in search of clues

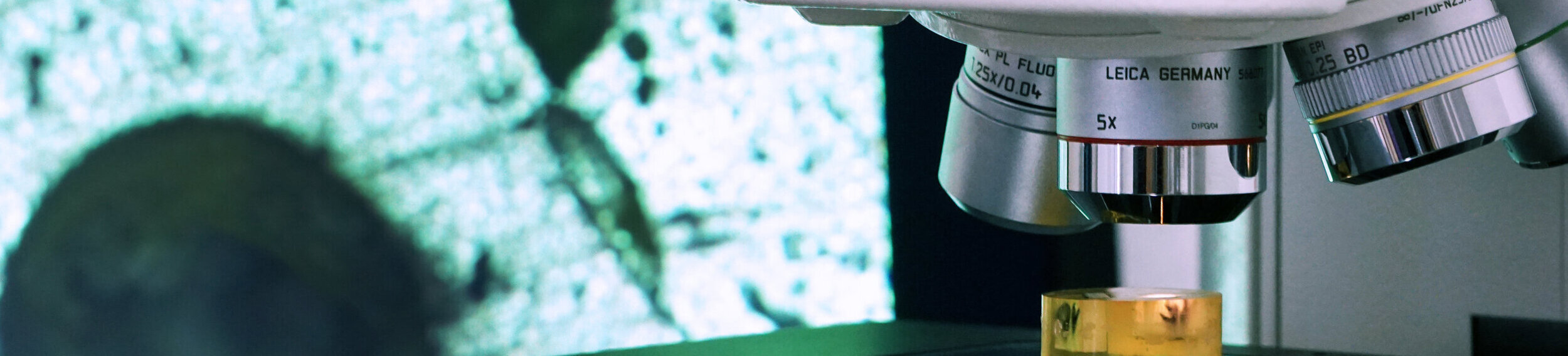

Damage analysis

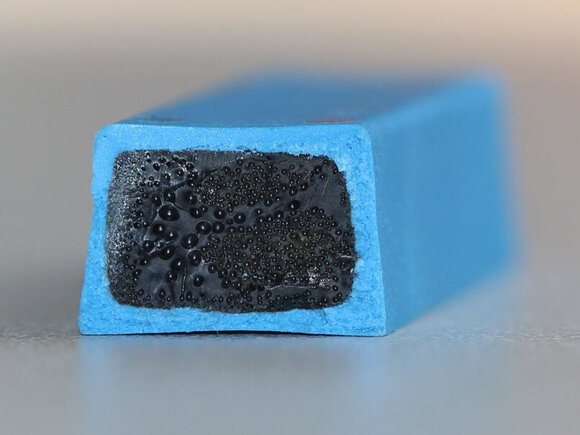

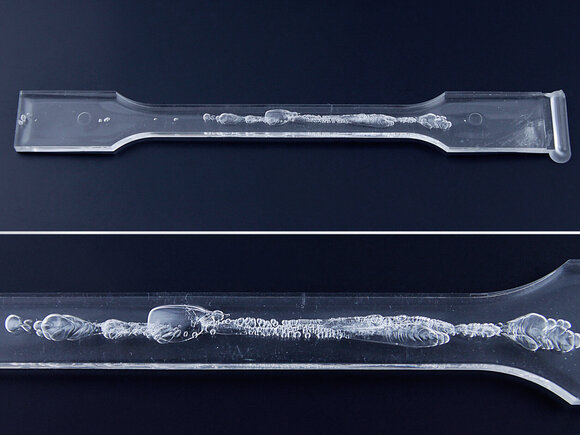

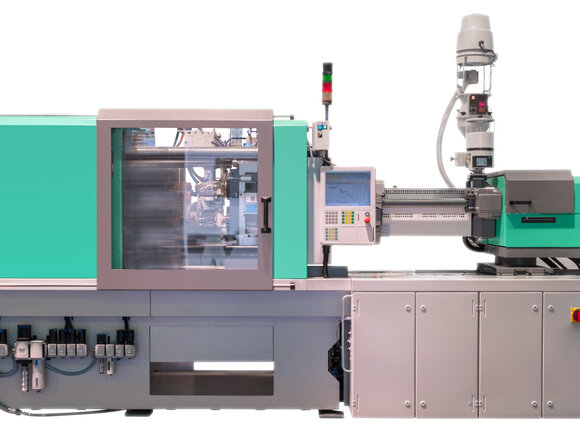

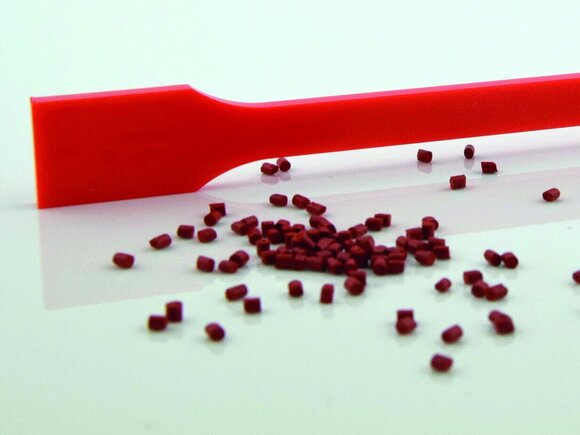

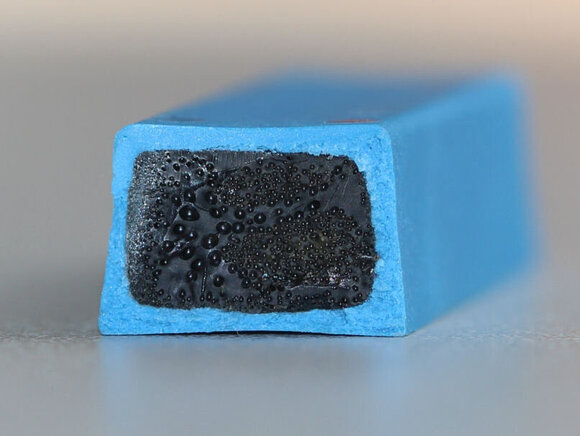

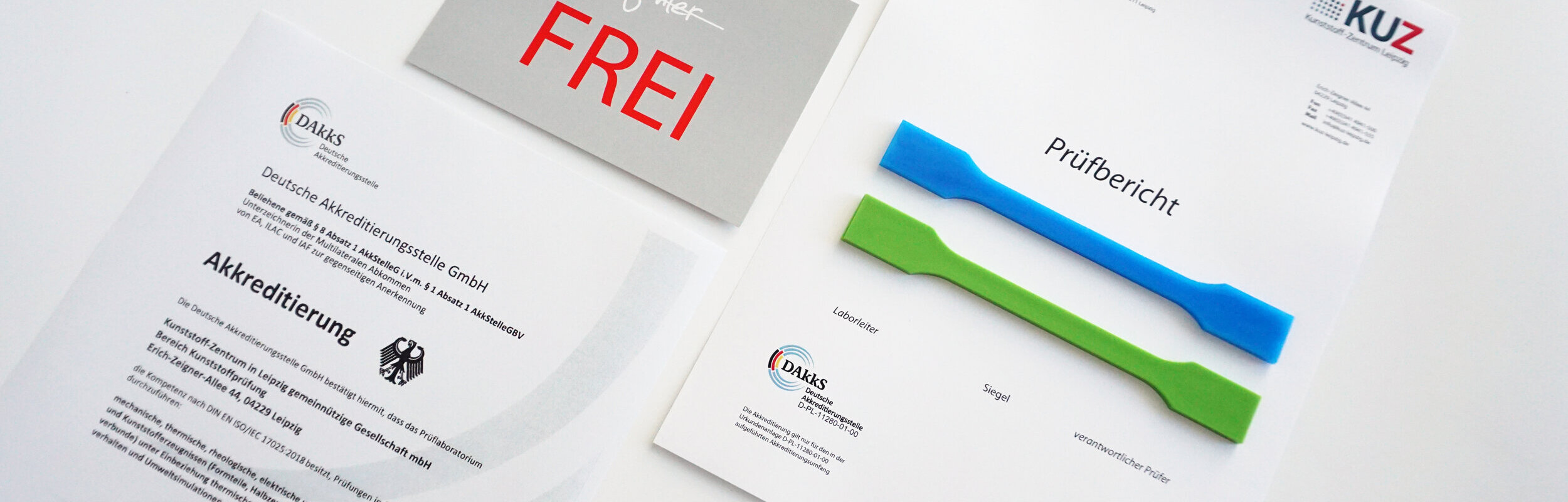

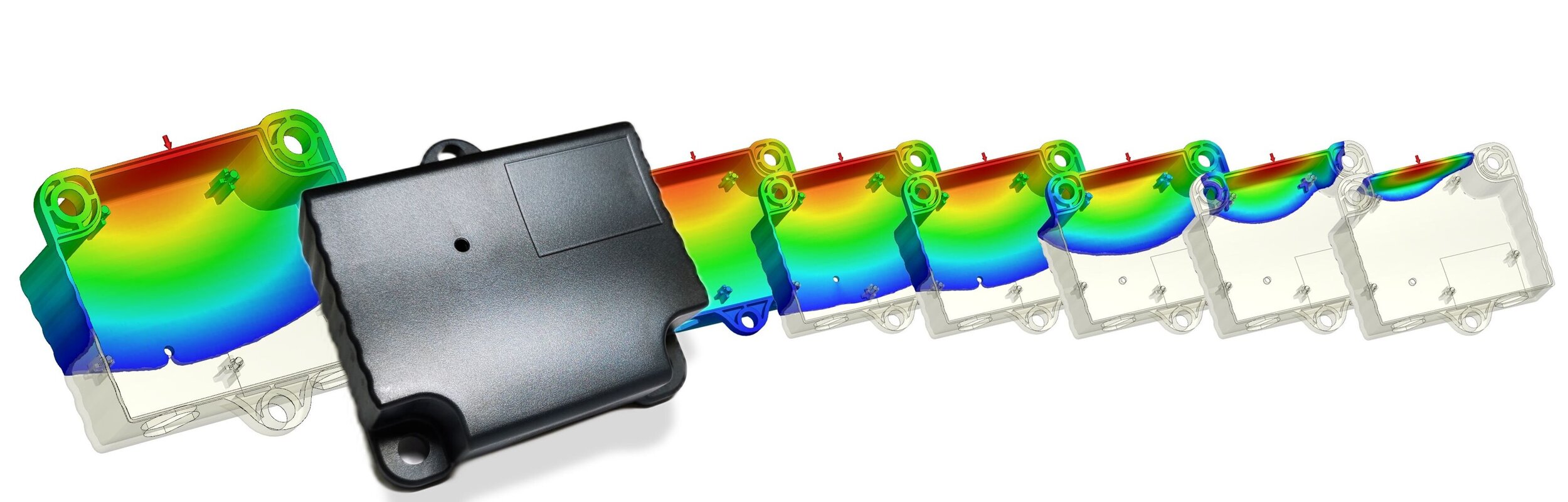

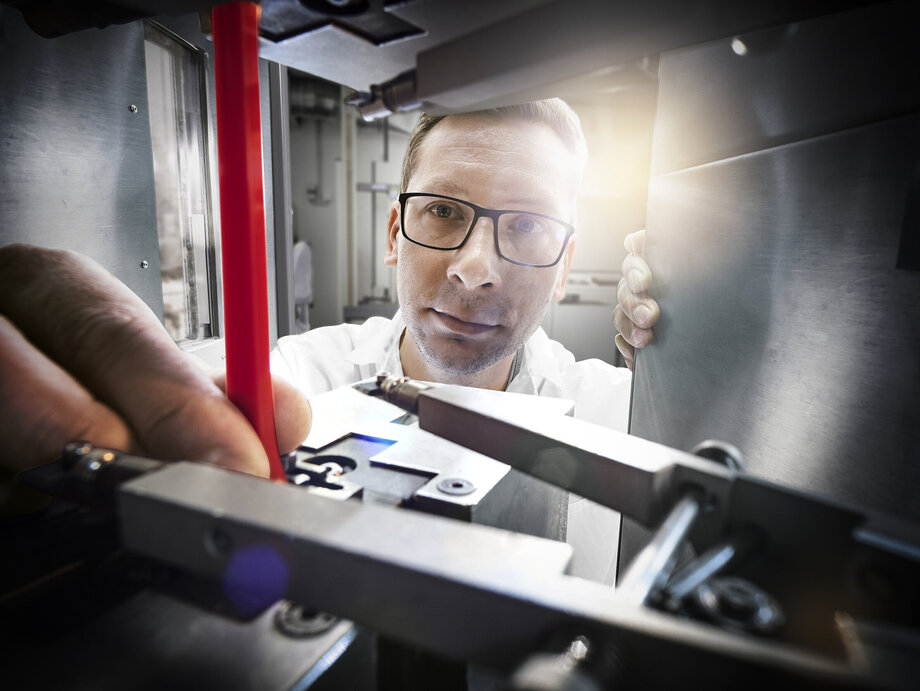

Damage analyses serve to clarify the causes of damage and to reveal the damage mechanisms. They are a prerequisite for damage prevention and make decisive contributions to improving product quality. We have many years of experience in the field of damage analysis of plastic parts, and we would like to support you in "Learning from damage!"

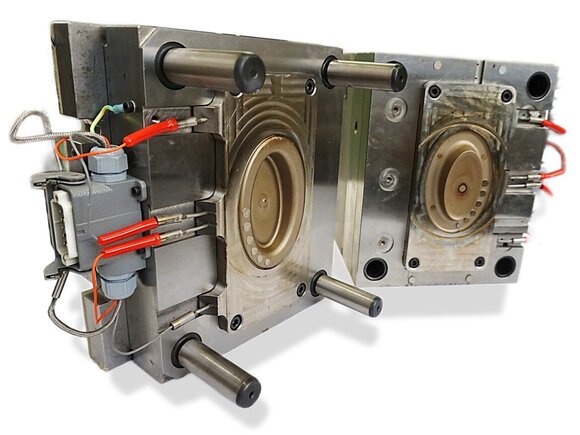

When dealing with damage cases, we follow a systematic approach in accordance with VDI Guideline 3822. So, with closely cooperate with our experts possessing practical experience in the fields of design, processing, testing/characterization and materials science providing the decisive basis for success. For experimental investigations to obtain information about the damage process, we have modern devices and equipment available.

With our help, you can find an optimum of material, manufacturing and component properties for your technical product from a cost point of view.

"/>

"/>