Getting plastic into shape

Injection molding

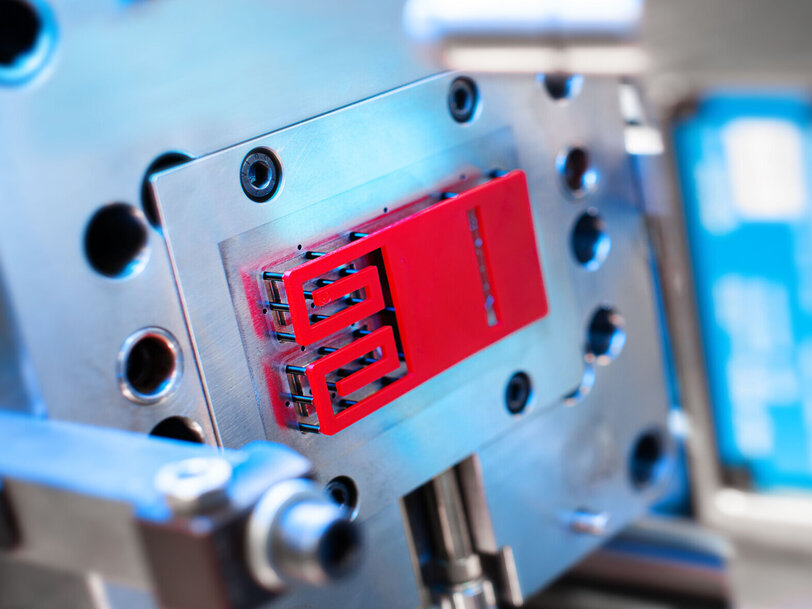

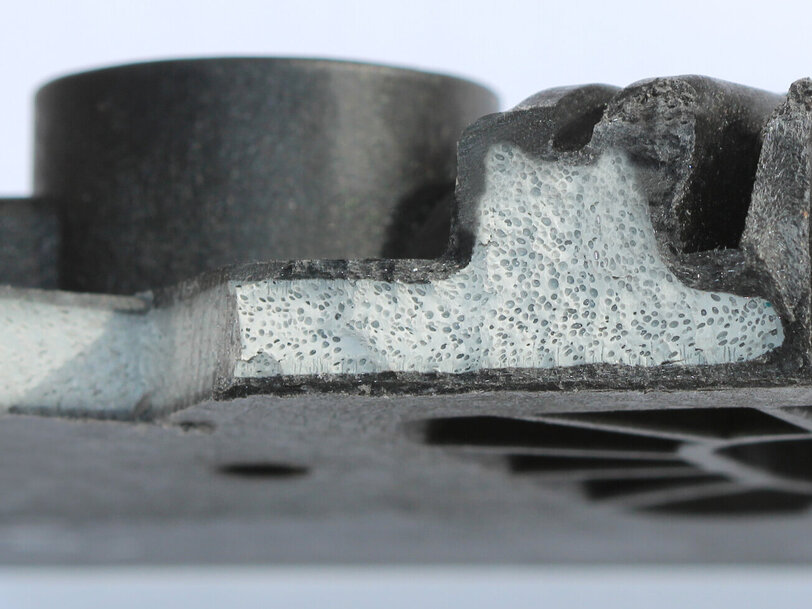

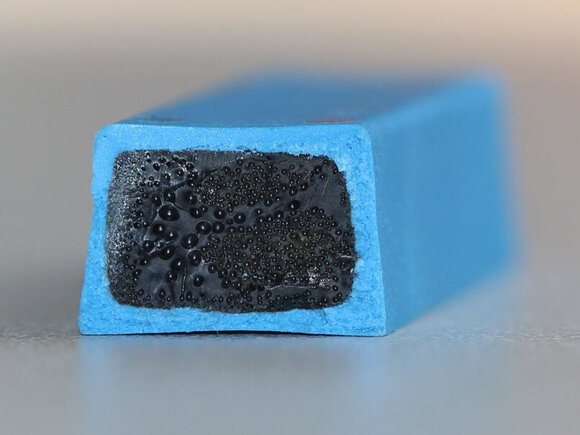

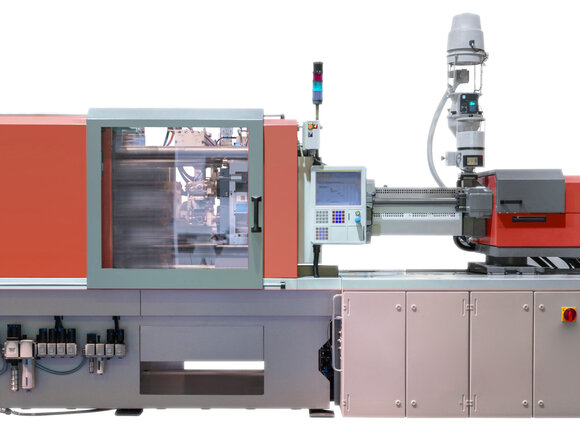

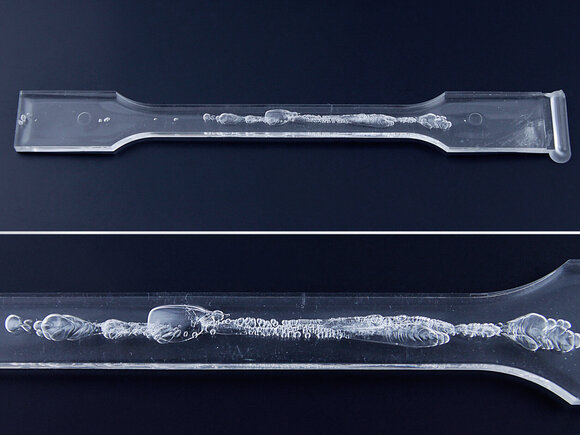

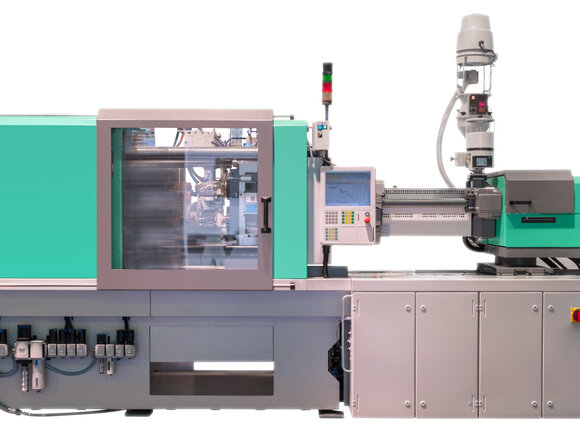

The injection molding process is predestined to bring PLASTIC into SHAPE. Many innovations in technical parts are based on combinations of the many different process variants or newly developed special processes. Common to all of them is the process sequence of preparing a plastic melt, injecting the melt into a closed cavity and cooling the material under mold constraint.

We use the extensive experience of our experts and the wide-range equipment of our technical center to examine every component of your injection molding process. We lighten your components, integrate functions cost-effectively and increase the robustness of your processes - making them more energy- and resource-efficient. Together with our experts in component and mold design, we work with you to realize a successful product. In addition to "getting plastics into shape" in line with the material and the process, we focus on the topics of functionalization, lightweight construction and process optimization using appropriate technologies and, above all, combining them.

"/>

"/>