Glass furnace reinforced and soot filled

Optimized joint design for infrared welding

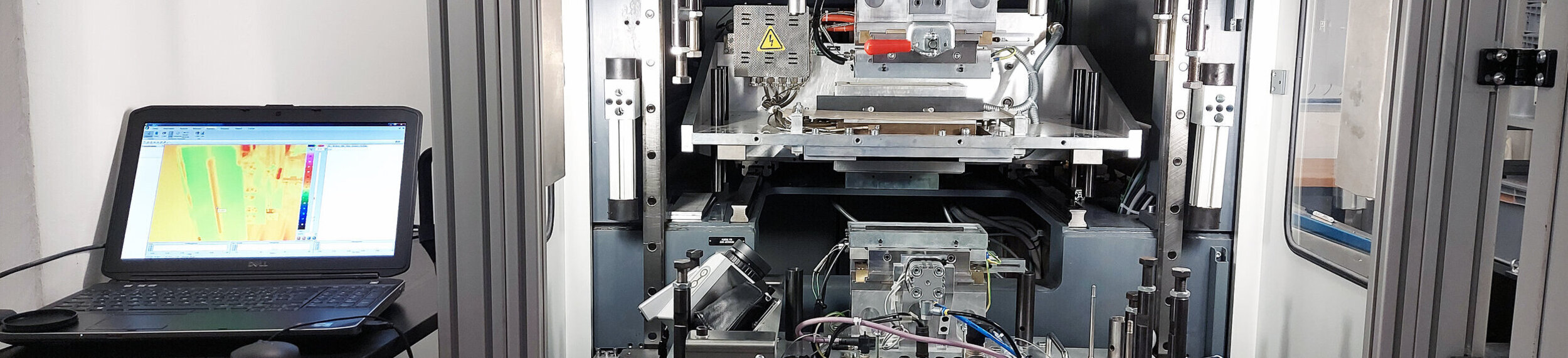

In this research project, new joining seam designs are being developed and investigated for infrared welding of glass fiber-reinforced molded parts made of polyamide. The objective is to be able to cover significantly larger joining distances with heating times that are not excessive. This makes it possible to compensate for the real and usually unavoidable component distortion and component tolerances resulting from the component manufacturing process.

In addition, higher joint strengths can be achieved by increasing the surface area in the joint area. For carbon black-filled molded parts, the achievable melt layer thickness is to be increased. To this end, the relationship between IR emitter distance and temperature control during the heating process will be investigated and optimized.

Duration: 11/2021 - 04/2024

Contact

Ingo Hoveling

+49 341 4941-751

hovelingnoSpam@kuz-leipzig.de