Infrared welding

Joint design for foamed thermoplastic molded parts

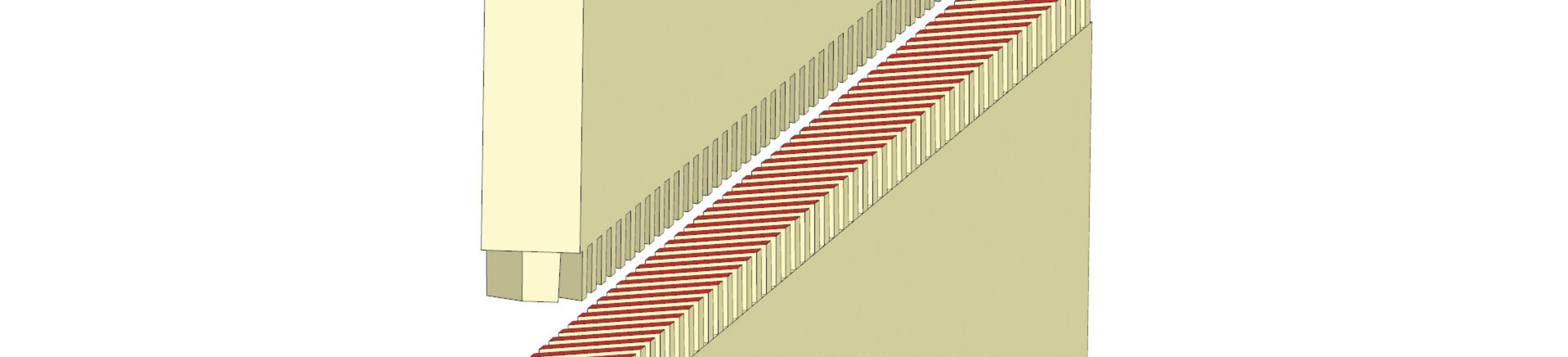

The content of the research project is a modification of the joining seam design for foamed molded parts so that a thicker compact joining zone layer is created. The infrared (IR) welding process is to take place exclusively in the compact area of the component and the foam structure is to be retained as far as possible.

This will be implemented by developing mold inserts, foam injection molding of molded parts and IR welding of the molded parts, combined with CT and strength testing.

Duration: 06/2018 - 11/2020

Contact

Ingo Hoveling

+49 341 4941-751

hovelingnoSpam@kuz-leipzig.de