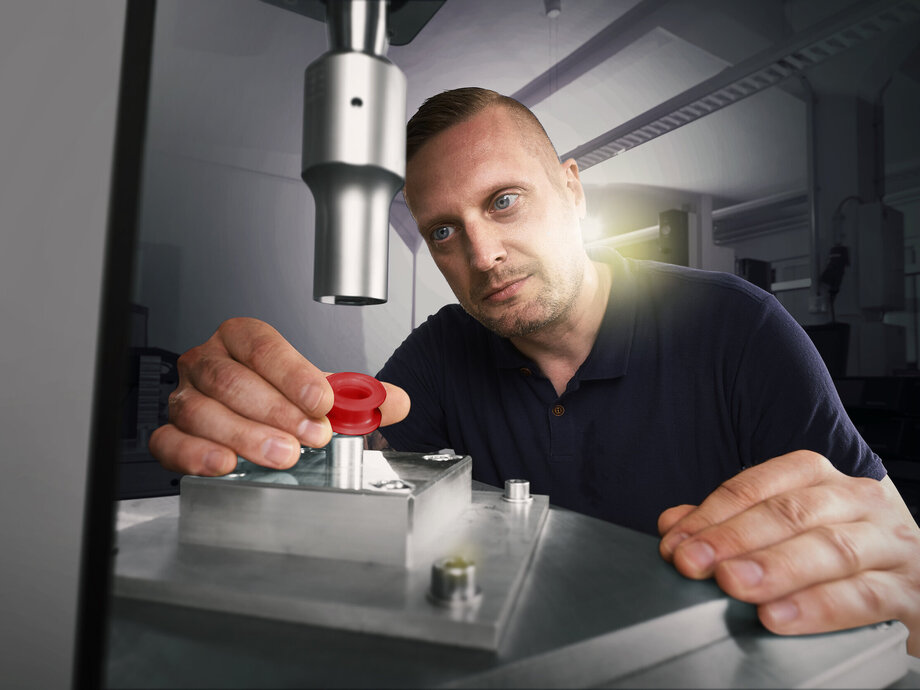

Give your ideas the right shape

Tool development

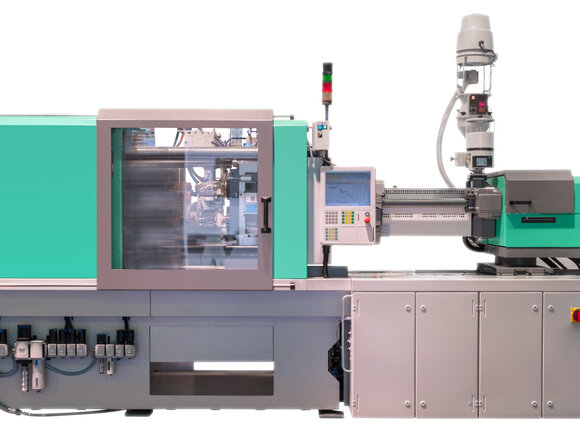

Do you want your plastic design for injection molding to be reproducible and produced in high quality in series?

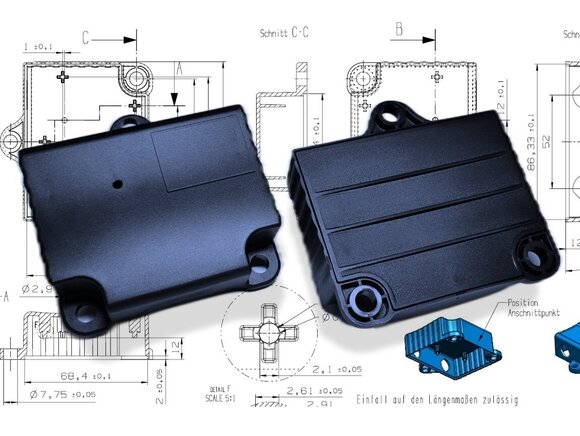

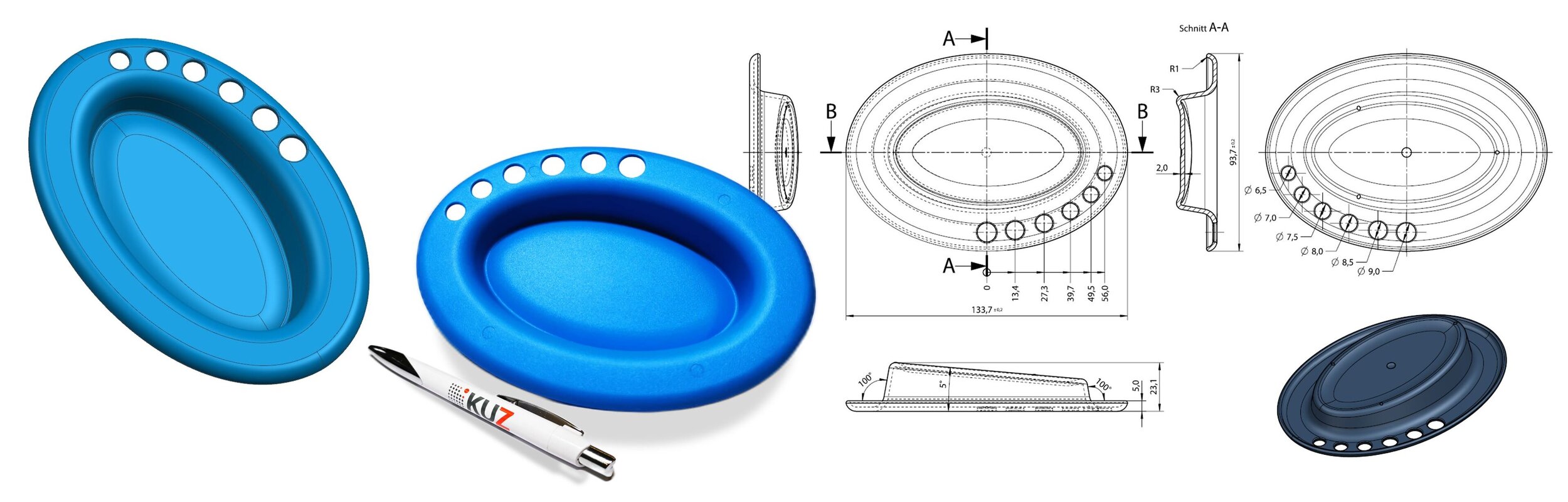

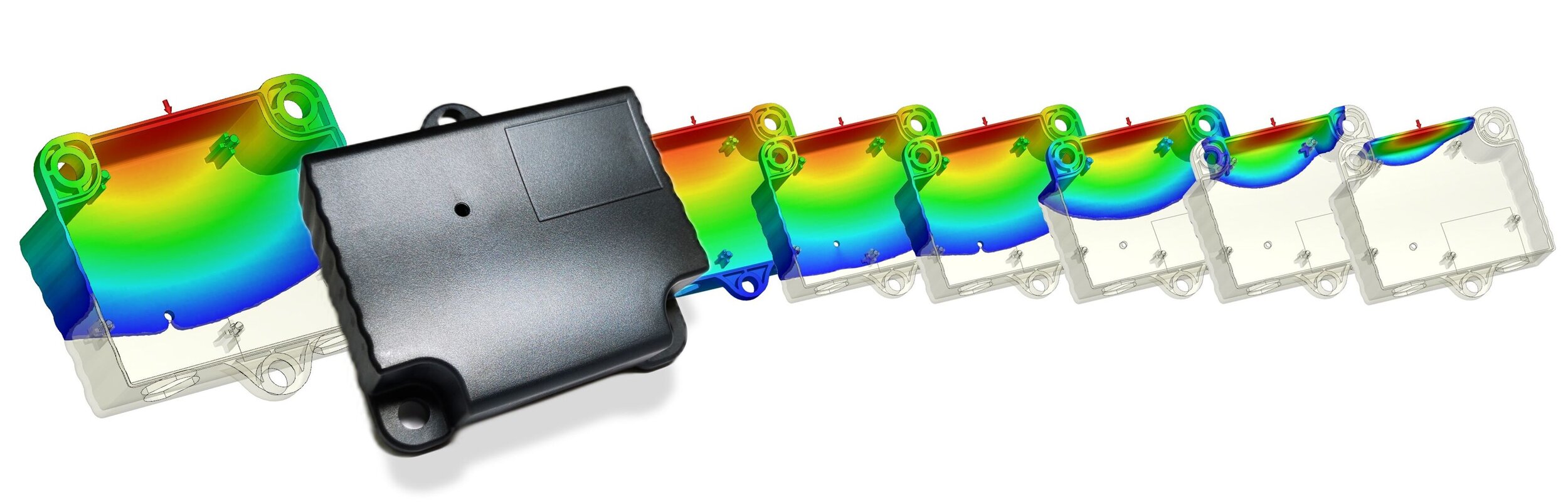

Then you need an injection molding tool that reliably fulfills all requirements from molding and technological process control. We support you from the conception and design of the tool through 3D design to tool construction. For this purpose, we have modern CAD and simulation software at our disposal, which enables us to work in a virtual development environment. This approach guarantees you an efficient and sustainable tool design.

Take advantage of our know-how in tool design

We offer you the following services:

- Feasibility analyses

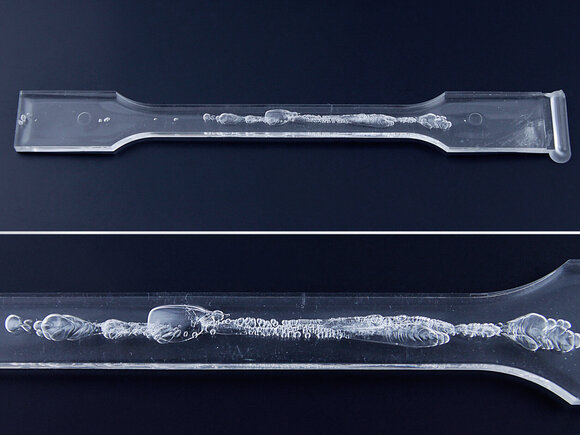

- Sprue design

- Mold design

- Rheological mold design

- Thermal mold design

- mold design

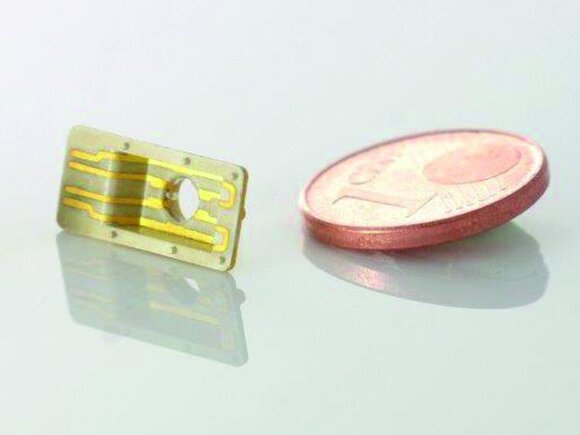

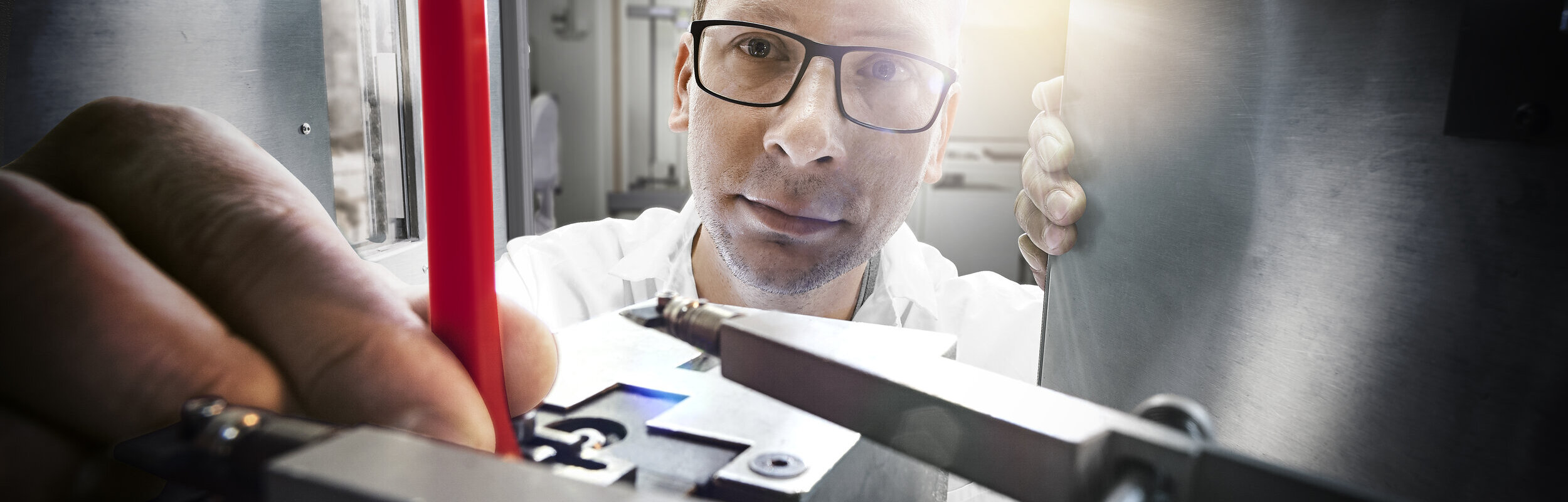

- experimental toolmaking

- tool production

- Functional sampling

- pilot production

"/>

"/>