Caparol Industry Solutions GmbH

Injection molding rheology for practical results

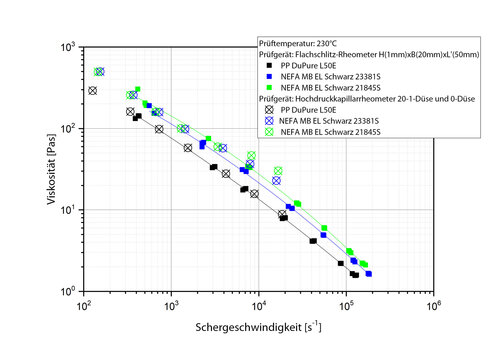

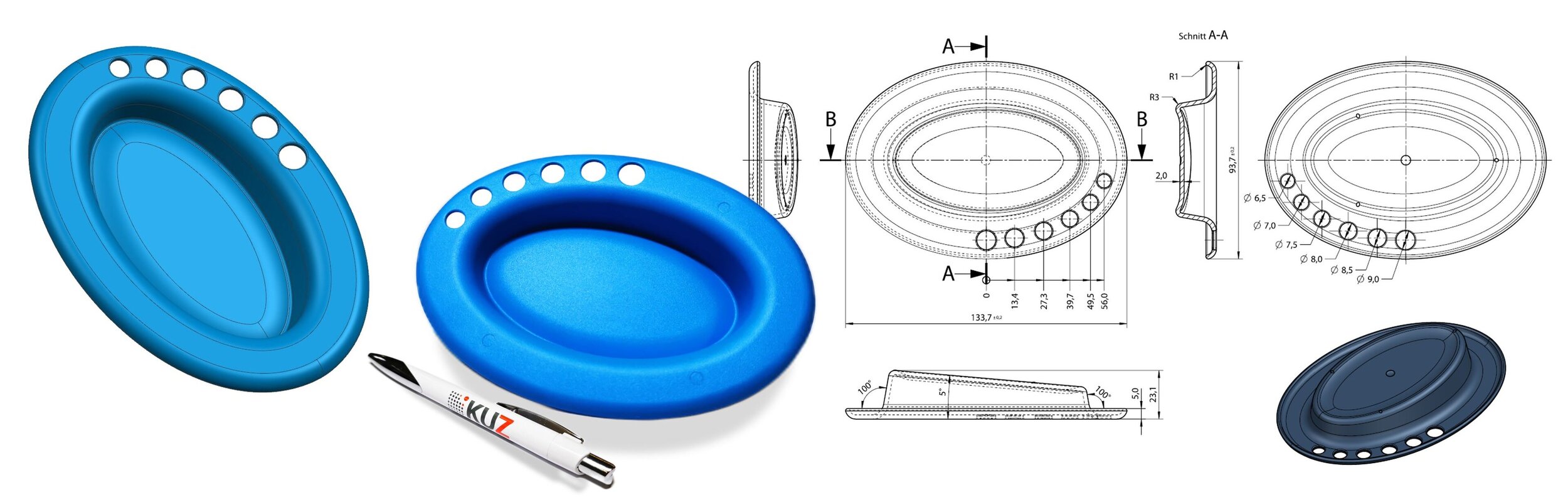

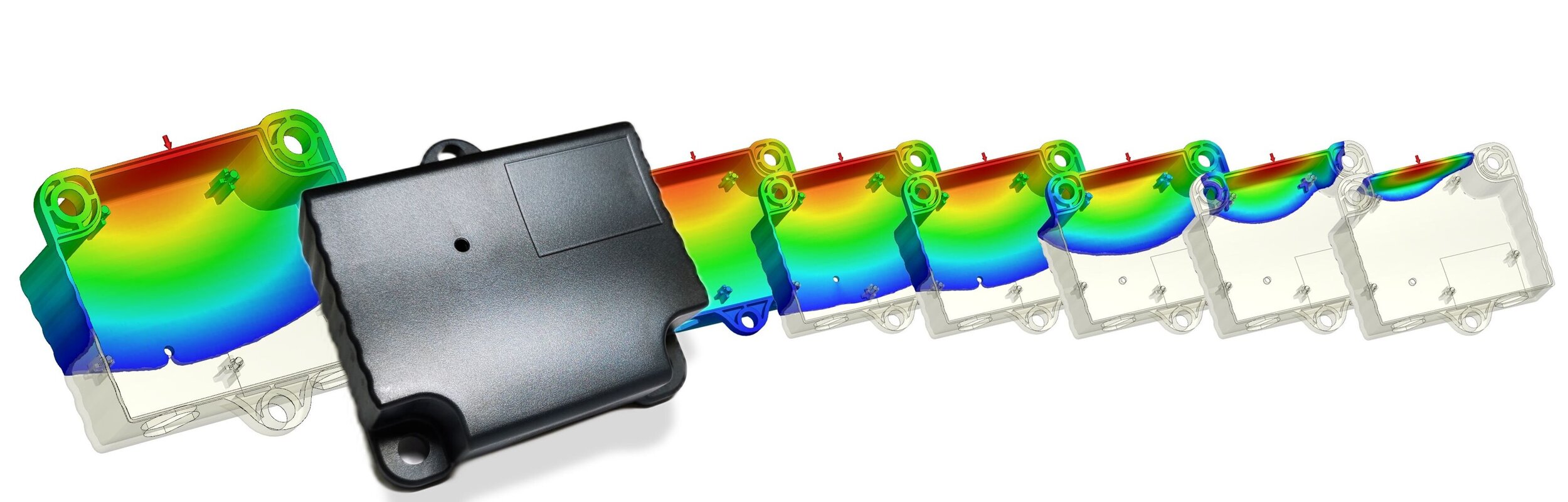

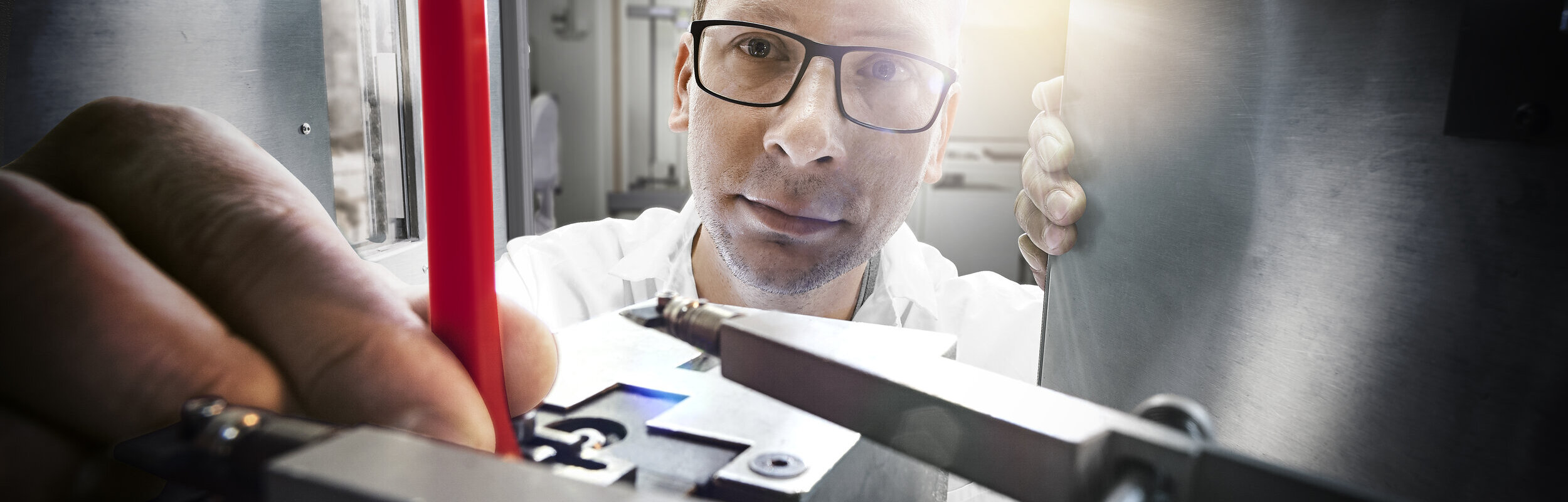

To determine the rheological property profile of carbon black-filled compounds from Caparol Industrial Solutions GmbH, the wide range of services offered by the KUZ Leipzig was utilized. In addition to classical rheological test methods, including measurements with the high-pressure capillary rheometer and application-oriented injection molding tests with a flow spiral test mold, flow curves were also determined using an injection molding rheometer developed at KUZ Leipzig. Injection molding rheometers offer the advantage that they can be used directly on the processing machine and thus allow practical statements to be made on the flow behavior of the plastics or compounds under investigation.

The results contain information on the material influence by the shear occurring in injection molding during the melting process as well as findings on the dwell time in the plasticizing cylinder. Furthermore, viscosity changes due to the addition of additives or residual moisture influences can be directly detected.

This added value in material characterization enables Caparol Industrial Solutions GmbH to improve the marketing of its new products, as the information on processability facilitates acceptance.

Services provided by the KUZ in the project

- Carrying out viscosity measurements on the injection molding machine

- Evaluation of the raw data into usable viscosity data

- Verification of the influence of additives on the flow behavior

- Comparative measurements with flow spirals taking into account the solidification behavior

In collaboration with

Caparol Industrial Solutions GmbH / Werk Nerchau

Dr.-Ing. Matthias Hübner | matthias.huebnernoSpam@caparol-cis.de | +49 34382 704 58

Contact

Kathrin Klamt

+49 341 4941-606

klamt@kuz-leipzig.de