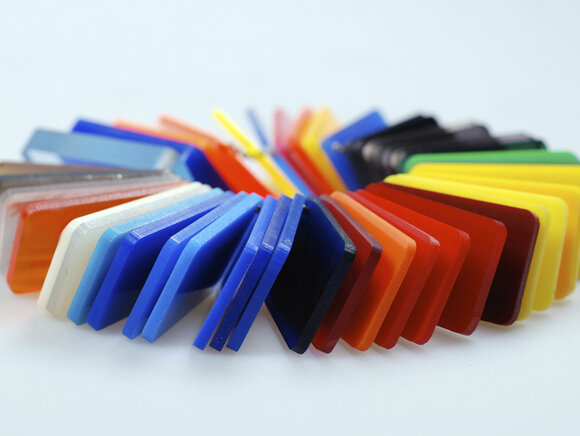

Plastic and its glossy properties

Surface testing

The appearance of a surface determines the visual impression of a product and should convey a feeling of value and quality to the viewer. The look and feel of a surface should also last as long as possible in use. Surface tests simulate the resistance of surfaces to different influences such as scratching, rubbing or various media (hand perspiration, sunscreen, cleaning agents, ...). Depending on the load, possible damage can thus be identified in advance and thus avoided. The assessment of the visual impression, as well as the color and gloss measurement are also part of the surface inspection.

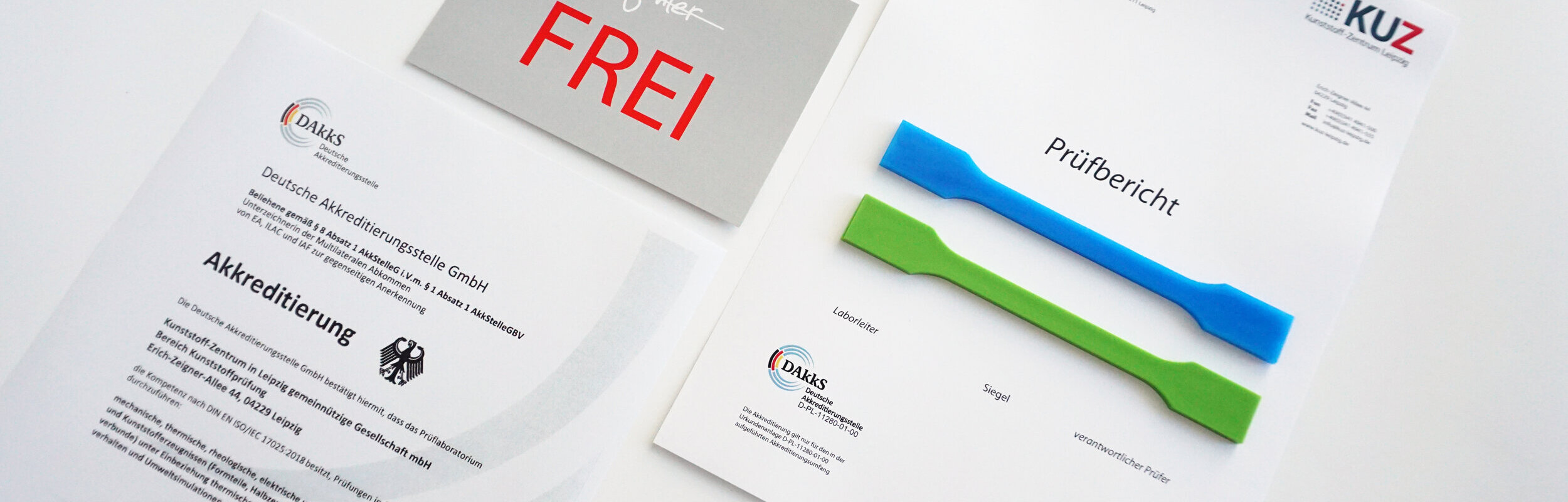

- Visual assessment

The color of a plastic part can vary depending on the ambient light. To avoid such so-called metamerism effects, a visual assessment of the part is often mandatory. This is always carried out by trained personnel in a color matching booth. Visual assessment using a gray scale is used to evaluate optical changes to a surface as a result of climate storage.

- Color and gloss measurement

To determine the color impression of a product, measurement technology can be used in addition to the human eye. This enables the evaluation of a color by means of color values and not only on the basis of verbal descriptions.

Color measurement is commonly used in the following application areas:

- for the description of color differences between two samples (original and post coloration)

- chemical or physical influences on colored products

- as a basis for color tolerances between customer and supplier

In addition to color, the gloss of the surface also plays a major role in the visual impression of a product. Here, the appropriate measurement technology enables gloss measurements from high-gloss to matt surfaces.

- Abrasion and scratch resistance

In automobiles, a large proportion of the interior surfaces are now made of plastics. To ensure that these surfaces look as high quality as possible for as long as possible, they must have a high resistance to hand perspiration, various media (cleaning agents, sunscreen, hand cream, ...) and textiles. To simulate such stresses, abrasion and scratch resistance tests are performed. In these tests, a dry fabric or a fabric mixed with a medium is moved over the sample surface at a defined speed and pressure. The change in the surface is then assessed visually. Prints on operating elements are also tested in this way for their abrasion resistance (= rub resistance).

- Media resistance

Many plastics have to withstand the influence of sometimes aggressive liquids such as fuels, cleaning agents, cosmetics, coolants and lubricants. Often, this stress occurs in conjunction with high temperature fluctuations. Exposure to media can lead to restrictions in the material properties of plastic parts, such as swelling, softening or the formation of stress cracks. Depending on the product's area of application, the material should have good resistance to certain media. The media resistance can also be tested under the influence of temperature or mechanical stress.

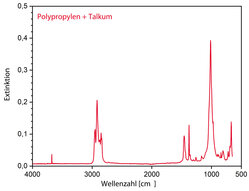

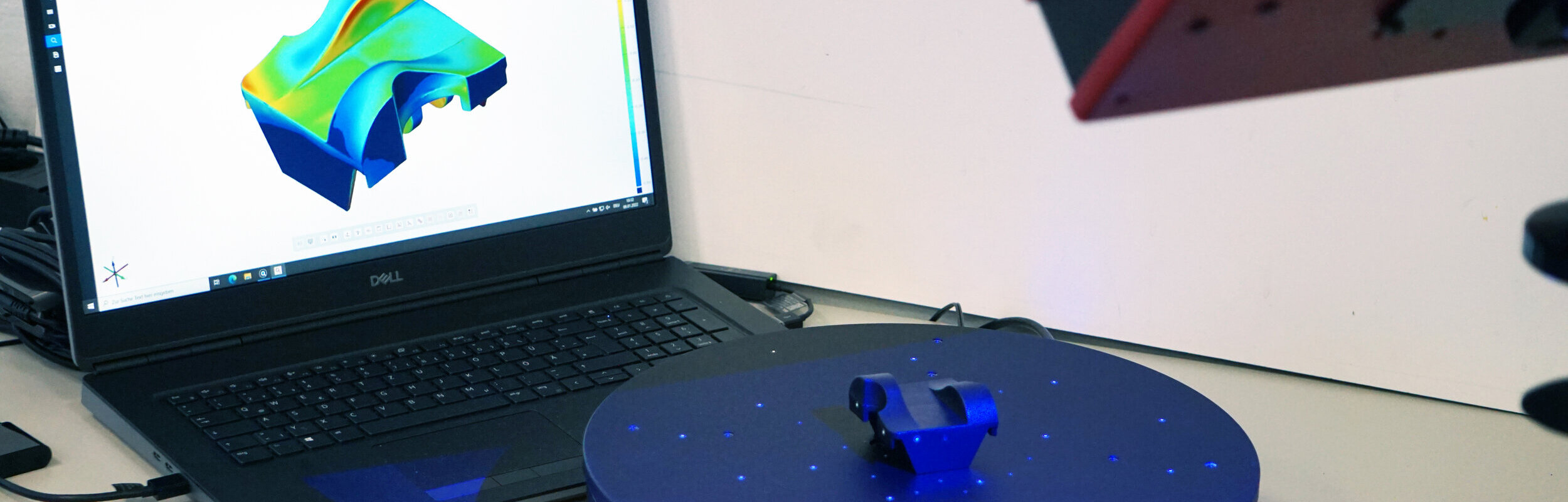

- Infrared spectroscopy (IR)

Infrared (IR) spectroscopy is a test method for identifying chemical groups on the surface of a component, enabling the (mostly) non-destructive identification of plastic materials. In this method, light of a defined wavelength is passed through a sample via an interferometer. The chemical groups contained (e.g. methyl/carbonyl/amide/aldehyde/ester group) absorb the energy of specific wavelengths. Since this is specific to each group, it allows identification of plastic types based on their basic chemical structure. Solid samples can be measured in reflection using an ATR attachment.

IR spectroscopy also allows the identification of foreign material in a component, and therefore, the method is often used to detect damage. For example, aging processes can also be tracked by evaluating the carbonyl band. In many cases, this can be supplemented by an additional DSC measurement.

Our surface testing services in detail

Our equipment at a glance

LED Color Viewing Light XL Hybrid Basic

Color sampling booth

Just Normlicht GmbH

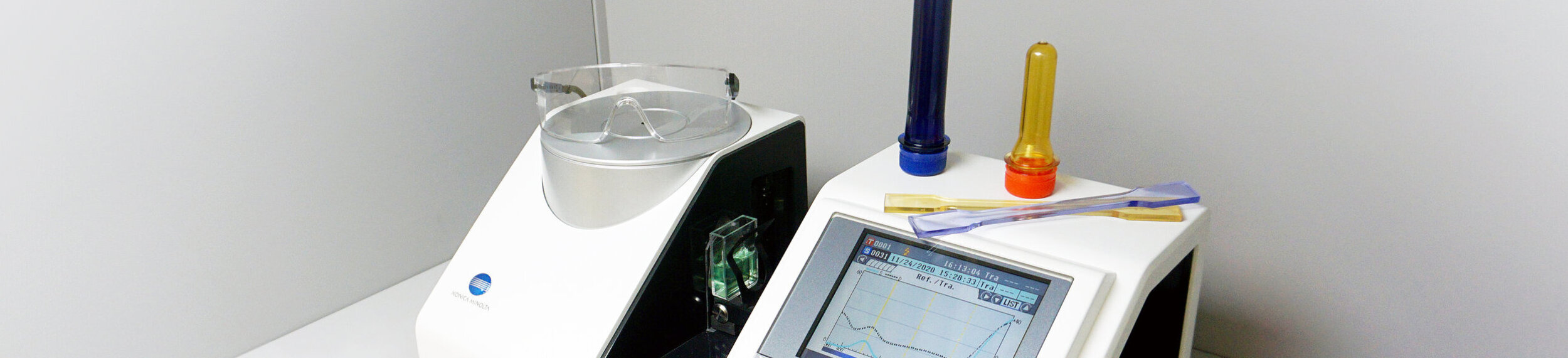

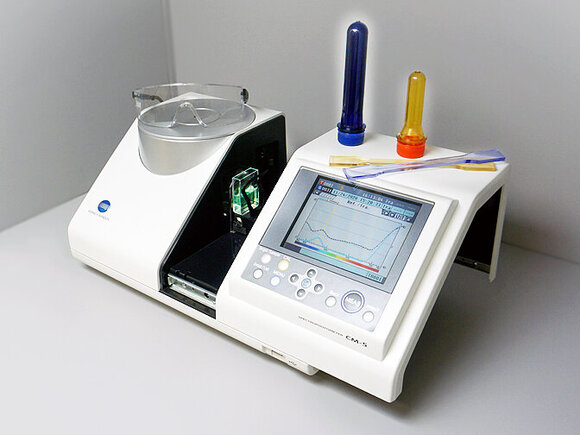

Spectrophotometer CM-2600d, CM-25c G, CM 5

Colorimeters

Konica Minolta

IQ-S

Glossmeter

Rhopoint

Model 435

Wear resistance tester

Erichsen GmbH & Co. KG

Model 463

Scribe according to Sikkens

Erichsen GmbH & Co. KG

Model 295

Multi Cross Cutter

Erichsen GmbH & Co. KG

Model CM1

A.A.T.C.C. Crockmeter

Atlas MTT GmbH

Abrex

Hand abrasion

Innoweb GmbH

Dynaspa

Scratch and friction tests

Innoweb GmbH

Nicolet iS10 (Diamond ATR, Germanium ATR, Transmission)

FTIR spectrometer

ThermoFischer Scientific

"/>

"/>