KIScha - AI-assisted foam characterization

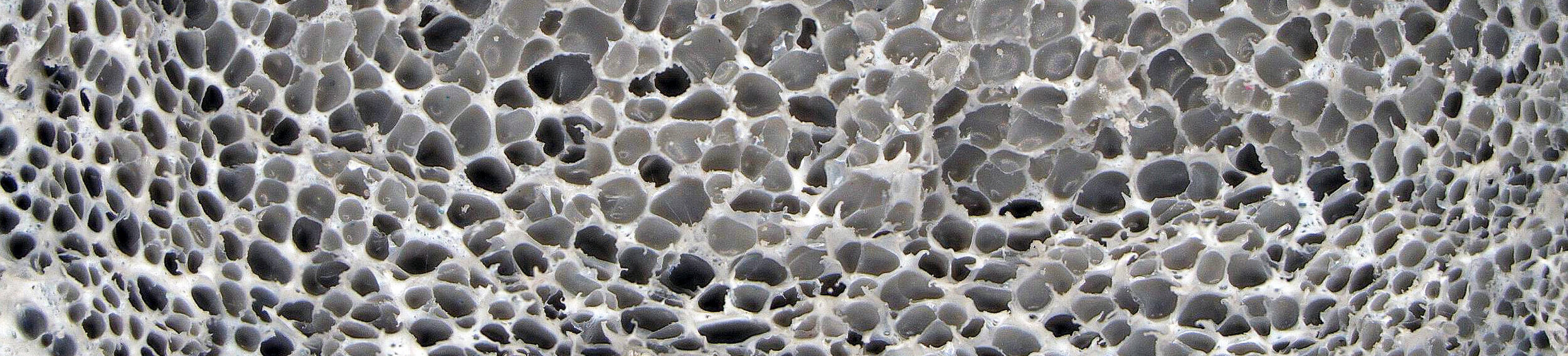

Foam characterization on TFIM components using AI-assisted fracture surface analysis.

The aim of the project is to develop a method for characterizing and categorizing different foam structures using an artificial intelligence module. Machine learning methods are used to map a relationship to defined quality variables such as bubble size, distribution and shape in a model from collected measurement data. The resulting model is used to automatically categorize the molded parts according to the specified quality criteria.

Thermoplastic foam injection molding (TFIM) is an established process for the production of cost-effective lightweight components for large-scale production. In contrast to extrusion foams, various defect patterns can occur due to the process. Typical defect types are insufficient foam formation, the formation of large cavities or bubble planes, or deviations from the spherical shape such as bubbles that are oval in the flow direction or drop-shaped. Depending on the characteristics, the consequences can lead to mechanical impairment or even component failure. Classical methods of characterization such as thin section, microscopy and computer tomography require qualifications, time and effort and are unsuitable for quality control during production.

The aim is to develop a fast, simple and automated fracture surface characterization for quality assurance. The sample preparation should be reduced to a minimum.

Duration: 11/2019 - 04/2022

Contact

Dr. Mathias Kliem

+49 341 4941-610

kliemnoSpam@kuz-leipzig.de