Realize lightweight solutions

Foam injection molding

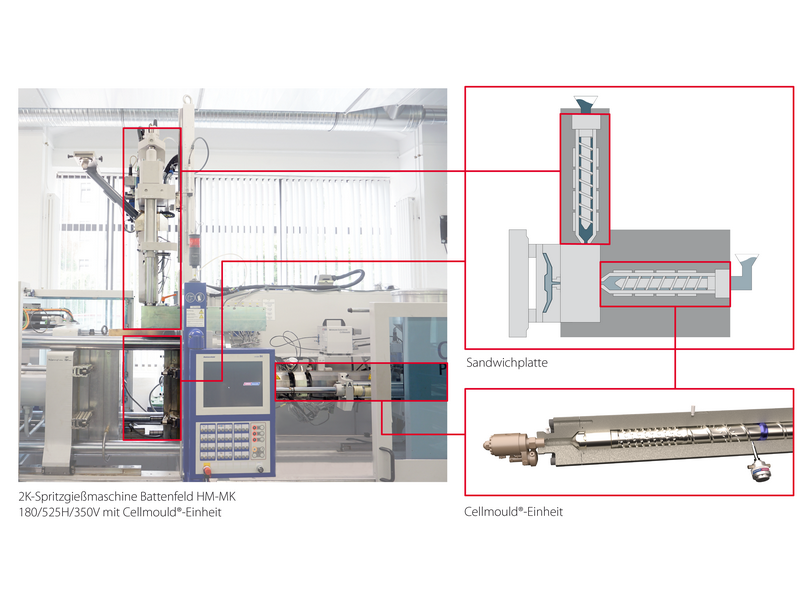

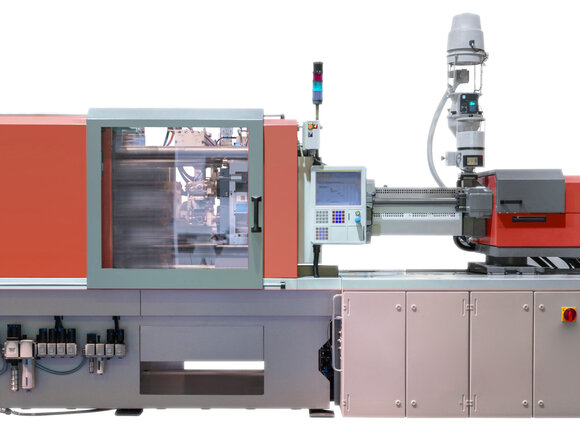

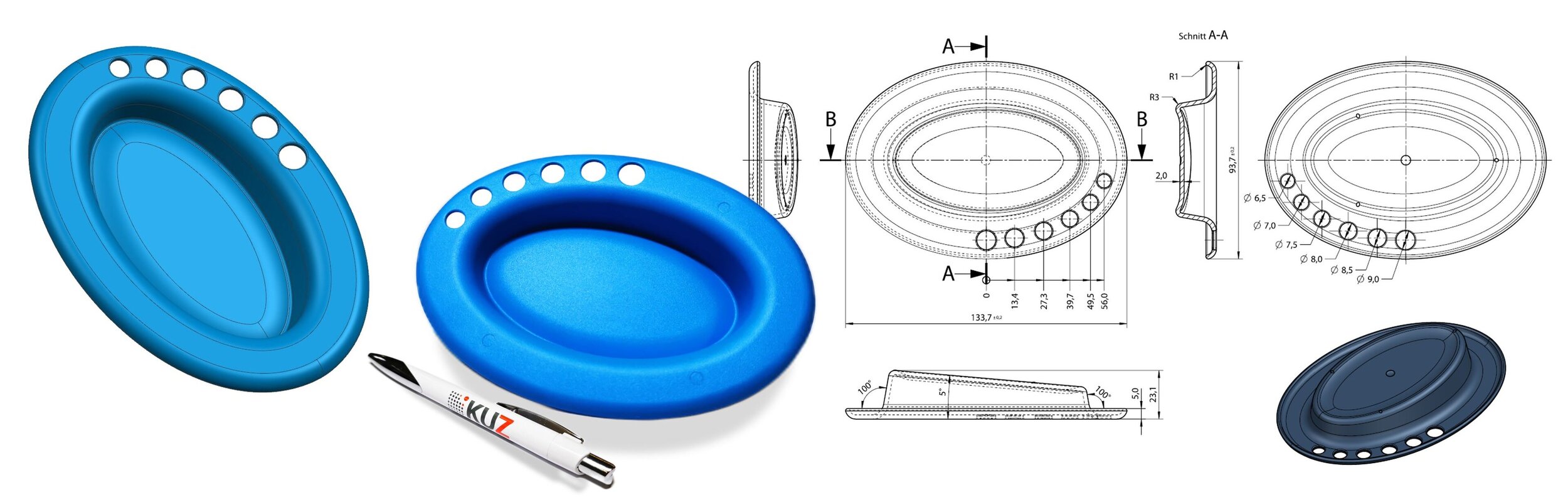

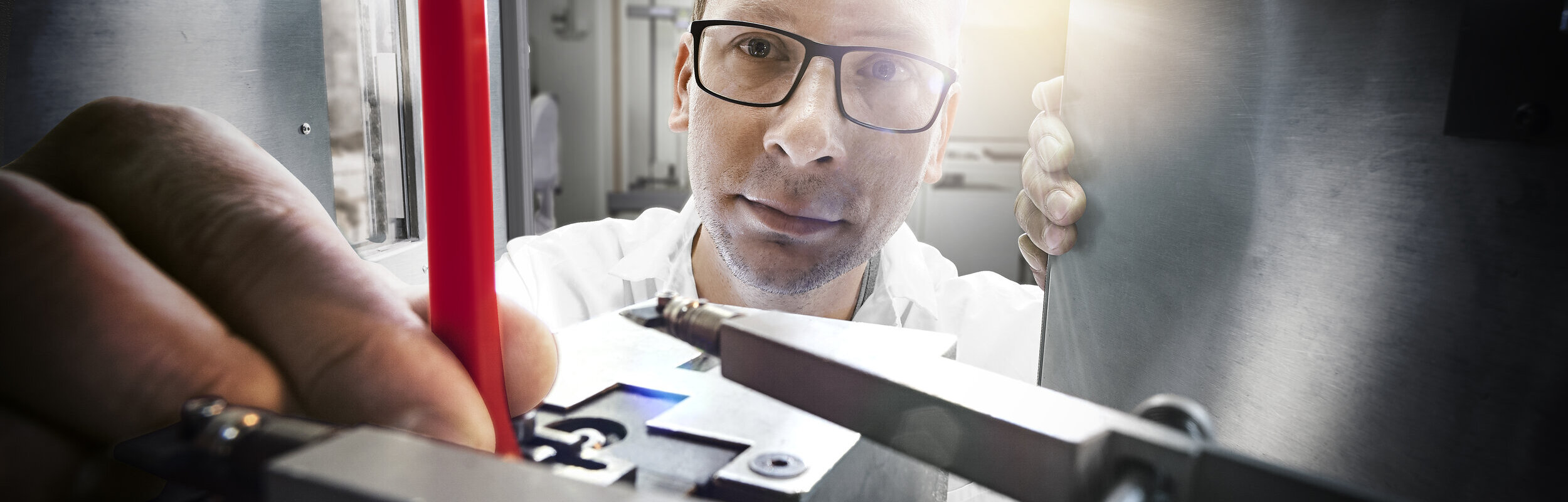

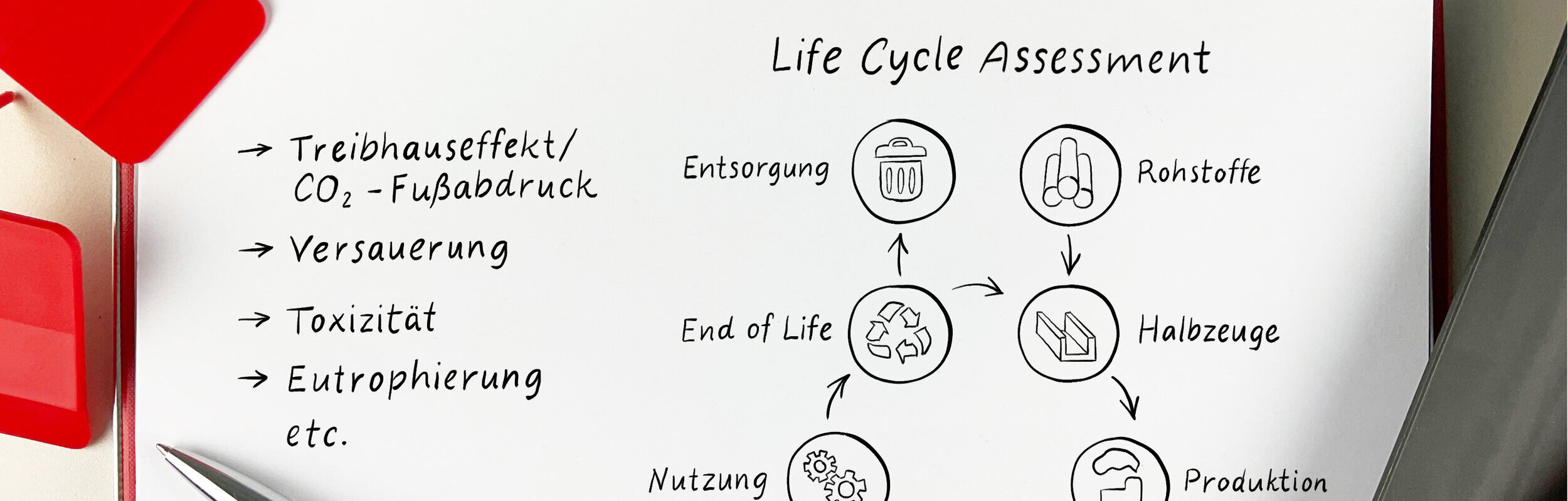

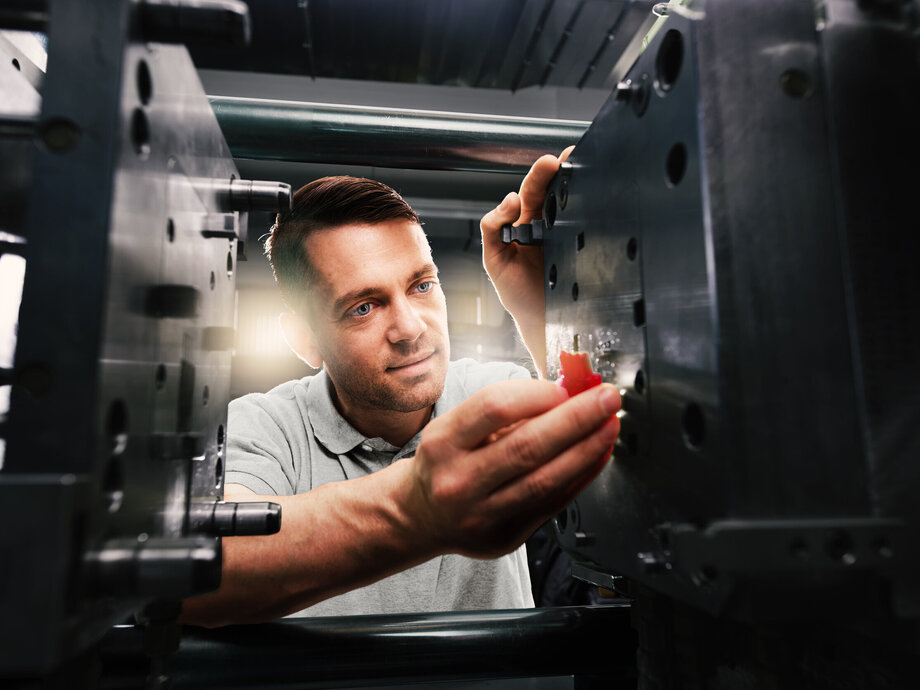

The main advantage of thermoplastic foam injection molding (TFIM) is the reduction in density and material. This also has a positive effect on the environment and economy. Density reduction can be achieved by chemical or physical foaming. Chemical foaming as an established process can be realized quickly and easily by metering a chemical blowing agent. For this purpose, a standard injection molding machine is used with minor machine modifications. Physical foaming offers even greater lightweighting potential compared with chemical foaming. Here, the blowing fluid requires special machine technology. The Cellmould® unit of the Battenfeld HM-MK 180/525H/350V is available for this purpose in the technical center of the KUZ. This machine can produce lightweight components in both 1K and 2K operation.

Our foam injection molding services in detail

Realize lightweight solutions

- Injection molding tests for foaming on our Battenfeld injection molding machine with Cellmould® unit

- Investigations into application-specific material combinations with the aim of achieving a lightweight construction effect

- Development of relevant process parameters

- Injection molding tests in 2K sandwich molding with foam core

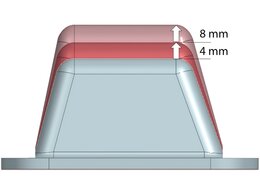

- Reduction of foam density by expansion stroke

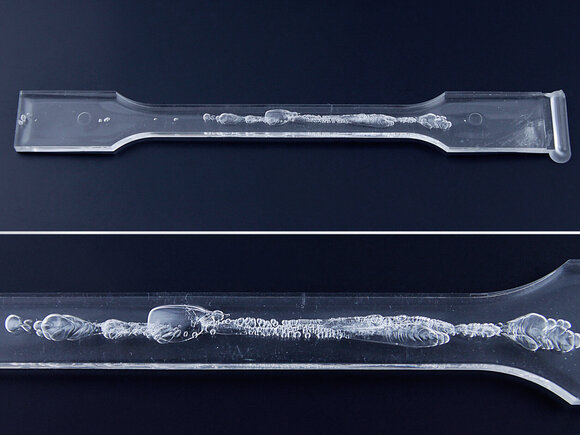

- Test engineering evaluation of the finished parts or test specimens in the accredited test laboratory

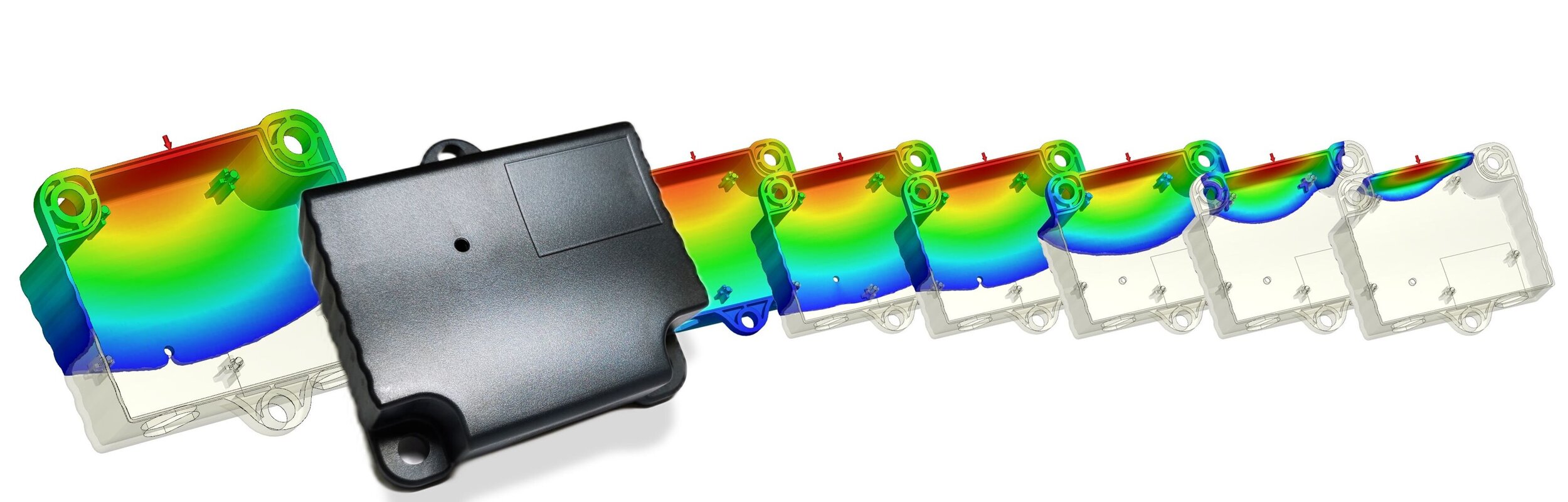

Foam injection molding and sandwich effect combined

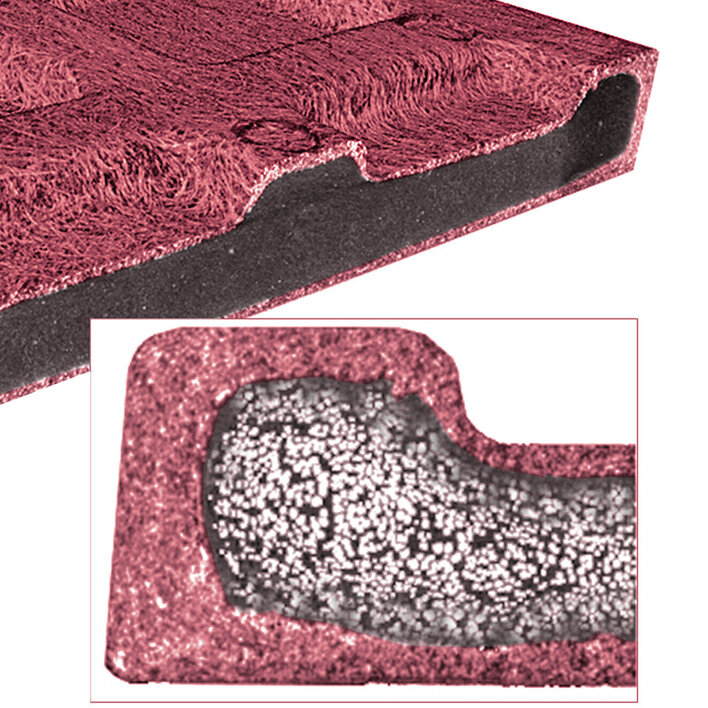

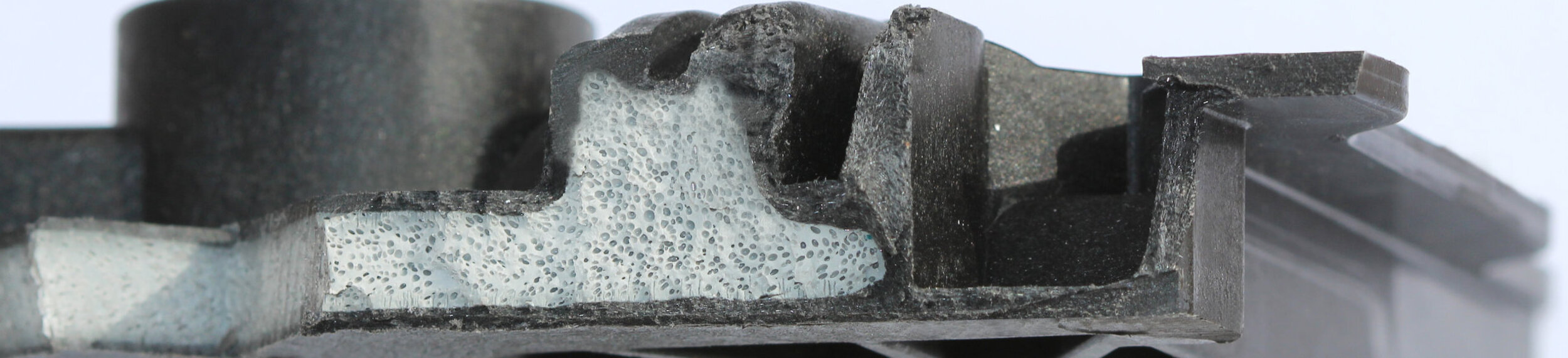

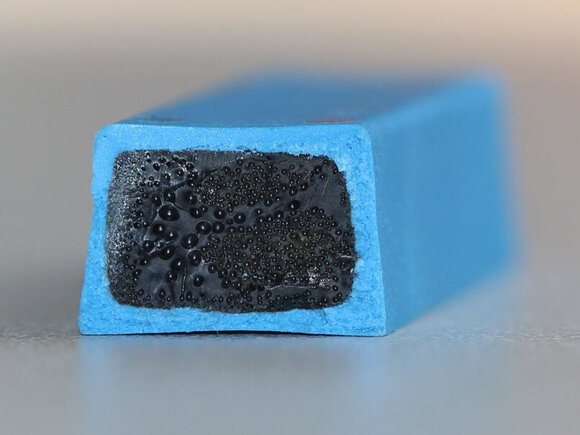

The sandwich effect causes the layers of a component furthest from the neutral axis to absorb the most bending forces. The closer the material layers are to the neutral axis, the lower the bending stresses and the lighter the foam can become in terms of lightweight construction. Ideally, the largest bubbles are located in the area of the neutral axis. In the direction of the edge layer, they become continuously smaller. Such a foam structure is called integral skin foam. Integral foam often forms during the chemical or physical foaming of thermoplastics: during injection, the melt solidifies immediately at the cavity wall, which impedes the formation of bubbles. The melt inside the component, on the other hand, cools only slowly, which promotes the formation of larger bubbles. A particularly rigid design using 2-component foam injection molding is possible with a combination of metal substitute plastic in the stiffness-relevant skin layer and a lightweight foam core, which acts as a shear-resistant spacer. The sandwich components can be mass-produced using a one-shot process and thus at low cost. The constructive application of the sandwich effect allows a lower weight for components that are mainly exposed to bending loads. As a special contribution to the circular economy and thus to sustainability, recycled material can be used in the core layer (2-component injection molding), as this is encapsulated by the compact, visually flawless skin material.

Our machine equipment at a glance

2 components injection molding machine

Battenfeld HM-MK 180/750H/350V

WITTMANN BATTENFELD Germany GmbH

Additional equipment gas flushing unit

CELLMOULD®

WITTMANN BATTENFELD Germany GmbH

Additional equipment mold plate

2K sandwich intermediate plate

A & E Produktionstechnik GmbH

"/>

"/>