INNOVENT e.V. Technologieentwicklung

Demolding improvement in injection molding

At the end of every injection molding cycle is the demolding process. This often involves problems that cannot be solved effectively by technological variations. This is due to decisions made in advance with regard to material selection, plastic and process-relevant molded part design, and mold design, which sometimes result in unfavorable conditions during demolding that consequently lead to quality losses.

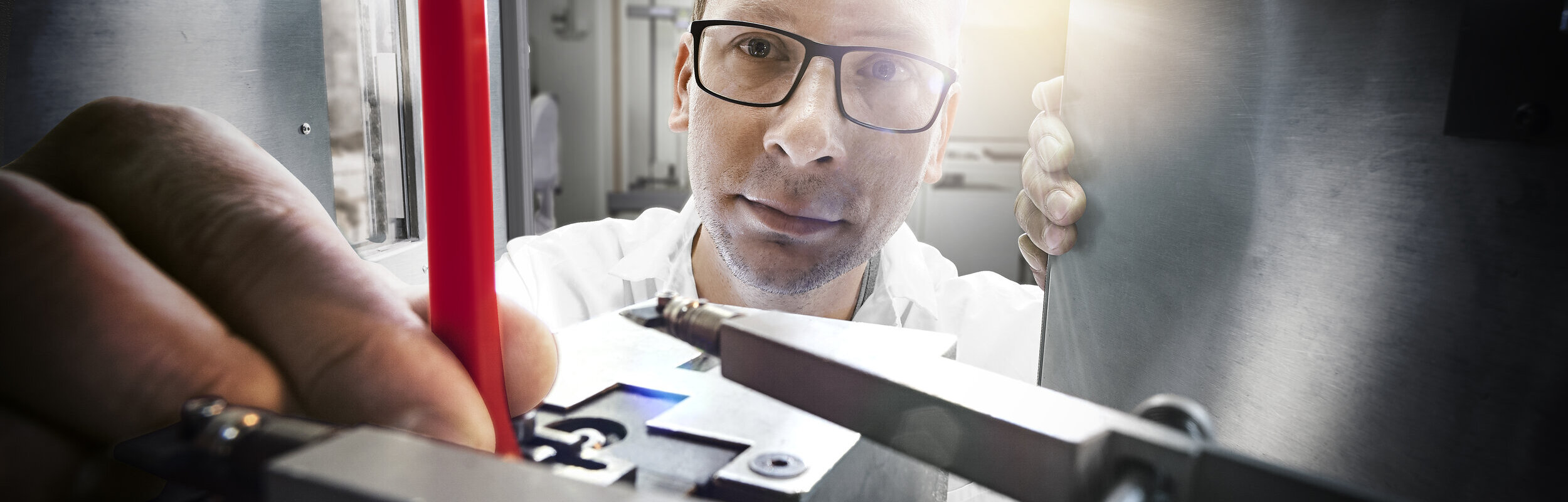

In order to investigate the demolding behavior and improve it through targeted measures, the KUZ has developed a metrological approach aimed at achieving practice-relevant results and allowing an analysis of the effectiveness of mold coatings or additives, for example.

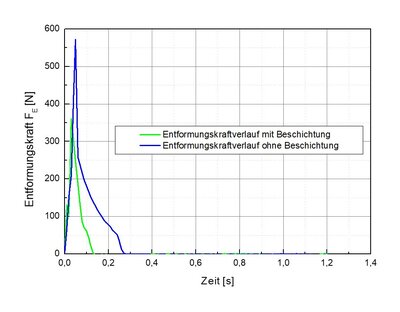

This measuring tool has achieved added value for INNOVENT e.V. Technologieentwicklungin Jena for evaluating permanent release coatings based on novel sol-gel coatings, in that qualitative and quantitative statements on improving demolding behavior can be derived by comparing different coatings (see diagram, right).

The demands on the coatings are high, because they must be mechanically and thermally very stable for the injection molding process in order to compensate for the shear forces and melt temperatures that occur. Positive side effects such as minimization of mold wear, expansion of the potential for process optimization (saving of resources and energy) can be determined and measures for individual coating tasks can be derived.

Detailed conference contribution Technomer- Injection Molding Section

Services provided by the KUZ in the project

- Carrying out demolding force measurements on the injection molding machine

- Verification of the influence of additives or mold coatings on the demolding behavior

- Determination of the maximum demolding force, the force impact as well as the adhesion tendency at the mold surface

In collaboration with

Innovent e.V. Technology Development Jena

Dr. Sebastian Spange | ss2noSpam@innovent-jena.de | +49 3641 28 25 51

Dr. Sven Gerullis | sgnoSpam@innovent-jena.de | +49 3641 28 25 51

Contact

Nico Reimann

+49 341 4941-620

reimann@kuz-leipzig.de