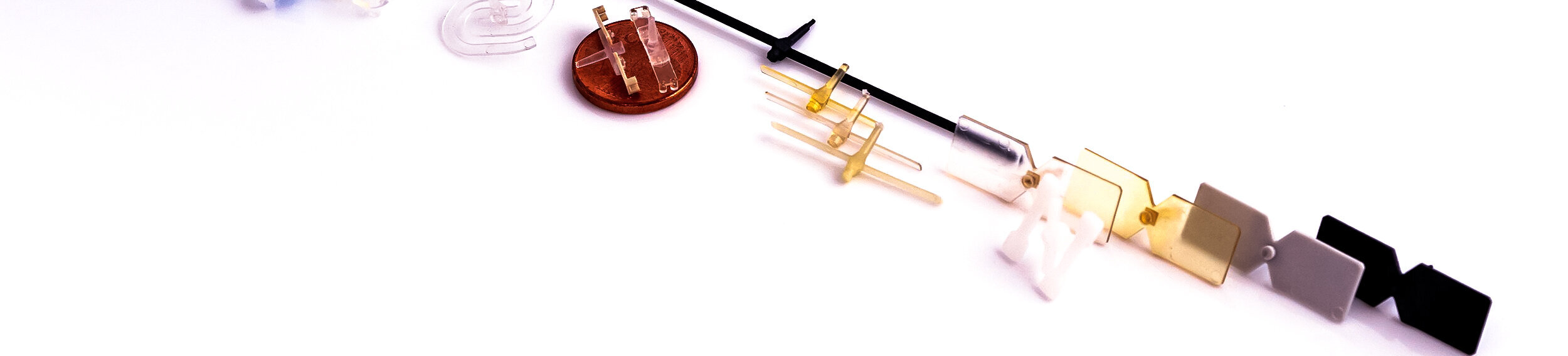

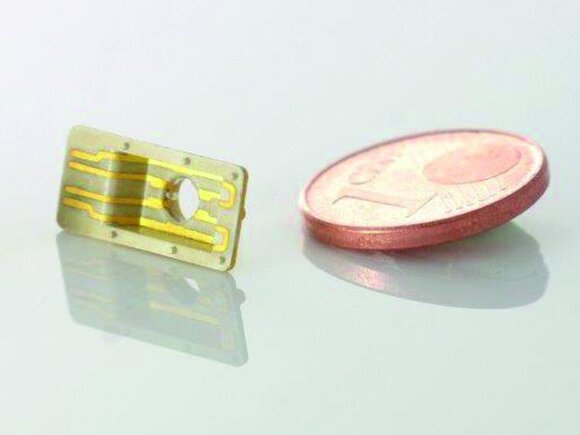

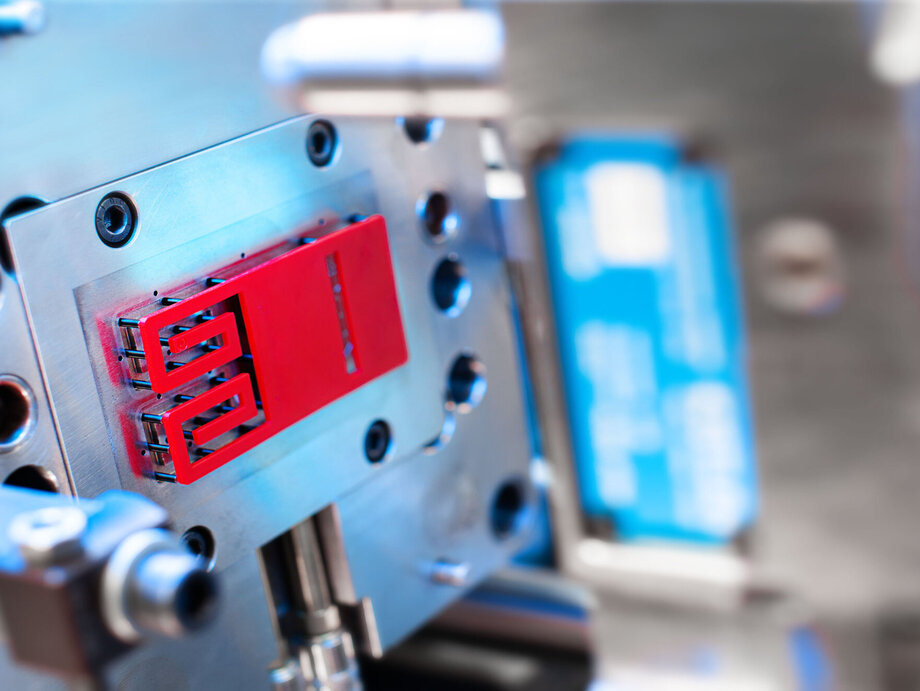

Test specimen made of smallest amounts of material

Micro test specimen

Are you developing a new material and need to test it quickly and efficiently? With injection-molded micro test specimens, even small quantities of plastic can be tested under very precise process specifications. For material development and the development of micro-engineered solutions in general, the production of micro test specimens offers a number of advantages.

Catalog of test specimens (pdf)

- A wide variety of test specimens with different geometries can be produced from less than 50 g of material.

- Very cost-intensive materials can be investigated efficiently and cost-effectively.

- Materials from a laboratory production can be comparatively examined in the accredited test laboratory

- Recommendations for injection molding technology can be efficiently and quickly derived from the production of the specimens.

- Various performance chracteristics, chemical resistance, bondability, etc. can be evaluated.

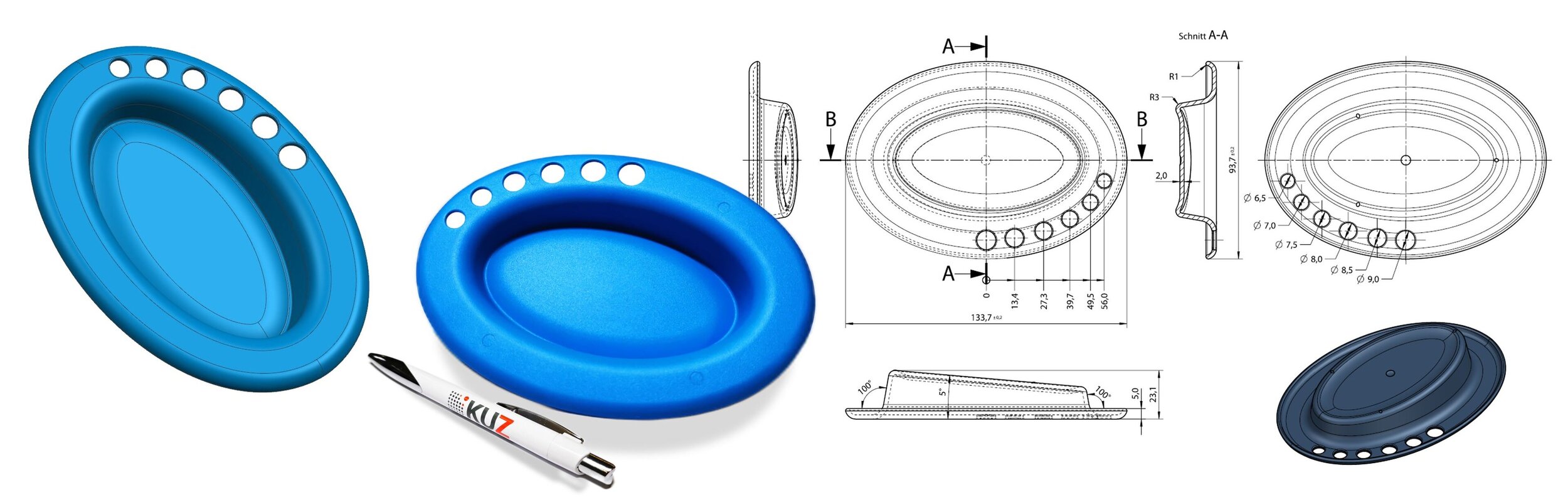

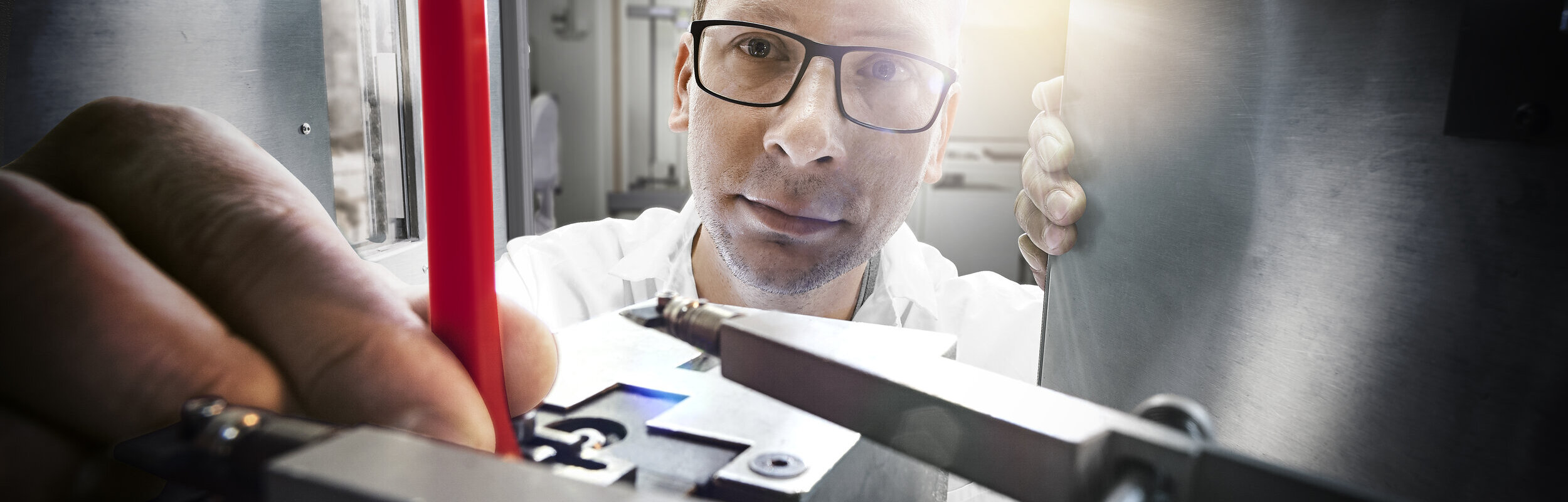

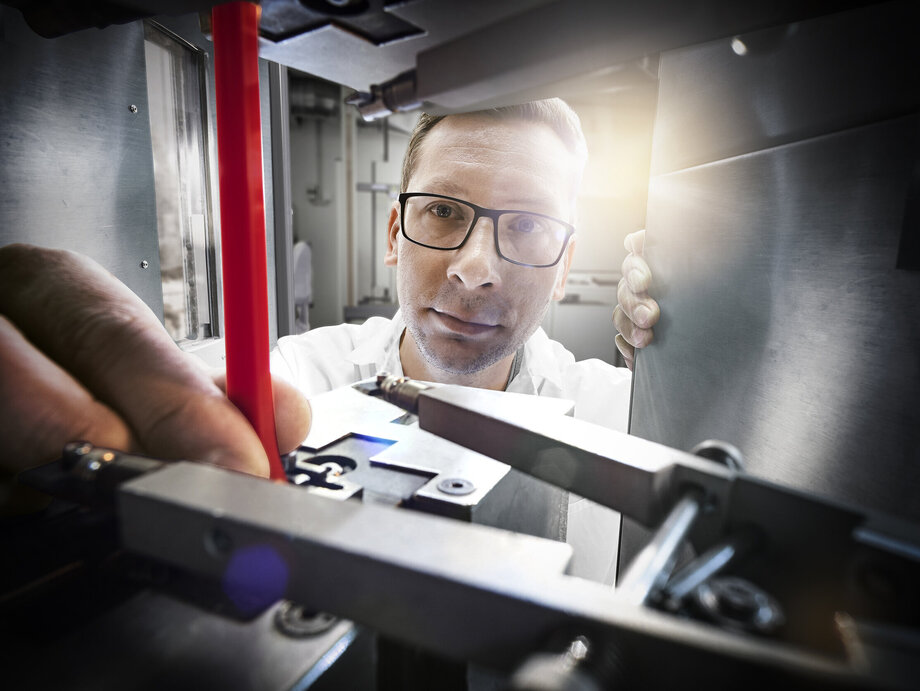

The "formicaPlast" micro injection molding machine developed at the KUZ allows the processing of extremely small shot weights, even for materials that are sensitive to dwell time. Injection molding tools and test fixtures for a wide variety of test specimen geometries are already available for characterizing a wide range of material properties.

Micro test specimens - Why?

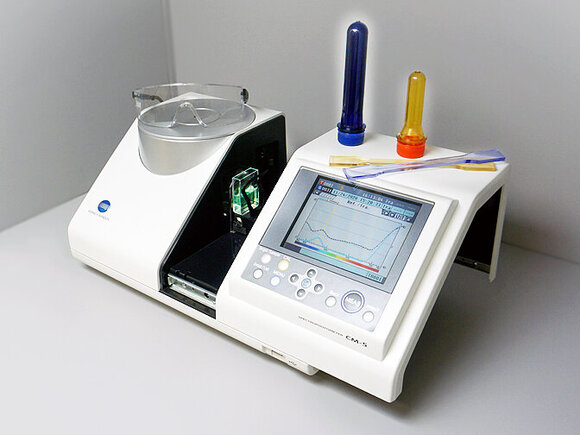

Characterization of the injection molded material

The following test methods, for example, are available for selection:

- Differential scanning calorimetry (DSC) to evaluate the melting behavior and determine the glass transition temperature

- Thermomechanical Analysis (TMA) to determine the linear thermal expansion coefficient

- Dynamic Mechanical Analysis (DMA) to analyze the mechanical behavior under defined dynamic loads

- Determination of microhardness on injection molded micro test panels at room temperature

- Tensile test on micro test specimens 1/12 to determine mechanical properties (only comparable to each other due to scalling effects)

available test specimen geometries(pdf) (micro test specimens in the KUZ molded parts catalog starting on page 16)

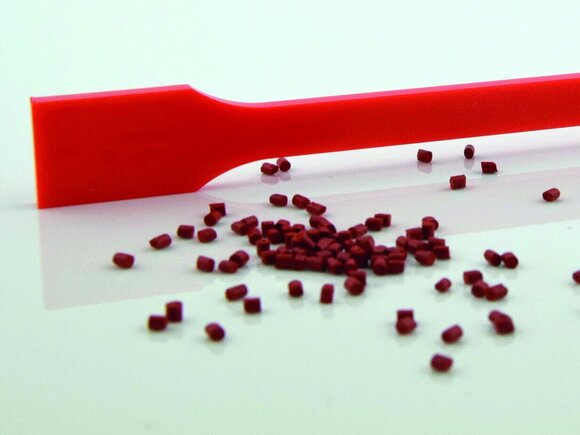

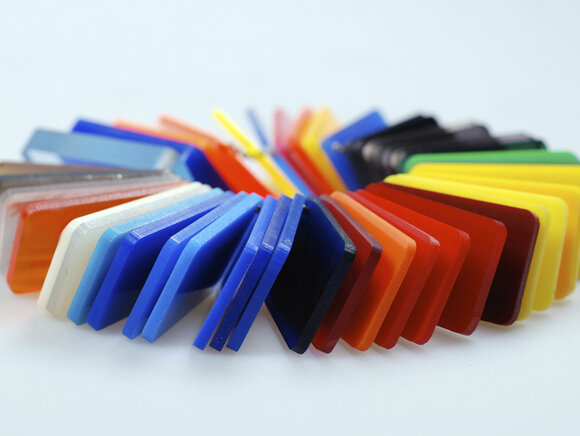

Variety of Materials

The range of materials that can be processed includes:

- Thermoplastics, including high-temperature materials and bioresorbable materials

- Thermosets

- Rubbers

- Solid and liquid silicones

In addition, many experimental materials can be processed in a variety of forms (e.g. granules, powders or flakes).

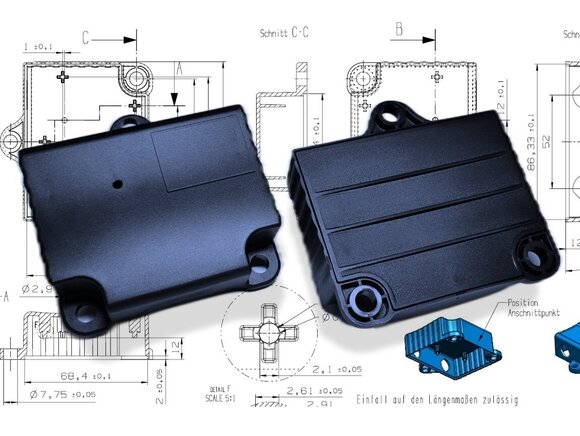

Our services for micro test specimens in detail

- Plastification and injection molding trails with small development batches (<50 gr).

- Evaluation of material suitability for injection molding

- Production of micro test specimens (available test specimen geometries in the catalog of test specimens (pdf, starting on page 16)

- Material characterization in an accredited testing laboratory

"/>

"/>