Compact extruders for microtechnology and much more

Mikroextrusion

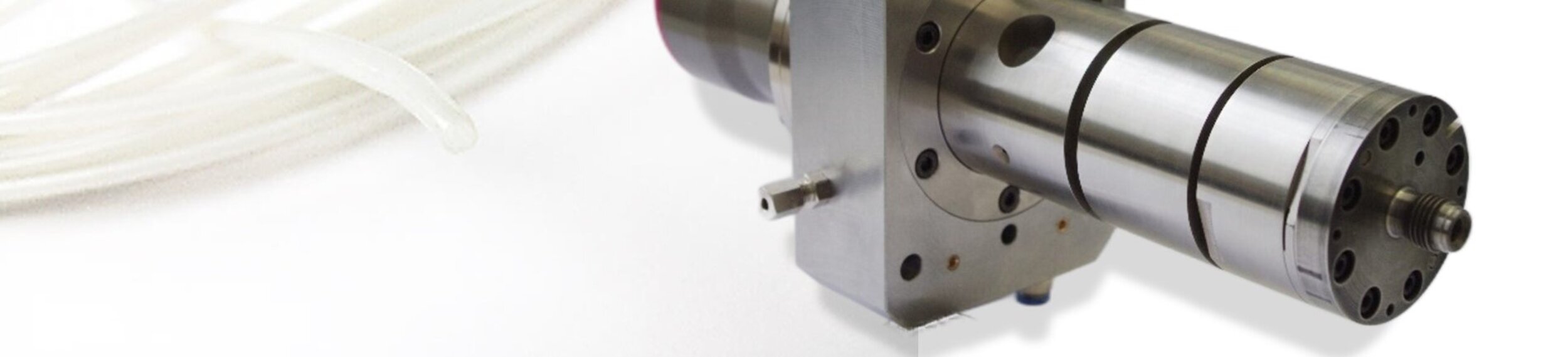

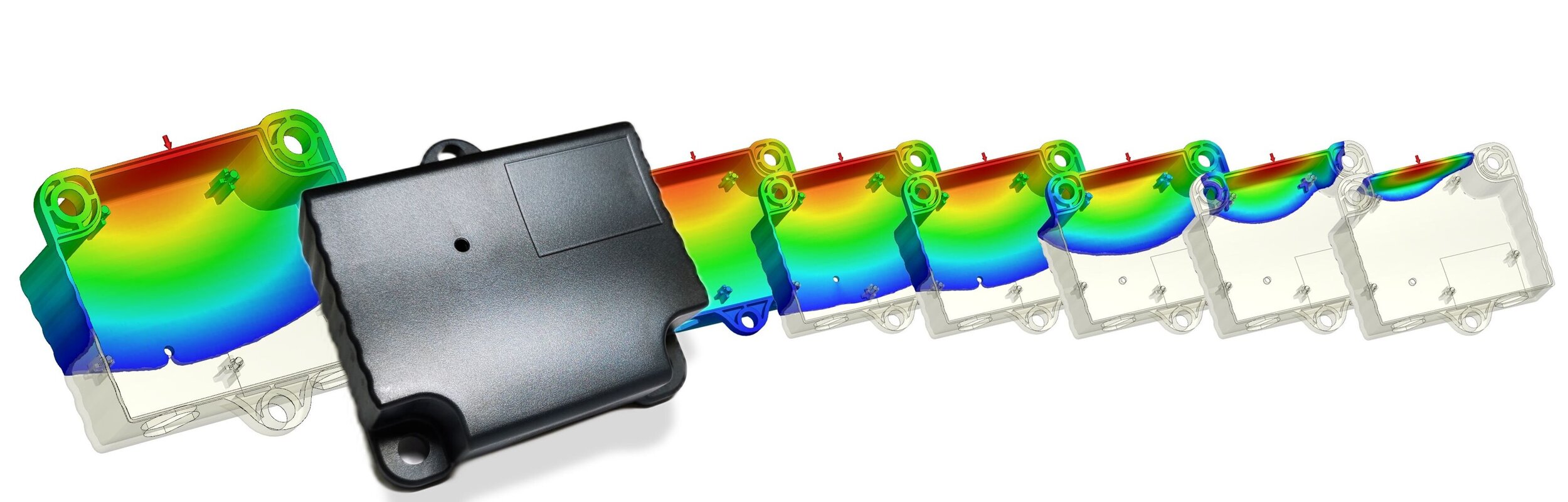

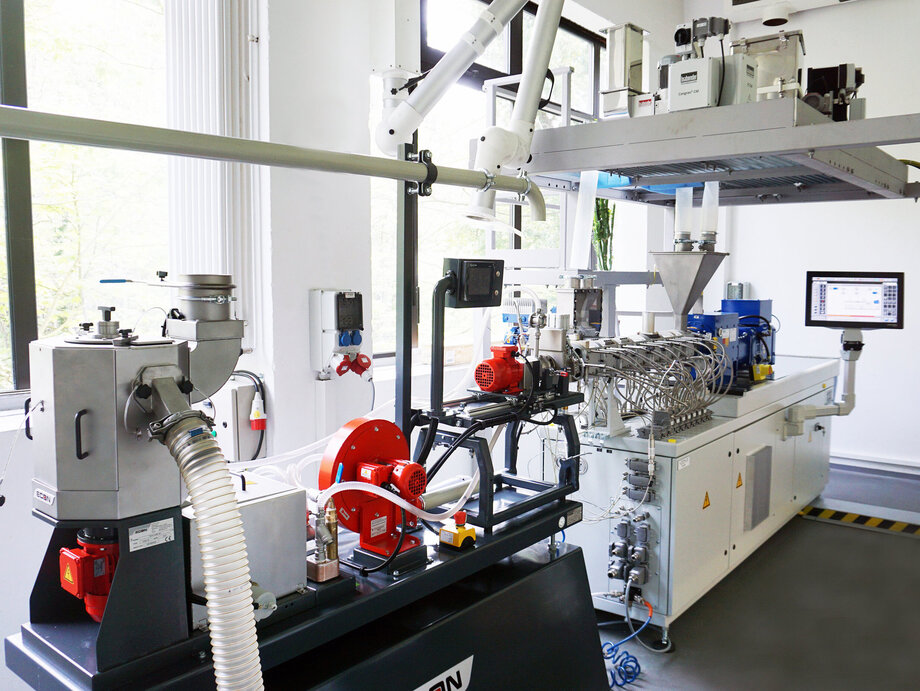

In microtechnology applications, extruders are required for both continuous and discontinuous operation, that provide small melt volumes in an optimally homogenized thermal and material state and at the same time allow short residence times. The principle of disc plastification in miniaturized form is particularly suitable for this purpose. It guarantees the necessary feed rate with very high melt quality for continuous and discontinuous extrusion and for small throughputs.

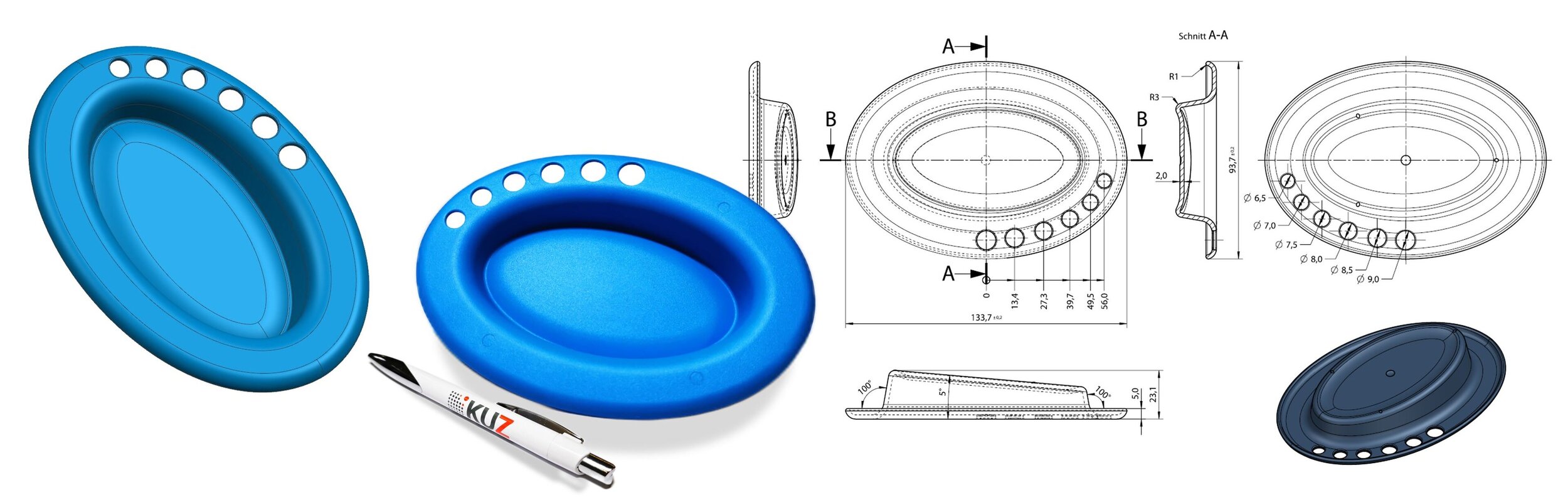

The state of the art shows that an ideal plastification principle is missing for the range of flow rates from 50 to 200 mg/s. In the KUZ, a plastification concept with disc plastification elements and thus a very small L/D ratio has been further developed, which allows the construction of exceptionally compact extruders.

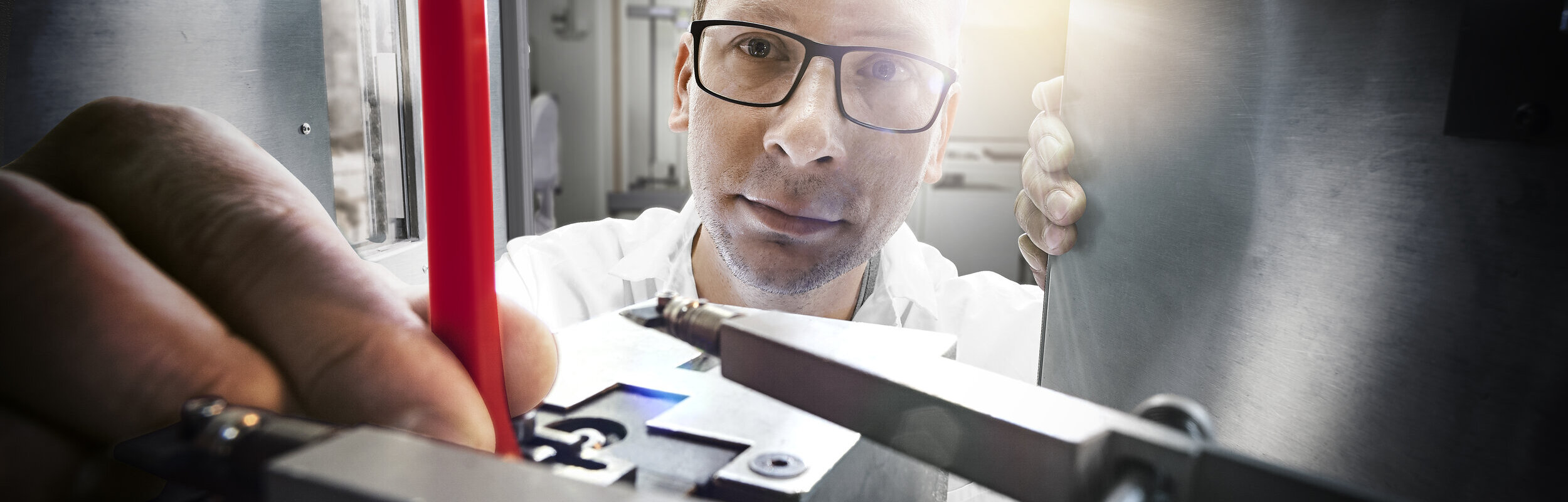

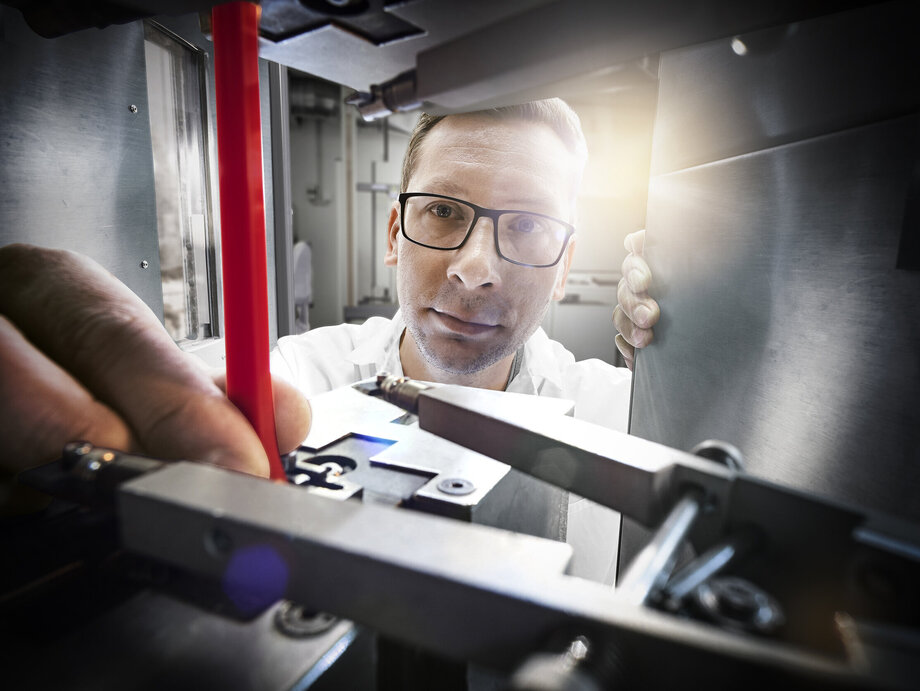

This compact extruder with optimized residence time and a high degree of stiffness can be used as the heart or as a supplement to various plastics processing machines in microtechnology, e.g. as a small-volume extruder for microprofile and multicomponent extrusion or also as a high-performance 3D printing head. Another proven application possibility is the use as a pre-plastification unit in micro injection molding.

Our microextrusionservices in detail

- Sample production of strangextruded semi-finished products

- Tool design and construction

- Construction of micro extruders according to customer requirements

"/>

"/>