Covestro Deutschland AG

Manufacturing of micro test specimens for the characterization of small plastic batches

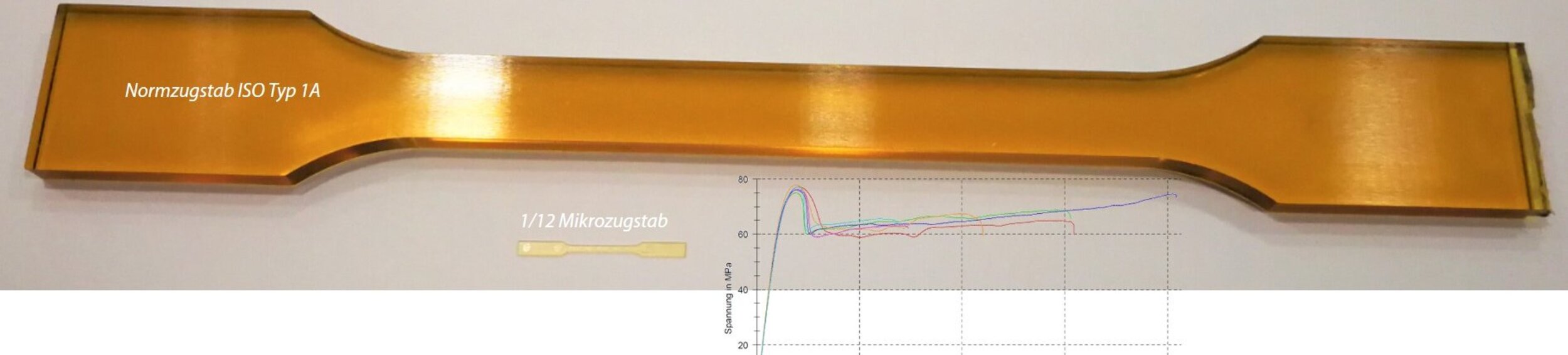

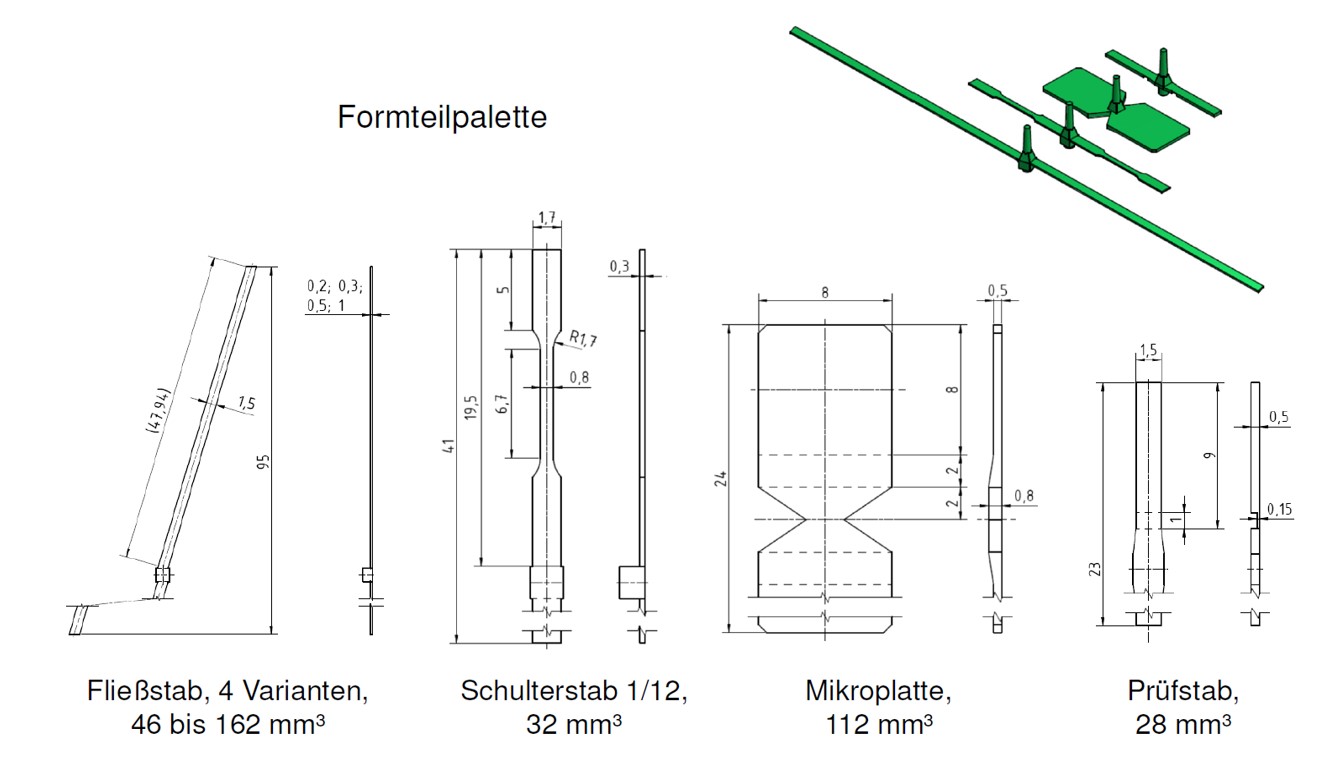

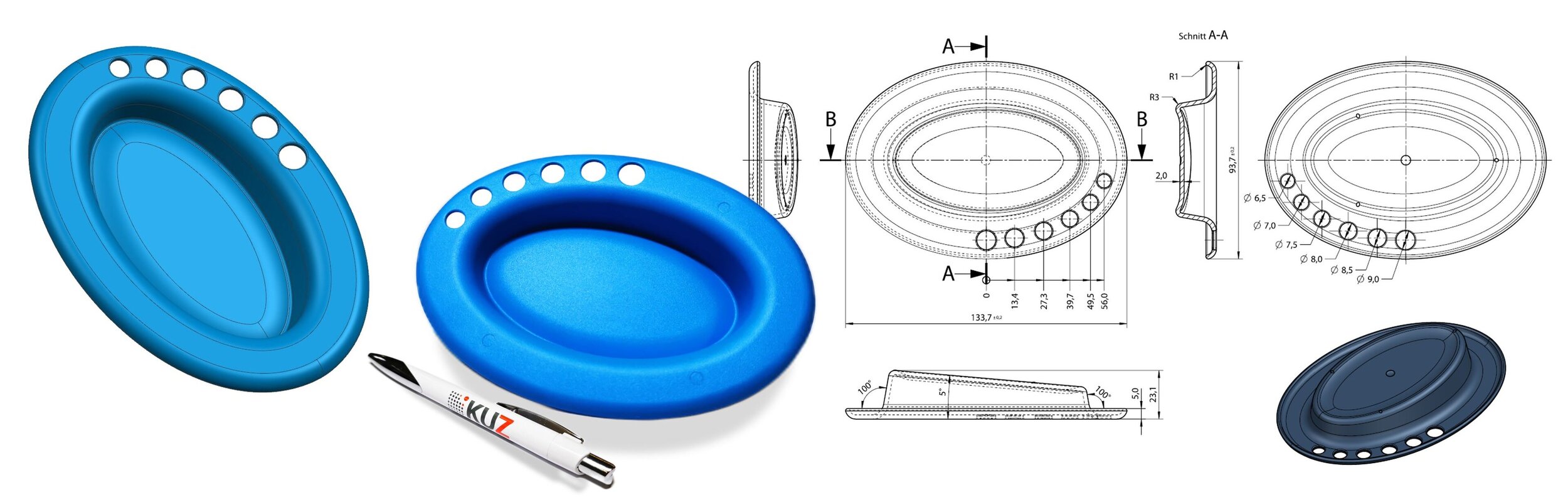

Small plastic batches of a newly developed plastic are provided by Covestro for plasticizing tests on a micro injection molding machine. Only very small quantities of development formulations of the material (approx. 30 gr) are required for this. During the plasticizing tests, the plastic batch is tested for suitability for use in the injection molding process. If the evaluation is positive, injection molding tests are carried out to produce tensile test specimens and test plates, which are subjected to mechanical testing to characterize the plastic batch in terms of its properties. If possible, 1/12 shoulder bars for tensile testing and microplates for hardness testing are to be produced.

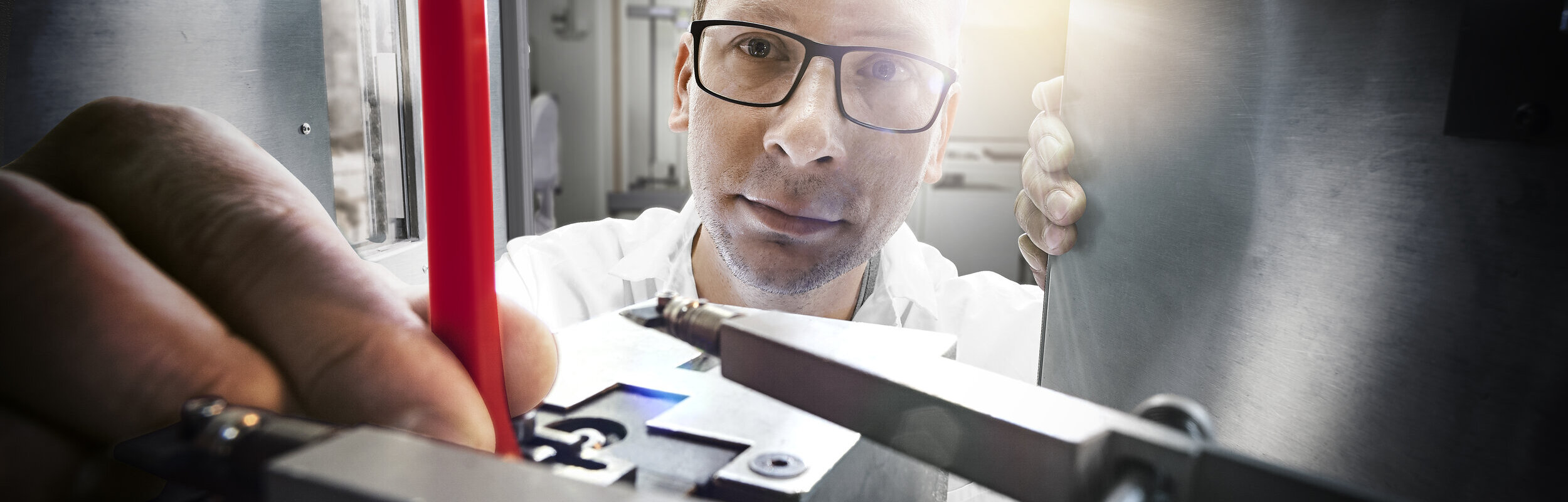

The plasticizing tests were carried out on a formicaPLAST micro injection molding machine available at the KUZ. This is a pure piston plasticizing system with 7 mm pre-plasticizing piston and 3 mm injection piston. This plasticizing system makes it possible to prepare very small batch quantities and thus to produce a defined quantity of micro test specimens. The maximum shot volume of the standard version is 150 mm³.

Compared to the otherwise required material quantity of 3 kg for the production of standard tensile bars in conventional injection molding, only 30 gr. of a laboratory batch are needed for the production of micro tensile test bars. This greatly minimizes the development time by providing a very small required laboratory batch for the production of micro tensile test bars.

Contact

Steffen Jacob

+49 341 4941-704

jacobnoSpam@kuz-leipzig.de