Combination injection molding reaction technology

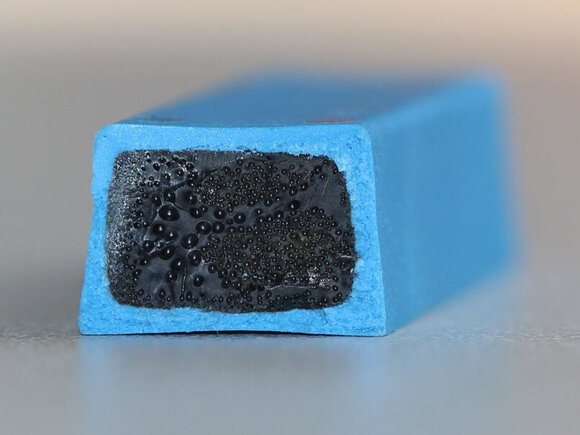

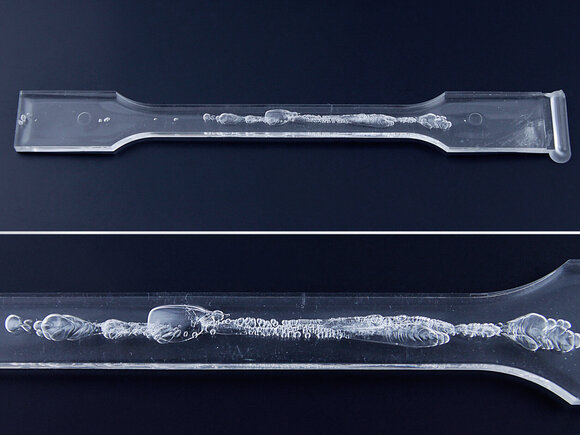

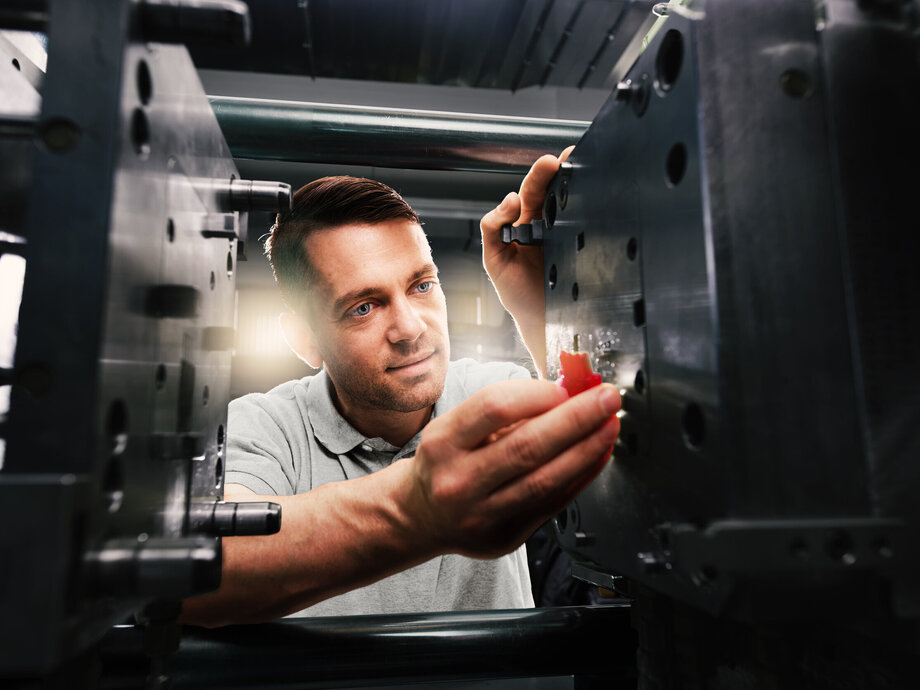

With the technology platform for the process combination of thermoplastic and reaction injection molding, we bring together two of our technological core competencies to open up new potential for you. This process combination is based on the manufacturing principles of the classic multi-component injection molding process, whereby a reactive PUR or polyurea mixture is introduced into the mold cavity as the second component and bonds firmly with the freshly molded thermoplastic carrier during crosslinking.

Visible and functional surfaces of three-dimensionally molded thermoplastic components can thus be efficiently finished with high-quality coatings. The thermoplastic components thus benefit from the noble high-gloss appearance with a good depth effect and from the insensitive surface properties of the crosslinked systems, right through to self-healing in the event of minor damage. As a result of the versatility of the PUR or polyurea systems used for this purpose, hardly any wishes remain unfulfilled.

Our services for injection molding reaction process technology in detail

Our machine equipment at a glance

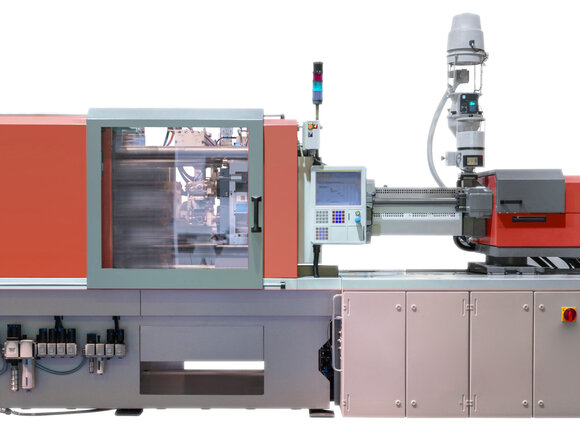

Injection molding machine with removal handling

KM 160/750 CX

KraussMaffei Group GmbH

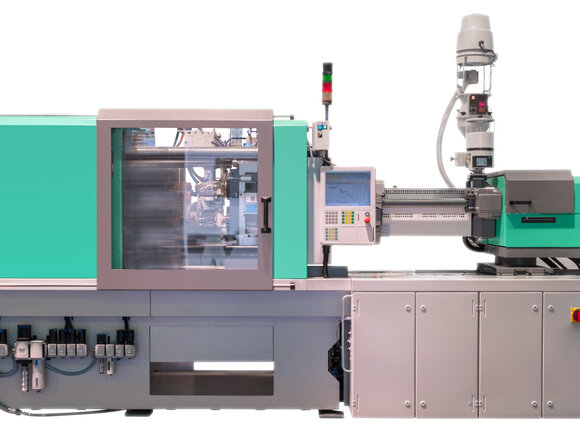

High pressure machine

RIM-Star Compact 8/8

KraussMaffei Group GmbH

"/>

"/>