KUZ at KUTENO: Focus on material development and recycling

Engineering plastics, biopolymers & upcycling

The speed at which new materials come onto the market to adapt to trends and customer requirements is constantly increasing. To ensure that processors remain flexible and can actively respond to changing requirements, the KUZ offers the modification of existing plastics with appropriate additives. Effective tools are provided for the step-by-step development of formulations. Typically, the first step begins with extensive series trials in small quantities, for which a torque and extrusion rheometer is available. Larger quantities for industrial production trials are produced by twin-screw extrusion. Subsequent processing into test specimens or molded parts enables their qualitative evaluation. In this way, both processing and component properties can be optimized.

At the KUZ stand, visitors can obtain advice on the topics of material development and upcycling of a wide range of different types of plastic. The focus here is on the development of innovative, sustainable materials. As an exemplary exhibit, the KUZ will be showing a biobased type of plastic made from waste materials from grain and forestry processing. This is completely biodegradable and therefore predestined for disposable products.

The processing and property optimization of recycled material is shown as an example for 3D printing. Here, the quality level of virgin material can be achieved by adding the appropriate additives to the print waste. The complete process cycle can be mapped here: from incoming goods inspection of the print waste, through material shredding and preparation, to test piece injection molding, printing and testing. The recycled material is suitable for pellet printing and can also be used to extrude filaments for fused deposition modeling (FDM) printing.

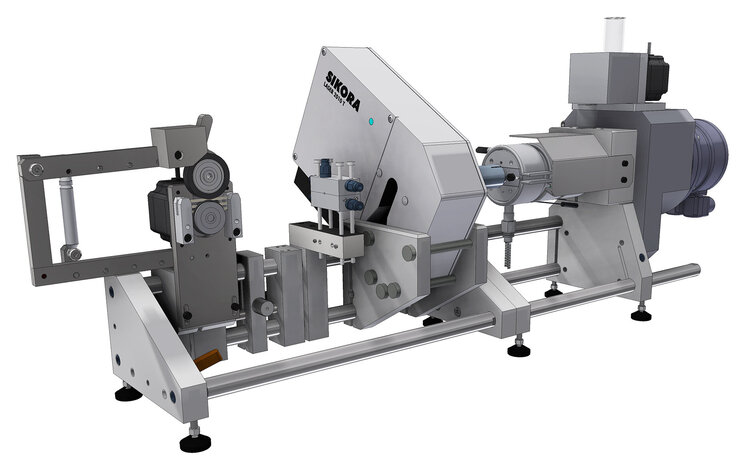

Flexible compact extruder - small. fast. versatile.

In microtechnology and for the material development of small batches, extruders are required in both continuous and discontinuous operation, which provide small amounts of melt in an optimally homogenized thermal and material state. The newly developed dwell time-optimized and largely rigid compact extruder will be exhibited at the KUZ stand. It serves as the basis for various plastics processing machines in microtechnology. For example, as a small-volume extruder for micro profile extrusion and for multi-component extrusion or as a high-performance 3D print head. Another proven application is its use as a pre-plasticizing unit for micro injection moulding.

KUZ competition on trade fair topics

A visit to the KUZ trade fair stand is worthwhile in more ways than one. In addition to exciting exhibits, tech talk & personal exchange of experiences, there is a special highlight for visitors this year. In the knowledge quiz about our exhibits, you can win a voucher for a one-day seminar at the KUZ. Here, knowledge on a selected topic can be deepened and taken to a new level.

The KUZ at the KUTENO

Exhibition stand: Foyer / EN10

exhibitor page

Registration for free ticket