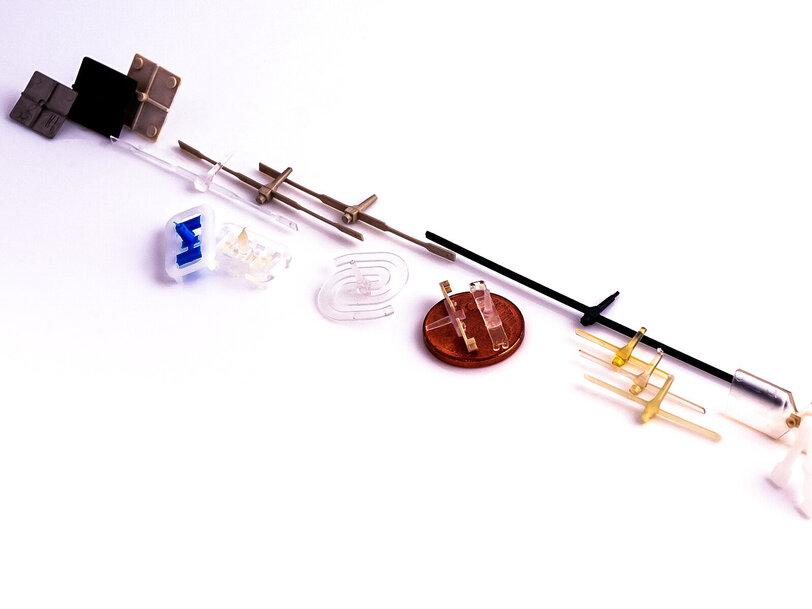

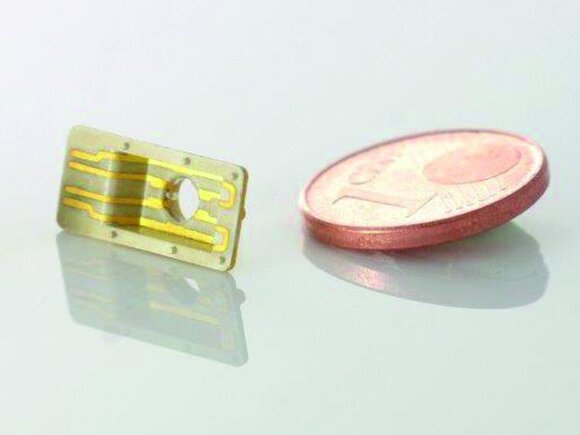

Small Parts - Big Challenges

Microtechnologies of Plastics

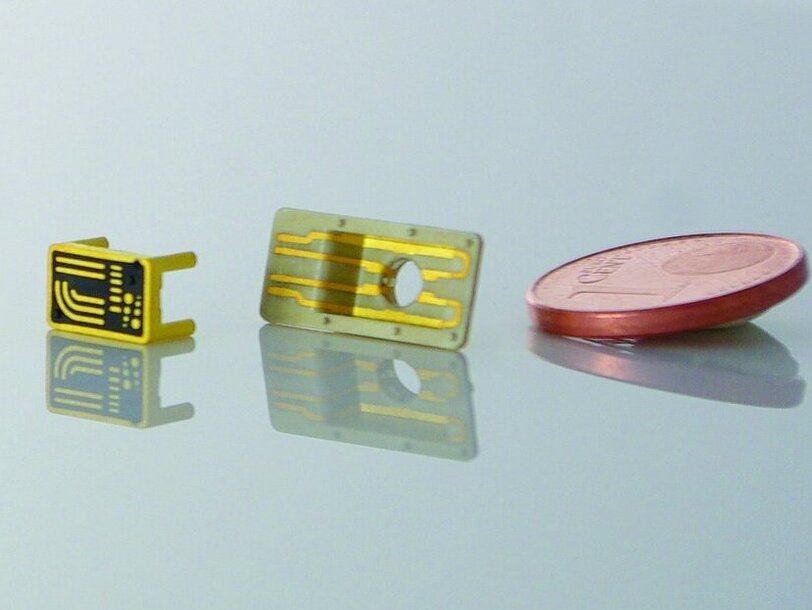

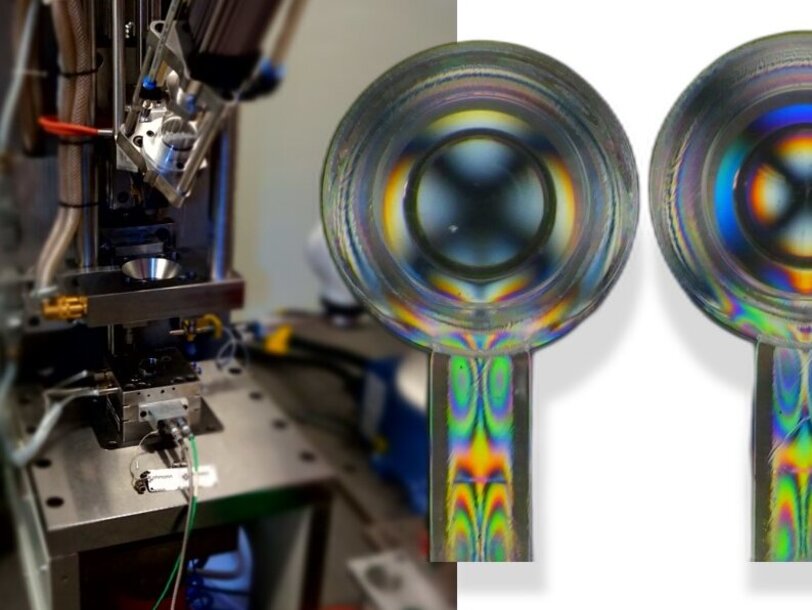

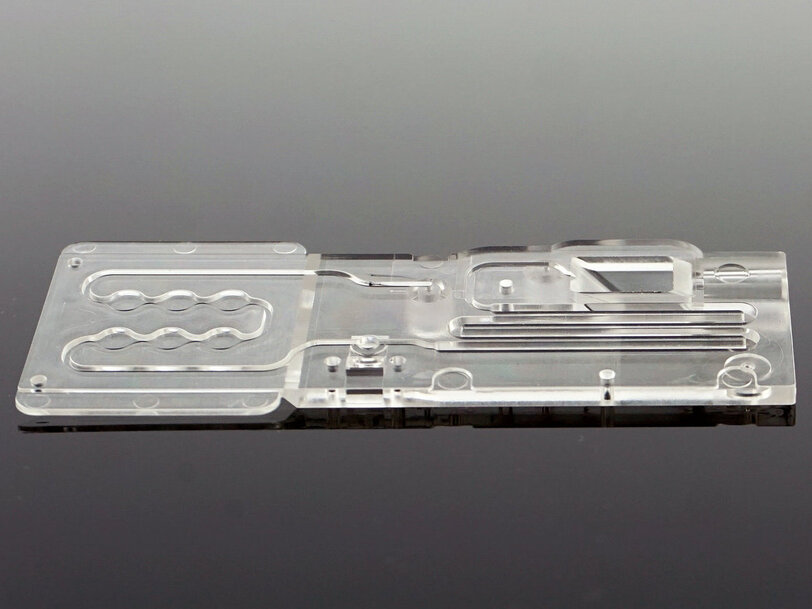

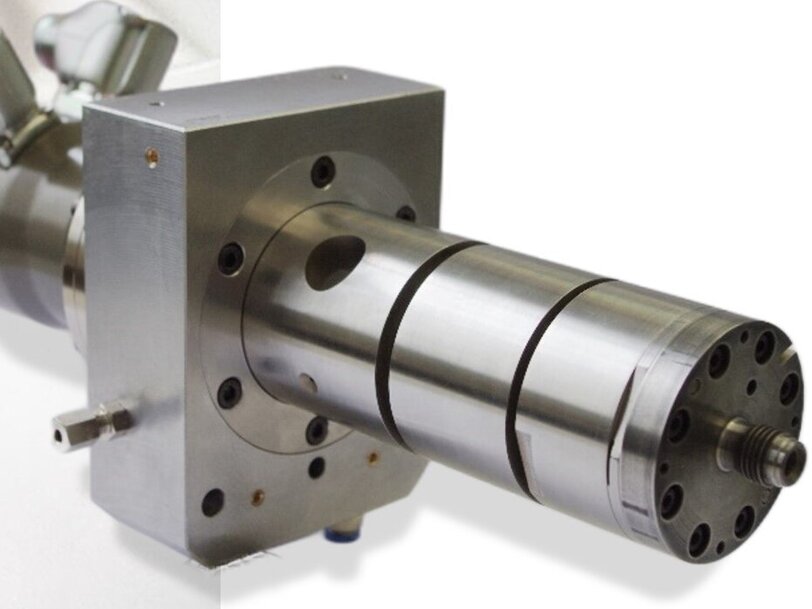

The miniaturization of many molded parts and assemblies is progressing unceasingly. The demands on the production processes for micro-molded plastic parts are increasing at the same rate, because small dimensions mean maximum precision and also special handling of the small amounts of material in the process. In microtechnologies of plastics, the focus is on mastering the preparation of the smallest quantities of material, reducing the dwell times under temperature load for sensitive materials, keeping the process parameters in multi-cavities constant, resource efficiency and cost savings in the processing of high-performance plastics, and adequate handling of the smallest components in downstream processes.

Our MiKA - Application Center for Microtechnologies of Plastics covers the entire process chain for the production of microapplications. First and foremost, we see ourselves as your partner for all industries in which microtechnologies of plastics solutions are required - from feasibility studies in micro injection molding and micro structuring to series production. Extensive and modern equipment as well as our highly qualified team of specialists are at your disposal to meet your requirements.

"/>

"/>