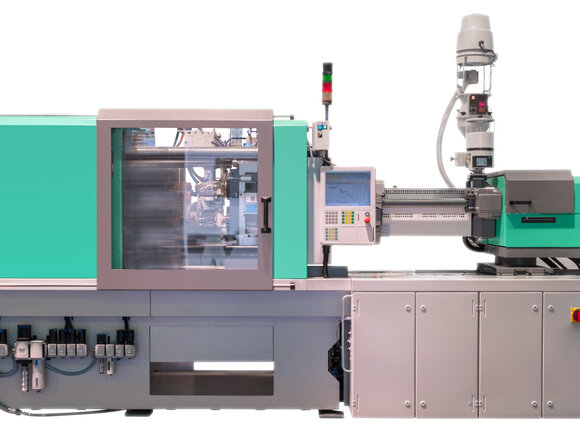

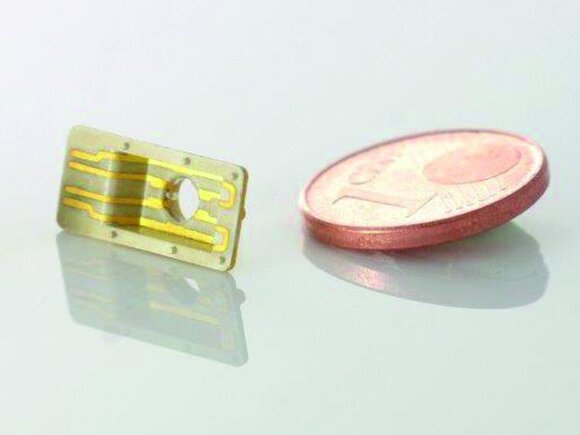

Molded part design and application requirements for the molded part are defined. We support you in finding the suitable manufacturing process depending on the batch sizes. This is followed by the fine-tuning with regard to the design suitable for the plastic and the process. Using the synergies between our designers and engineers from processing and joining technology and material development, we help you with process and technology development. We explore the possibilities of process combinations in interaction with hybrid material systems and create the basis for your project-related decision. This approach guarantees a fast implementation of your product ideas into real processes for the efficient and sustainable production of innovative plastic products.

Take advantage of our comprehensive know-how for process and technology development.

We offer you the following services for this purpose:

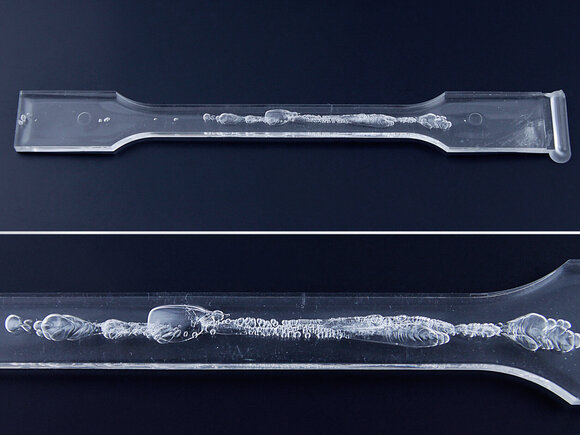

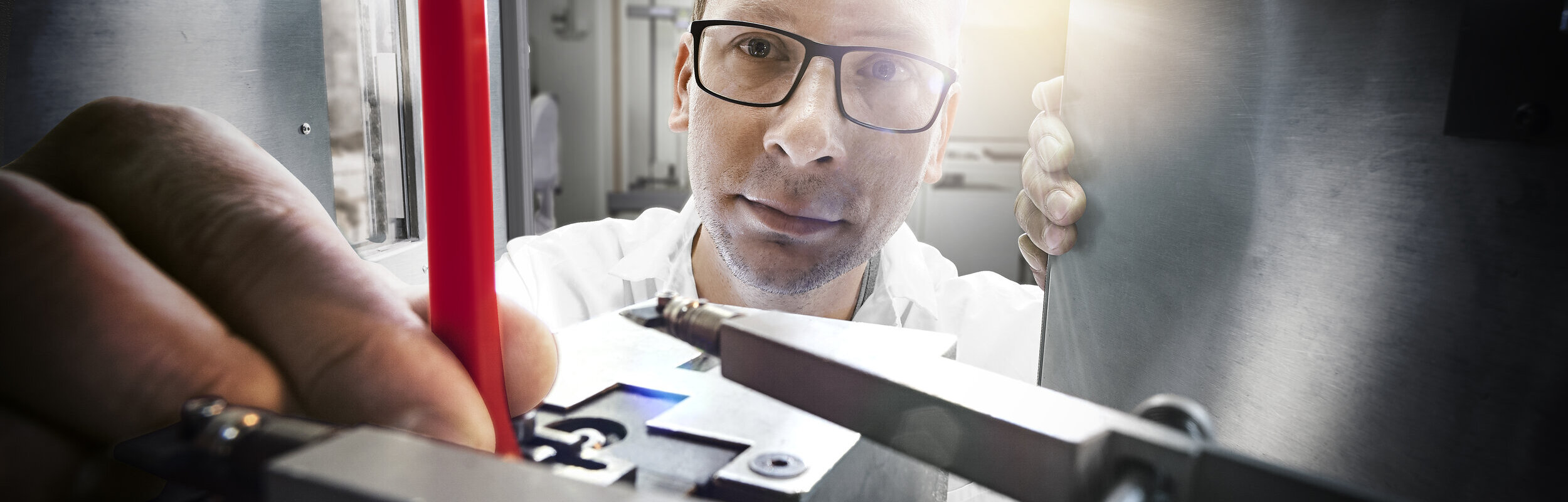

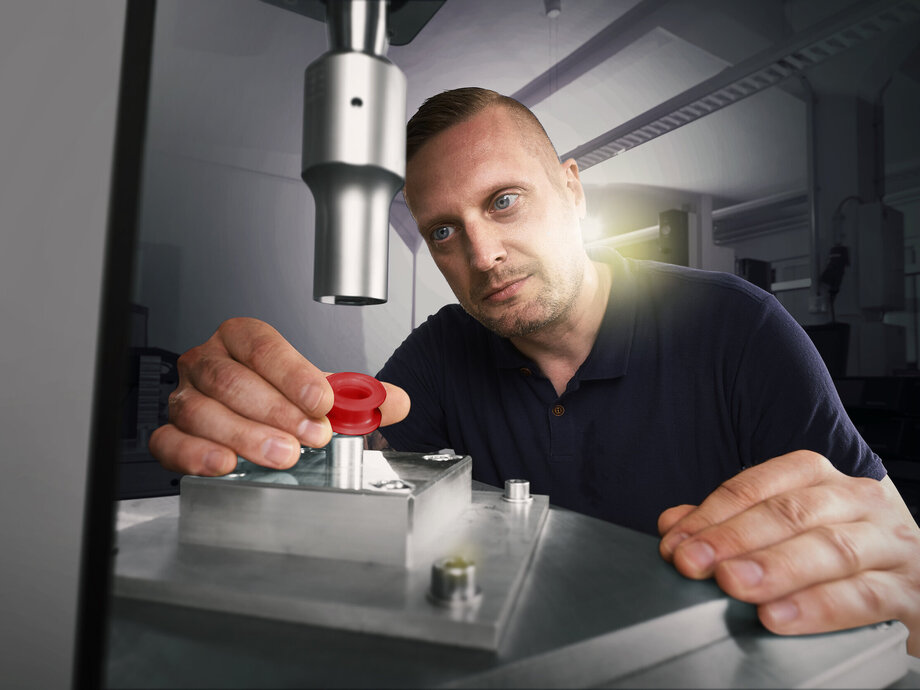

- Feasibility analyses and preliminary tests

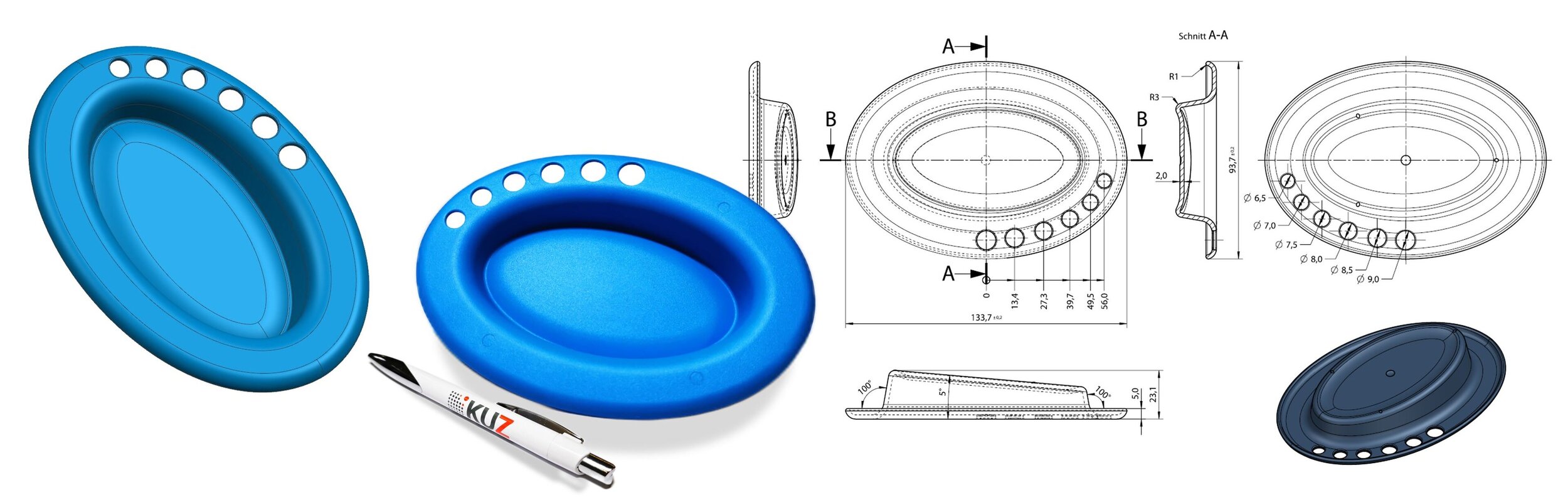

- Plastic and process-compatible design

- Plastic and process-compatible mold part tolerancing according to DIN 16742 / ISO 20457

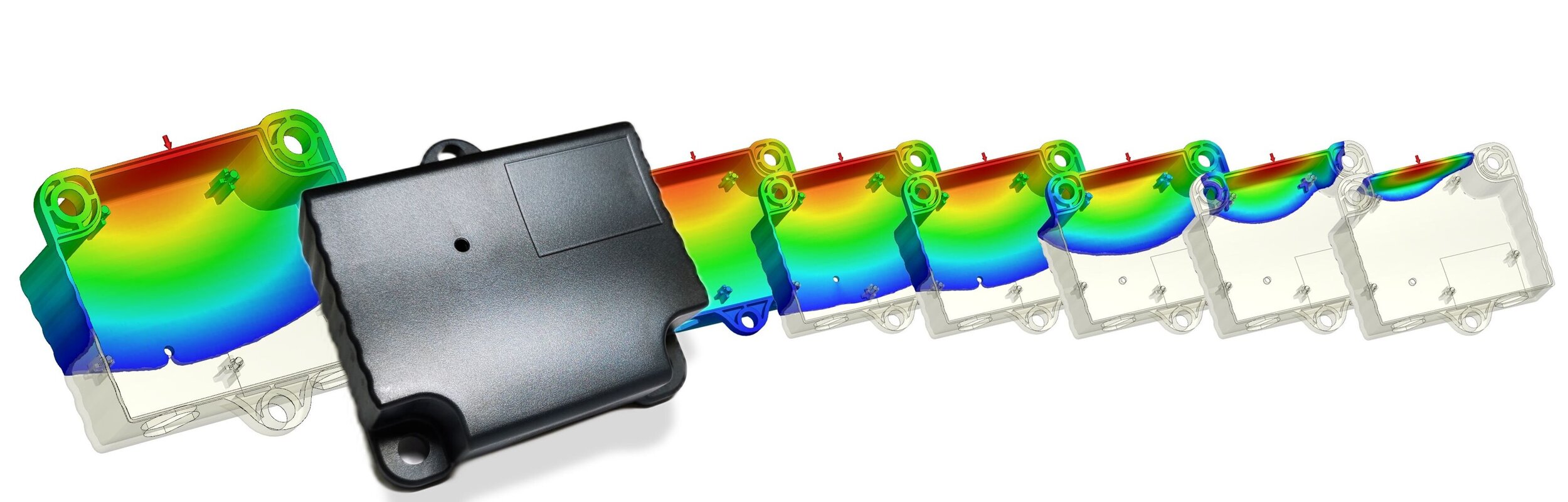

- Development of manufacturing concepts, process and procedure selection

- Derivation of automation approaches

- Welding design of series parts

- Simulation of joining processes

- Fixture construction and plant development

"/>

"/>